Brother International BES-116 Thread Tensions - English - Page 1

Brother International BES-116 Manual

|

View all Brother International BES-116 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 1 highlights

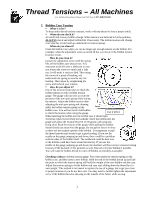

Thread Tensions - All Machines For Technical Assistance Please Call Toll Free 1-877-4BROTHER Below are items related to thread tensions and tension problems as found on Brother embroidery equipment. They are listed in the order that they most often occur. Use this form only as a guide. Following this guideline will help with proper tension adjustments to reduce puckering of the fabric and reduce thread breaks. For best results, use genuine Brother parts. 1. Anti - Spin Spring for Bobbin Case !" What is it for? Also called the "No Backlash Spring". It is used to keep the bobbin from spinning after the takeup lever has pulled the stitch tight. If allowed to spin this would cause the bobbin thread to be thrown out of the groove in the bobbin causing a very loose tension as the machine starts up again. Some may say they are not required on embroidery machines, but with the speeds achieved on Brother embroidery machines today, they do make a difference. Running the machine with out one may not cause an immediate problem, but they do make a difference and are needed in these types of machines with jumbo bobbins. It is strongly recommend when replacing one, to replace it with a Brother Anti-Spin Spring p/n#S35583001, which comes in the Brother bobbin case assembly p/n#S35584001. !" When do you check it? At installation of machine and at every bobbin change. !" How do you check it? Install a brand new bobbin, (for the correct weight), in the bobbin case. Hold bobbin case level with open side up or lay upside down on a table. The bobbin should be .5mm above the top of the bobbin case. I recommend the prewound, with two cardboard sides that have a serration on the flat surface of the cardboard. This helps slow down the bobbin when in machine. • How do you adjust it? Remove the spring by taking it out with a small slotted screwdriver. Note how you took the anti-spin spring out of the bobbin case to adjust it, as it will only go back in properly one way. You will need to bend the spring in two places so that the spring will be even against the bobbin as illustrated. Re-insert the spring and recheck your adjustment. Try to make it as even as possible all the way around the bobbin case. You may need to repeat this procedure a few times until it is correct. 1