LG DLGX3901W Owners Manual - Page 22

High-Altitude Installations, Proceed to Venting the Dryer.

|

View all LG DLGX3901W manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

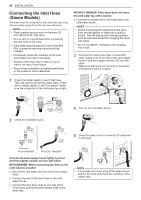

22 INSTALLATION NOTE • In the Commonwealth of Massachusetts: This product must be installed by a licensed plumber or gas fitter. When using ball-type gas shut off valves, they shall be T-handle-type. A flexible gas connector, when used, must not exceed 3 feet. This dryer is configured from the factory for natural gas (NG). If the dryer is to be used with propane (LP) gas, it must be converted by a qualified service technician. 1 Make sure that the gas supply to the laundry room is turned OFF and the dryer is unplugged. Confirm that the type of gas available in your laundry room is appropriate for the dryer. 2 Remove the shipping cap from the gas fitting at the back of the dryer. Be careful not to damage the threads of the gas connector when removing the shipping cap. 3 Connect the dryer to your laundry room's gas supply using a new flexible stainless steel connector with a 3/8-inch NPT fitting. NOTE • DO NOT use old connectors. 4 Securely tighten all connections between the dryer and your laundry room's gas supply. 5 Turn on your laundry room's gas supply. 6 Check all pipe connections (both internal and external) for gas leaks with a noncorrosive leakdetection fluid. 7 Proceed to Venting the Dryer. 3/8" NPT gas Connection AGA/CSA-Certified Stainless Steel Flexible Connector 1/8" NPT Pipe Plug Gas Supply Shutoff Valve High-Altitude Installations The BTU rating of this dryer is AGA-certified for elevations below 10,000 feet. If your gas dryer is being installed at an elevation above 10,000 feet, it must be derated by a qualified technician or gas supplier.