Brother International LS2-F52A Instruction Manual - English - Page 22

Adjusting, clearance, between, forked, connection, collar, height, presser

|

View all Brother International LS2-F52A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

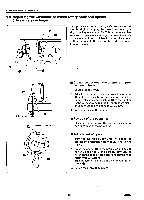

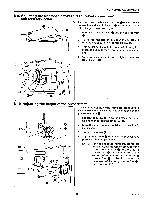

8. STANDARD ADJUSTMENTS 8-9. Adjusting the clearance between feed forked connection and feed fork collar Incorrect clearance between the fork Q of feed forked connection and feed fork collar Q will bring irregular stitch length or overheating, etc. 1. Remove the cover plate Q and the oil reservoir 2. To increase the clearance, loosen the nut Q and turn the nut Q to left or counter-clockwise. This adjustment should be done with turning the machine pulley toward you to get correct clearance. 3. Upon completion of adjustment, tighten the screw and screw 0. 8-10. Adjusting the height of the presser feet The standard height for the lifting presser foot Q is 8.5 mm when the presser foot has been raised by the presser bar lifter O. 1. Loosen the screw 0, raise the presser bar lifter 0, and then loosen the set screw G. 8.5mm 2. Move the lifting presser foot Q up or down to adjust its height. 3. Tighten the screw G. 4. Tighten the screw Q to adjust the presser foot pressure. (Refer to page 13.) NOTE: If the height of the lifting presser foot is changed, the movement amount of the lifting presser foot Q and vibrating presser foot Q will change. Adjust the amount of movement of the vibrating presser foot Q so that it matches the movement of the lifting presser foot O. (Refer to page 21.) O O O O - 20 - LS2-F52A