Brother International BES-1260BC Motor Locks - English - Page 1

Brother International BES-1260BC Manual

|

View all Brother International BES-1260BC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 1 highlights

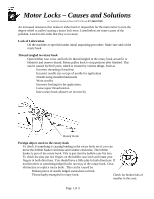

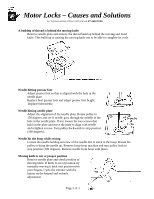

Motor Locks - Causes and Solutions For Technical Assistance Please Call Toll Free 1-877-4BROTHER An increased resistance that makes it either hard or impossible for the main motor to turn the degree wheel or pulley causing a motor lock error. Listed below are some causes of the problem. Listed in the order that they occur most. Lack of Lubrication • Oil the machine as specified under initial unpacking procedure. Make sure and oil the rotary hook. Thread tangled in rotary hook • Open bobbin case cover and look for thread tangled in the rotary hook around it or behind it and remove thread. Rotate pulley back to stop position after finished. This can be caused by bird's nest, which is created by various things. Such as • Incorrect threading of machine • Incorrect needle size or type of needle for application • Needle being installed backwards • Worn needles • Incorrect backing for the application. • Loose upper thread tension • Inner rotary hook adjuster set incorrectly Rotary Hook Foreign object stuck in the rotary hook To check if something is causing binding in the rotary hook see if you can move the bobbin basket clockwise and counter-clockwise. The bobbin basket is part of the rotary hook. This is part that the bobbin case fits into. To check the play put two fingers on the bobbin case latch and rotate your fingers in both directions. You should have a little play in both directions. If not then there is something lodged in the raceway of the rotary hook. Clear obstruction or replace rotary hook. This can be caused by • Broken pieces of needle lodged somewhere in hook • Thread badly entangled in rotary hook. Check for broken bits of needles in this area. Page 1 of 3