Sharp AR-RB1 Service Manual - Page 11

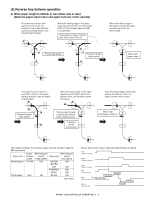

B. When the paper length is 250mm or more B5R or more, The paper input motor, upper turnover motor

|

View all Sharp AR-RB1 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

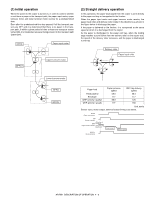

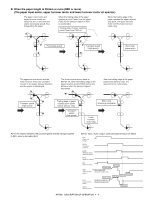

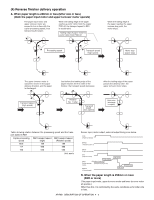

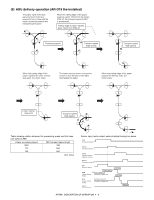

B. When the paper length is 250mm or more (B5R or more) (The paper input motor, upper turnover motor and lower turnover motor all operate.) The paper input motor and upper turnover motor are caused to turn in time with the copier processing speed, thus transporting the paper. When the trailing edge of the paper reaches a point 13mm from the copier POD off, the transport speed in RB1 is accelerated. Trailing edge of paper reaches point 13mm from POD off When the trailing edge of the paper reaches the upper reverse stop point, the upper turnover motor and the lower turnover motor stop. Processing speed Transport speed (high speed) Motor stop (paper stop) The upper turnover motor and the lower turnover motor are caused to revolve in the paper delivery direction, and the paper is discharged. The lower reverse motor stops at BPPD1 off, when the trailing edge of the paper reaches a point 50mm before the delivery roller, the transport speed decreases. After the trailing edge of the paper passes the delivery roller, the upper turnover motor stops. Transport speed (high speed) Trailing edge of paper reaches point 50mm before delivery roller Transport speed (low speed) Motor stop (discharge complete) Lower turnover motor stop As for the relation between the process speed and the transport speed in RB1, refer to the table (3)-A. Sensor input, motor output, solenoid output timing is as below. POD (Paper exit sensor) BPPD1 (Transport sensor 1) BPRD (Reverse section detection sensor) BPOD (Paper-out sensor) BIM (Paper-in motor) Process speed BRM (Direction of paper-in) (Upper reverse motor) (Direction of paper-out) BTM (Lower reverse motor) BGSOL (Gate solenoid) Process speed (Direction of paper-in) (Direction of paper-out) High speed Low speed High speed High speed High speed AR-RB1 DESCRIPTION OF OPERATION 4 - 4