Troy-Bilt Pony CRT Operation Manual - Page 19

Lubrication, Adjustments

|

View all Troy-Bilt Pony CRT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

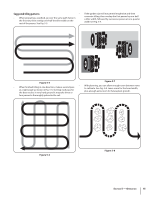

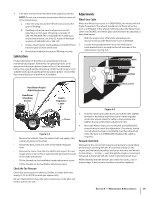

4. If oil does not flow from the check hole, add oil as follows: NOTE: Do not use automatic transmission fluid or motor oil in the transmission. a. Clean the area around the fill hole and unscrew the gear oil fill plug. b. If adding only a few ounces of gear oil, use API rated GL-4 or GL-5 gear oil having a viscosity of SAE 140, SAE 85W-140 or SAE 80W-90. If refilling an empty transmission, use only GL-4 gear oil having a viscosity of SAE 85W-140 or SAE 140. c. Using a clean funnel, slowly add gear oil until it flows from the gear oil level check hole. d. Reinstall and tighten the gear oil fill plug securely. Lubrication Proper lubrication of the tiller is an essential part of your maintenance program. After every 10 operating hours, oil or grease the lubrication points shown in Fig. 6-2 as described below. Use a good quality lubricating oil (#30 weight engine oil is suitable) and a good quality general purpose grease. Grease that has a metal lubricant is preferred, if available. Adjustments Wheel Gear Cable When the Wheel Gear Lever is in DISENGAGE, the wheels will roll freely (freewheel). The wheels should not roll freely when the lever is in ENGAGE. If the wheels roll freely when the Wheel Gear Lever is in ENGAGE, the wheel gear cable needs to be adjusted as described below. 1. With the engine shut off and the spark plug wire disconnected, put the Wheel Gear Lever in ENGAGE. 2. Loosen the top adjustment nut on the wheel gear cable bracket that is located on the left side rear of the transmission. See Fig. 6-3. Wheel Gear Cable Adjustment Nut Adjustment Nut Handlebar Height Adjusting Screws Handlebar Attaching Screws Depth Regulator Lever Eccentric Lever Tines Wheel Shaft Figure 6-2 • Remove the wheels, clean the wheel shaft and apply a thin coating of grease to the shaft. • Grease the back, front and sides of the depth regulator lever. • Remove the tines, clean the tine shafts and inspect for rust, rough spots or burrs. File or sand smooth and coat the ends of the shaft with grease. • Oil the threads on the handlebar height adjustment screw. • Oil the threads on the handlebar attaching screws. Check the Tire Pressure Check the air pressure in both tires. Deflate or inflate both tires evenly to 15-to-20 PSI (pounds per square inch). Be sure that both tires have the same air pressure or the tiller will tend to pull to one side. Figure 6-3 3. Push the wheel gear cable down and roll the tiller slightly forward or backward until the eccentric lever engages (locks) the wheels. Hold the cable in that position and tighten the top and bottom adjustment nuts. 4. Move the Wheel Gear Lever to ENGAGE and DISENGAGE several times to check the adjustment. The wheels should not roll when the lever is in ENGAGE, but they should roll when the lever is in DISENGAGE. Readjust the cable as required. Forward Clutch Belt Maintaining the correct belt tension is important to good tilling performance and long belt life. A loose belt will slip on the engine and transmission pulleys and cause the tines and wheels to slow down - or stop - even though the engine is running at full speed. A loose belt will also result in premature belt wear. While checking the belt tension, also check for cracks, cuts or frayed edges. A belt in poor condition should be replaced. Section 6 - Maintenance & Adjustments 19