Brother International BAS-311G Instruction Manual - English - Page 72

Adjusting the thread wiper, 10-13. Presser foot installation position

|

View all Brother International BAS-311G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 72 highlights

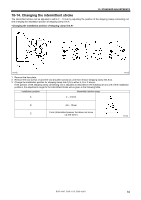

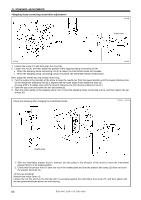

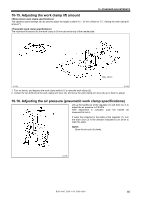

10. STANDARD ADJUSTMENTS 10-12. Adjusting the thread wiper Approx. 2mm 5007Q 5008Q Approx. 3mm 5009Q 1. Loosen the two screws (3) and shift the entire solenoid setting plate (4) up or down to adjust so that the thread wiper (2) is 15 mm in front of the needle center when the plunger (1) of the thread wiper solenoid is driven to the full stroke. 2. Loosen the screw (5) and adjust the position of the thread wiper (2) so that the distance from the thread wiper to the tip of the needle is approximately 2 mm and the tip of the thread wiper (2) is approximately 3 mm from the center of the needle when the thread wiper (2) passes below the needle during operation. Note: Check that the thread wiper (2) does not touch the finger guard. 10-13. Presser foot installation position Install the presser foot (1) with the screw (2) so that the distance from the bottom of the presser foot to the top of the needle plate is 22 mm when the sewing machine is stopped and the presser foot (1) is raised. 5031Q 63 BAS-300G, BAS-311G, BAS-326G