Ryobi RY3716 Operation Manual - Page 28

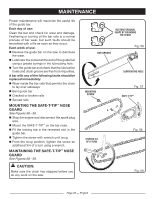

Hold the tip of the guide bar up and tighten, the bar mounting nuts securely.

|

View all Ryobi RY3716 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

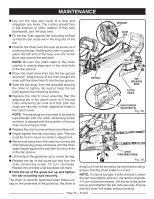

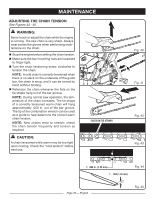

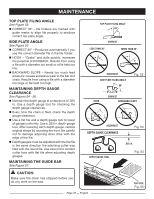

MAINTENANCE n Lay out the new saw chain in a loop and straighten any kinks. The cutters should face in the direction of chain rotation. If they face backwards, turn the loop over. n Fit the bar flush against the mounting surface so that the bar studs are in the long slot of the bar. SPROCKET GUIDE BAR n Position the chain over the nose as shown so it is behind the bar. Holding the chain in position, place the left end of the loop over the clutch drum and around the sprocket. NOTE: Be sure the chain rests in the chain catcher to ensure alignment of the drive links in the bar groove. n Place the chain drive links into the bar groove as shown. Slide the top of the chain toward the nose until the drive links fit into the bar groove. n Slide the bar away from the sprocket allowing the chain to tighten. Be sure to keep the bar flush against the mounting surface. n Replace the clutch cover ensuring that the adjusting pin in the clutch cover is in the bar chain tensioning pin hole and that both bar studs are securely in their respective holes in the clutch cover. NOTE: The adjusting pin may need to be slightly repositioned with the chain tensioning screw so that it is aligned with the position of the bar chain tensioning pin hole. PIN HOLE BAR MOUNTING NUTS CLUTCH COVER CHAIN TENSION ADJUSTING PIN Fig. 38 n Replace the clutch cover and bar mounting nuts. n Finger-tighten the bar mounting nuts. The bar must be free to move for tension adjustment. n Remove all slack from the chain by turning the chain tensioning screw clockwise until the chain seats snugly against the bar with the drive links in the bar groove. n Lift the tip of the guide bar up to check for sag. n Release the tip of the guide bar and turn the chain tensioning screw 1/2 turn clockwise. Repeat this process until sag does not exist. n Hold the tip of the guide bar up and tighten the bar mounting nuts securely. The chain is correctly tensioned when there is no sag on the underside of the guide bar, the chain is CHAIN TENSIONING SCREW Fig. 39 snug, but it can be turned by hand without binding. Ensure that the chain brake is not set. NOTE: If chain is too tight, it will not rotate. Loosen the bar nuts slightly and turn the tension adjuster 1/4 turn counterclockwise. Lift the tip of the guide bar up and retighten the bar nuts securely. Ensure that the chain will rotate without binding. Page 28 - English