Lexmark 502n Card Stock & Label Guide - Page 121

Maintenance procedures, Forms supported 11-inch card stock and label trays, Media specifications

|

UPC - 734646054515

View all Lexmark 502n manuals

Add to My Manuals

Save this manual to your list of manuals |

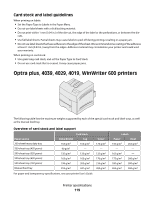

Page 121 highlights

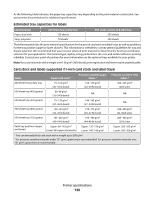

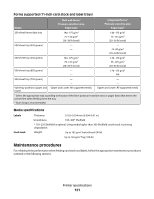

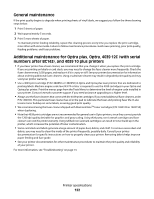

Forms supported (11-inch card stock and label trays) Media Dual web forms1 Pressure-sensitive area Paper base Integrated forms1 Pressure-sensitive area Paper base2 200-sheet heavy duty tray 140-175 g/m2 75-135 g/m2 (20-36 lb bond) 140-175 g/m2 75-135 g/m2 (20-36 lb bond) 500-sheet tray (450 grams) - - - 75-90 g/m2 (20-24 lb bond) 500-sheet tray (550 grams) 140-175 g/m2 75-131 g/m2 (20-35 lb bond) 140-170 g/m2 75-135 g/m2 (20-36 lb bond) 500-sheet tray (650 grams) - - 170-175 g/m2 NA 500-sheet tray (750 grams) - - - - Valid tray positions (upper and Upper and Lower: All supported media lower) Upper and Lower: All supported media 1 Select the appropriate tray according to the part of the form (pressure-sensitive area or paper base) that enters the printer first when feeding from the tray. 2 Grain long is recommended. Media specifications Labels Card stock Thickness: 0.102-0.254 mm (0.004-0.01 in.) Smoothness: 100-400* Sheffield * 150-250 Sheffield is optimal. Using media higher than 300 Sheffield could result in printing degradation. Weight: Up to 163 g/m2 Index Bristol (90 lb) Up to 163 g/m2 Tag (100 lb) Maintenance procedures For reliable printer performance when feeding card stock and labels, follow the appropriate maintenance procedures outlined in the following sections. Printer specifications 121