Sanyo VR-L4110WSEC Booklet - Page 13

Sterilization and Decontamination, Control and Monitoring, Control, Temperature and, Humidity

|

View all Sanyo VR-L4110WSEC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

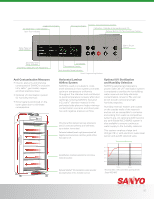

Control and Monitoring • The Sterisonic™ GxP control and informa- tion center includes an intuitive pop-up menu, high resolution LCD for inputs, outputs and performance at-a-glance. • Multi-point data logging offers pushbutton graphical display. An optional PC interface permits remote transmission for GMP/GLP protocols as required. • Precise P.I.D. logic controls and adjusts to all temperature and CO2 setpoints and alarm parameters. Sterilization and Decontamination • The unique Sterisonic™ GxP H2O2 sterilization system limits downtime to less than three hours when total chamber sterilization with verification is desired. • All interior components and CO2 sampling loop are sterilized in situ; no need for removal and autoclaving. • Continuous Active Background Contamination Control™ fights contamination while cell culture protocols are in process. CO2 Control • SANYO proprietary single-beam, dual detector infrared (IR2) CO2 sensor delivers precise CO2 control, quick recovery following door openings, and auto sampling with no moving parts. Temperature and Humidity Control • The patented Direct Heat and Air™ conditioning system manages setpoint temperature through multiple, variable warming points under microprocessor control. • The humidity pan is easy to fill, easy to clean; the automatic optical sensor advises of low water level. The Sterisonic™ GxP integrated microprocessor controller with LCD graphical display simplifies all incubator functions. Stable temperature and humidity conditions are achieved through a combination of performance systems supervised by the controller complete with alarm, programming, calibration and diagnostic protocols. A continuous Active Background Contamination Control™ process eliminates contamination without downtime. At the base of the plenum an isolated beam of high intensity, ozone-free ultraviolet light destroys contaminants in the air and in the humidity water reservoir, away from active cell cultures. The patented Direct Heat and Air Jacket™ heating system distributes proportional energy to the interior chamber through a natural convection air jacket surrounded by a high-density insulation to protect against ambient temperature fluctuations. 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Finish. Incubator must cool from high heat temperatures to near ambient. 13