Bernina 742 Manual - Page 71

responding

|

View all Bernina 742 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 71 highlights

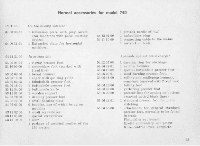

HOW TO AVOID MACHINE TROUBLE First of all we should like to give you some hints how machine troubles might be avoided, then what may be their cause, and finally how to remedy them. I. On principle In most cases troubles are resulting from faulty manipulationa of the sewing machine. However, if other causes arc presumed, the machine should be examined, whether: a) the needle has been correctly inserted. The long groove should always be In front, i.e. on the side where the machine has to be threaded ; b) the needle is the correct size for the thread used; for darning of fine fabrics take needle mire no. 70. and for other sewing work needle size no. 80 or no. 90. As regards sizes of needles with corresponding threads see page 13; c) The machine is properly cleaned. Remove free arm cover plate and clean all lint thereunder. Then cleanse feed dog with brush; d) shuttle is properly cleaned with but a few drops of oil (see fig. 181: c) no thread ends arc stuck between the thread tension discs; f) no thread ends are jammed under the bobbin ease tension spring: g) the sewing machine can easily he alerted with the handhweel. Noir; Make if a ricir oilcans to raise firreott talcr-up lever to its newest position: it will help to avoid lot !), ainehint froribteA. 2. The causes of upper thread breaking may be the following: a) The use of badly polished needles of inferior Quality. Needles should always be purchased at a Bernina shop; bl Needle incorrectly set. Remember that long groove must always be in front ; c) Needle in blunt or bent; d) The relation ebtween size of thread and needle is not o. k. (see table on page IS): et Upper tension thread is too tight; 70