Craftsman 21833 Operation Manual - Page 6

Blade Guard Storage - cast table extension

|

View all Craftsman 21833 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

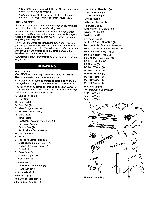

IMPORTANT: Table is coated with a protectant. To ensure proper fit and operation, remove coating. Coating is easily removed with mild solvents, such as mineral spirits, and a soft cloth. Avoid getting solution on paint or any of the rubber or plastic parts. Solvents may deteriorate these finishes. Use soap and water on paint, plastic or rubber components. After cleaning, cover all exposed surfaces with a light coating of oil. Paste wax is recommended for table top. WARNING: Never use highly volatile solvents. Non flammable solvents are recommended to avoid possible fire hazard. Refer to Figures 3, 4, 5, 7, 8, 9 and 10. CAUTION: Do not attempt assembly if parts are missing. Use this manual to order replacement parts. Be certain all parts are clean and free of shipping preservative. Also, completely remove all parts of packing. Saw cabinet should be directly on the floor. SAW INSTALLATION Positioning the saw on a level surface (shimming may be required) will improve stability and accuracy and prevent warpage and failure of cast components and welds. WARNING; Make certain that the saw is disconnected from the power source. ASSEMBLE THE MOBILE BASE Refer to Figure 12, page 24. NOTE: Finger tighten bolts and nuts until assembly of mobile base is complete. Then tighten all fasteners securely. • Use two M8 x 16 socket pan head bolts (Key No. 1) to attach a corner support bracket (Key No. 3) to each fixed support (Key Nos. 9 and 29) at the ends of one of the caster sets. • Repeat for the other caster set. ° Attach the front panel (Key No. 8 - stamped 'A') between the two corner supports attached to one of the caster sets using six M6 x I2 socket pan head bolts (Key No. 2). Note: Place the panel edges INSIDE the corner support surfaces. • Attach the rear panel (Key No. 8) between the two corner supports attached to the remaining caster set. = Attach the left side panel (Key No. 25 - stamped 'B') to the assemblies made in the previous two steps. • Attach the right side panel (Key No. 33 - stamped 'C') to the assembly made in the previous step. ASSEMBLE BASE TO CABINET Refer to Figures i0 and 12, pages 20 and 24. NOTE: Saw cabinet and base are very heavy. Two people are required to assemble this saw. ° Place a large sheet of cardboard or carpet on the floor to protect the table top. • Carefully place the saw cabinet upside down on the floor. ° Remove the six bolts and the back panel (Fig. 10, Key Nos. 2 and 24). This will allow you to adjust the cabinet holes to align with the base holes. ° Place the dust chute (Fig. 12, Key No. 30) on the cabinet with the chute facing upwards. ° Place the mobile base assembly onto the cabinet and dust chute and secure in position with four socket head bolts, lock washers and flat washers (Fig. 12, Key Nos. 10, 11 and 12). NOTE: The foot pedals of the caster sets face towards front and rear of cabinet, the push stick is attached to the left side of the base and rip fence hooks are on the right side of the base. • Press the four rubber feet (Fig. 12, Key No. 4) to the base legs. ° Turn the saw upright, reattach the back panel of the cabinet. HANDWHEEL ASSEMBLY Refer to Figure 13, page 26. WARNING: Make certain that the saw is disconnected from the power source. • Place one of the handwheels (Key No. 30) onto the blade raise/lower shaft (Key No. 56) located on the front of the cabinet. Align the groove in the back of the handwheel with the pin. ° Thread the locking knob (Key No. 27) onto the threaded end of the shaft. ° Repeat the steps above to assemble the remaining handwheel and locking knob onto the bevel shaft located on the right side of the cabinet. ATTACH LINE CORD HOOKS Refer to Figure 10, page 20. ° Tilt the table to 45°. ° Install the line cord hooks(Key No. 9) using sockethead bolts, washersand nuts (Key Nos. 10, 12 and 13) to the leftside of the saw cabinet. ASSEMBLE BLADE GUARD STORAGE BRACKETS Refer to Figure 12, page 24. Installthe blade guard storage brackets (Key Nos. 18 and 19) to the leftside pane[ (Key No. 25) of the base usingfour screws, lock washers and fiat washers (Key Nos. 15, 16 and 17). ASSEMBLE PUSH STICK STORAGE BRACKETS Refer to Figure 12, page 24. Installthe push stickstorage brackets (KeyNo. 23) to the left side panel (Key No. 25) of the base usingfour screws, lock washers and flat washers (Key Nos. 20, 2t and 22). ASSEMBLE RIP FENCE STORAGE BRACKETS Refer to Figure 12, page 24. Install the rip fence storage brackets (Key No. 34) to the right side panel (Key No. 33) of the base using two screws, flat washers and hex nuts (Key Nos. 14, 31 and 32). ATTACH EXTENSION TABLES Refer to Figure 11, page 22. ° Assemble extension table (Key No. 35) to the table using hex head bolts, lock washers and fiat washers (Key Nos. 36, 37 and 38). ° Hand tighten only. Do not tighten completely until tables are level. ° Repeat above procedure for the other extension table. 6