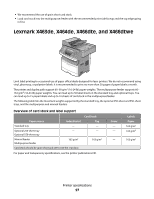

Lexmark X644E Card Stock & Label Guide - Page 93

use preprinted card stock manufactured with chemicals that may contaminate the printer. Preprinting

|

UPC - 734646093156

View all Lexmark X644E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 93 highlights

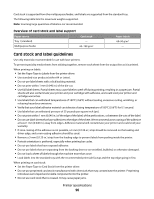

• If zone coating of the adhesive is not possible, a 3-mm (0.125-in.) strip should be removed on the leading and driver edge, and a non-oozing adhesive should be used. • Remove a 3-mm (0.125-in.) strip from the leading edge to prevent labels from peeling inside the printer. • Portrait orientation is preferred, especially when printing bar codes. • Do not use labels that have exposed adhesive. • Do not use labels that are separating from the backing sheet or are wrinkled, bubbled, or otherwise damaged. • Do not load a sheet of labels through the machine more than once. • Load labels into the manual bypass feeder with the recommended print side faceup and the top edge going in first. When printing on card stock: • Set the Paper Type to Card Stock from the printer driver. • Do not use preprinted card stock manufactured with chemicals that may contaminate the printer. Preprinting introduces semi-liquid and volatile components into the printer. • Do not use card stock that is creased. It may cause paper jams. • We recommend the use of grain short card stock. • Load card stock into the manual bypass feeder with the recommended print side faceup and the top edge going in first. Printer specifications 93