Bosch 1194AVSR Operating Instructions - Page 7

Bosch 1194AVSR - Hammer Drill 1/2in Dual Torque VSR Manual

|

UPC - 000346314830

View all Bosch 1194AVSR manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

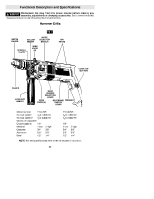

Operating Instructions TRIGGER CONTROLLED VARIABLE SPEED Your tool is equipped with a variable speed trigger switch. The tool speed can be controlled from minimum to maximum nameplate rated RPM by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed (Fig. 1). "LOCK-ON" BUTTON The "Lock-ON" button, located in the handle of your tool allows for continuous operation at maximum RPM without holding the trigger. TO LOCK TRIGGER "ON": squeeze trigger, depress button and release trigger. TO UNLOCK THE TRIGGER: squeeze trigger and release it without depressing the "LockON" button. ! WARNING continuously being depressed, the trigger can not be released. REVERSING SWITCH LEVER The reversing switch lever is located above the trigger switch and is used to reverse rotation of the bit. The reversing switch should only be activated when the motor is "OFF" and when bit is at a complete standstill (Fig. 1). To use tool in "Forward" rotation move lever to left side of tool, to "Reverse" the rotation of the bit move the lever to the right side of the tool. Do not change direction of rotation until the tool comes to a complete stop. Shifting during rotation of the chuck can cause damage to the tool. If the "Lock-ON" button is ! CAUTION MODE SELECTOR SWITCH The mode selector switch allows the tool to be set for various drilling applications. Slide the switch right or left depending on the below applications (Fig. 1). Drill only action: For drilling in woods, metals, plastics or other non concrete materials. Drill with hammer action: For drilling in concrete, asphalt, tile or other similar hard materials. GEAR CHANGE SELECTION Gear selection: The proper gear selection is directly related to the speed and torque required for various jobs. The following should be adhered to when selecting the proper gear: Speed 1 = low speed with high torque Speed 2 = high speed with low torque Changing gears: Change gear position only with the motor at a complete standstill. To change gears rotate the gear selection lever. If you have difficulties changing from one gear to the other, turn the chuck by hand until the gears engage (Fig. 1). AUXILIARY HANDLE The auxiliary handle will provide additional control, support and guidance for the drill. The handle is adjustable to any position around the 360˚ handle collar mount. Installing side handle: Slide the handle over the handle collar mount. Securely tighten wing knob (A). DEPTH GAUGE Your drilling depth can be pre-set and/or repeated by using the depth gauge. Setting depth: After the auxiliary handle is installed, slide the depth gauge to desired depth and securely tighten wing knob (B). INSERTING BIT For small bits, open jaws enough to insert the bit up to the flutes. For large bits, insert the bit as far as it will go. Center the bit as you close the jaws by hand. This positions the bit properly, giving maximum contact between the chuck jaws and the bit shank. To tighten chuck, insert key into each of the three key holes in succession and tighten clockwise firmly. The chuck can be released by using one hole only (Fig. 2). Clockwise Counter Clockwise FIG. 2 -7-