Kyocera TASKalfa 5551ci Printing System (11),(12),(13),(14) Color Reference G - Page 67

Understanding color gamut, Printing techniques, gamuts, process colors, gamut mapping

|

View all Kyocera TASKalfa 5551ci manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 67 highlights

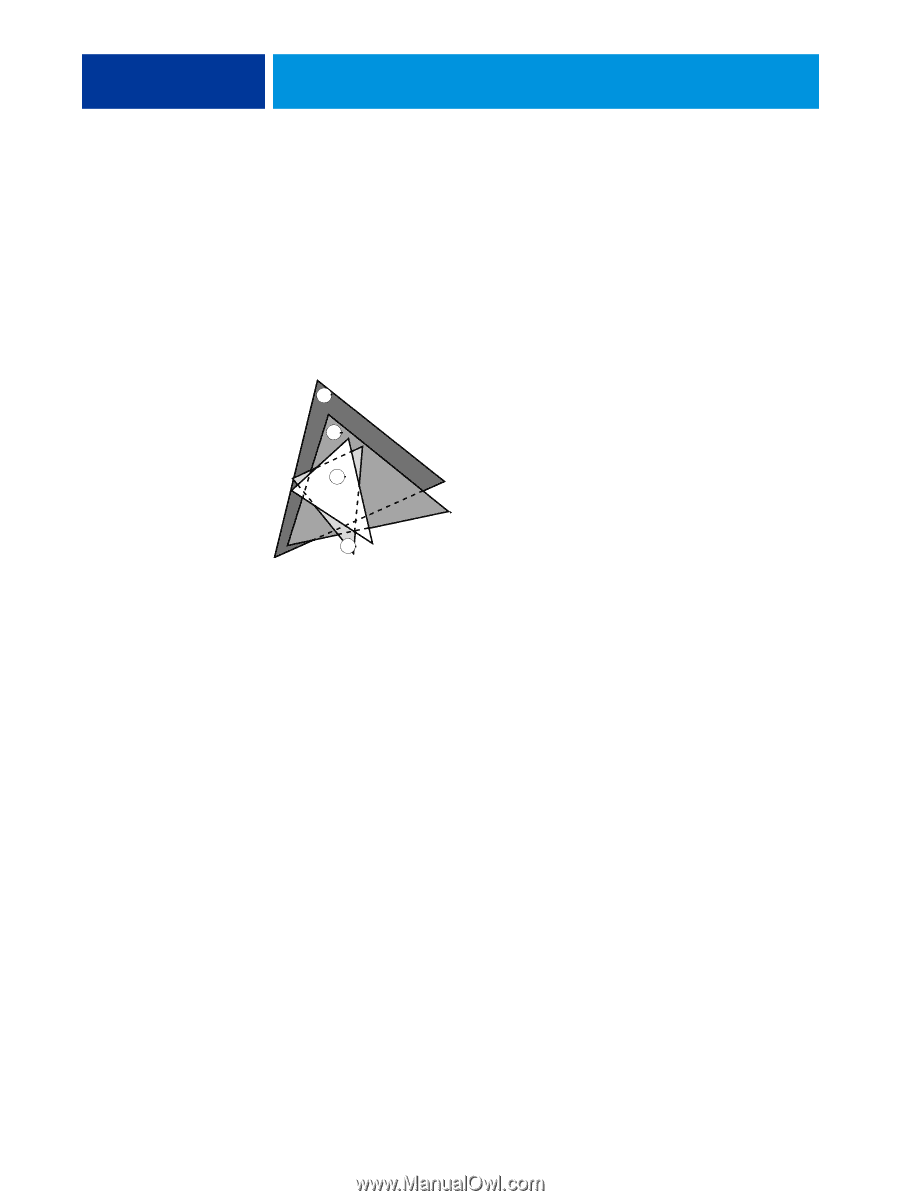

DESKTOP COLOR PRIMER 67 Understanding color gamut Different color reproduction techniques have different color capabilities, or gamuts. Color transparency films have comparatively large gamuts, as do color monitors. The color gamut that can be produced using process inks or CMYK toners on paper is smaller. This is why some colors that can be displayed on a color monitor, especially bright saturated colors, cannot be reproduced exactly by your Color Server, nor can they be reproduced on a press using process colors. Moreover, different printers have different gamuts. Some colors your printer can produce cannot be reproduced on an offset press, and vice versa. The following figure illustrates this concept of differing gamuts. 1 Color transparency film 2 RGB monitor 1 3 Offset press (white) 4 Other print device 2 3 4 You must account for the gamut of your printer when designing on a color monitor. When printed, colors that fall outside the printer gamut are "mapped" to printable colors. This process, referred to as gamut mapping, takes place when color data is converted or adjusted to meet the gamut requirements of a printer. The Color Server is specially designed to perform gamut mapping at high speed with high-quality results. It provides these color management features automatically, using either built-in default settings or settings you select for a particular print job. For added flexibility, you can also use the Color Server color management system in combination with the color management systems on Windows and Mac OS computers. Printing techniques Until recently, most color printing was done on printing presses using one of several printing techniques, such as offset lithography, flexography, or gravure. All traditional printing techniques require lengthy preparation before a press run can take place. Short-run color printing, including Color Server printing, eliminates most of this preparation. By streamlining the process of color printing, the Color Server makes short print runs economically feasible. In contemporary offset lithographic printing, digital files from desktop computers are output to an imagesetter, which creates film separations. The film is used to make a prepress proof, which is an accurate predictor of the final print job and allows you to make corrections before going to press. Once the proof is approved, the printer makes plates from the film and runs the print job on the press.