Dell PowerVault 130T DLT Dell DLT VS and SDLT Media Handbook - Page 17

Visual Media Inspection

|

View all Dell PowerVault 130T DLT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

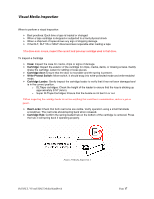

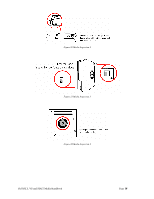

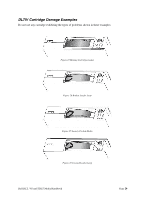

Visual Media Inspection When to perform a visual inspection Best practices: Each time a tape is loaded or changed When a tape cartridge is dropped or subjected to a hard physical shock When a shipment of tapes shows any sign of shipping damage If the DLT, DLT VS or SDLT drive becomes inoperable after loading a tape ! If a drive error occurs, inspect the current and previous cartridge used in that drive. To Inspect a Cartridge Case: Inspect the case for cracks, chips or signs of damage. Cartridge: Inspect the exterior of the cartridge for chips, cracks, dents, or missing screws. Gently shake the cartridge. Listen for rattling or loose pieces. Cartridge door: Ensure that the door is moveable and the spring is present. Write Protect Switch: Move switch. It should snap into write-protected mode and write-enabled mode. Cartridge Leader: Gently inspect the cartridge leader to verify that it has not been damaged and is in the correct position. o DLTtape cartridges: Check the height of the leader to ensure that the loop is sticking up approximately 3/16" (4mm). o Super DLTtape Cartridges: Ensure that the buckle is not bent in or out. ! When inspecting the cartridge leader do not use anything that could leave contamination, such as a pen or pencil. Reel Locks: Check that both reel locks are visible. Verify operation using a small flat-blade screwdriver. The reel locks should spring back when released. Cartridge Hub: Confirm the spring-loaded hub on the bottom of the cartridge is centered. Press the hub; it will spring back if operating properly. Figure 19 Media Inspection 1 Dell DLT, VS and SDLT Media Handbook Page 17