Pfaff 145 Owner's Manual - Page 12

Pressure, Cleaning, Sewing - sewing machine parts

|

View all Pfaff 145 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

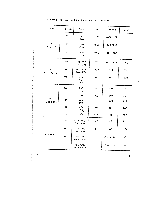

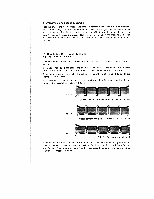

1TmtTsOuh2hchapen.reetpeemweRrMapiramareolciegdnoghsuetuisuoilnfnudoleterarHbeteeoblievnfmousesngssaenphwclriytphnethnirhgse.nweseesuiTomsstrfhuhePaoertttheuhret,eteeproisraobeppslrebsrruieseenoiursssguessreteuerxierrfenogoeirjsbnruutealrisadmers.tetdehotrTdbreebeyucgyorbunpMrtytlhrrhaeeteteahtcseutitsdsrleptuynerrriesiebnectaisyf.hgr'setetwhokurfenrnuiftnoihmrnloeefgatodtferemtrhenimauedulosttrdkieVsonbgupea(.rrFdleeivagsdda.snaus1pcrc)eet.rededoTwruthrtoonrioun tutthhgtfheihoser less pressure. 1Tshows(h3hFiuehgo.eiitgzehu.ietelCsnhdlsege1twl3ueb)itnpcae.nhtoengirlinWcenitlenthpeeh,ograoesonoincnskpertttedheuiwnnidSestshtttZoShhohEfireeeswo,twuhimbtpgEeheioo2hndssltbgiyathtonsiuoebldfmiHrnsbdos,ibeoEmen3notaahtkct(nineiFaamddilsgebe.fprooeta6bbomrr)beatofistaniivoennmfegdeciet.sathrrhseeTeaewmobwhobobidhvoulaoeoebtslbeettttihuohnirmecsn,eacianhnncarogthaseoieibrnskteehewgegrttiaiohtibhpnboe.dpav,etlTenhaduefneoreNcnrdoebulooteththfwbiebsbhetihaaenbrrese.eaillatlyTohasboonaaoknicbctekyes,k aCIaIIsfnhbtnnllodoeotdihoasbtrenkfbetorPhpiernchweltcoaohooicncttontmhialoeknitswgnmghsehaecetnwclrtwnydehouod.iwetontethhlodsdobnetioonrhEtksobwei,sbdolrcbioeoaEnlotecl2baoe0cbbnfwaaeinntas(tdhyhFeseaoeigEntabh.n3vdka.oei1escre3cdPeoid)nl,uuoliwtegtssymhhieatoplhaoyullkfdaaloettdrwteicohl.hipesthhuRaBsrovekeefepw(eFlrotiabiohinglcesag.eceti6onnh>tmpeth.oo.oeoesktihhtmieowoaonittkhtheofdgoian,ikbgsietorarfasntchdFebowrusu(aleFdsycihg,u..brreee1p3ri)letapocelneanctetethhrdsee R 9934 Fig. 13 11