Dewalt D51236K Instruction Manual - Page 6

Warning:to Reduce The Risk Of Serious Personal Injury, Always Disconnect Air From Tool Before All - d51236

|

View all Dewalt D51236K manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

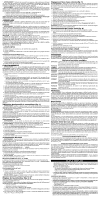

FIG. 9 FREE WARNING LABEL REPLACEMENT REMPLACEMENT GRATUIT DES ÉTIQUETTES D'AVERTISSEMENT SUSTITUCIÓN GRATUITA DE LAS ETIQUETAS DE ADVERTENCIA TOOL SPECIFICATIONS CARACTÉRISTIQUES DE L'OUTIL ESPECIFICACIONES DE LA HERRAMIENTA D51236 D51238 Height / Hauteur / Altura 8.2'' (209 mm) 8.5'' (215.9 mm) Width / Largeur / Anchura 2.6'' (67 mm) 2.8'' (58.4 mm) Length / Longueur / Longitud 9.6'' (245 mm) 9'' (228.6 mm) Weight / Poods / Peso 2.4 lbs. (1.1 kg) 2.8 lbs. (1.3 kg) Recommended Operating Pressure 70 - 120 psig (4.9 to 8.3 bar, 5 to 8.5 kg/cm2) 70 - 120 psig (4.9 to 8.3 bar, 5 to 8.5 kg/cm2) Pression de fonctionnement recommandée de 70 à 120 lb/po2 de 70 à 120 lb/po2 Presión de funcionamiento recomendada (de 5 à 8,5 kg/cm2 ou de 4,9 à 8,3 bar) (de 5 à 8,5 kg/cm2 ou de 4,9 à 8,3 bar) Air Consumption per 100 cycles Consommation d'air par 100 cycles Consumo de aire por cada 100 ciclos 2.1 cfm 2,1 cfm 2,1 cfm 3.5 cfm @ 100 psi 3,5 pi3/mn @ 100 lb/po2 3.5 cfm @ 100 psi Loading capacity Capacité de chargement Capacidad óptima Up to 110 Nails Jusqu'a 110 clous Hasta 110 clavos Up to 110 Nails Jusqu'a 110 clous Hasta 110 clavos Portable Handcarry 3.2 - 4 CFM Portable à la main 3,2 à 4 pi3/min Transporta ble 3.2 - 4 CFM 5.5 HP Gas 2 HP Elec. 8 - 9 CFM 5,5 HP Essence 2 HP Élec. 8 à 9 pi3/min 5.5 CV Gas 2 CV Elec. 8 - 9 CFM 8 HP Gas 14 - 16 CFM 8 HP Essence 14 à 16 pi3/min 8 HP Gas 14 -16 CFM Industrial 23+ CFM Industriel 23 pi3/min + Industrial 23+ CFM NUMBER OF TOOLS CONNECTED TO COMPRESSOR NOMBRE D'OUTILS RACCORDÉS AU COMPRESSEUR NÚMERO DE HERRAMIENTAS CONECTADAS AL COMPRESOR 1 2 3 Compressor will be sufficient for tools at all production rates. Le compresseur sera suffisant pour les outils à tous les taux de production. 4 El compresor será suficiente para las herramientas a cualquier velocidad de trabajo Compressor will be sufficient at slow or moderate production rates, but may have difficulty at very rapid rates. 5 Le compresseur est suffisant pour les cadences de production lentes ou modérées, mais son rendement pourrait être insuffisant pour les cadences très rapides. El compresor será suficiente a velocidades de trabajo bajas o moderadas, pero puede tener dificultades en velocidades muy rápidas. 6 Compressor will be adequate only when tools are utilized at slow production rates. (punch-out or occasional use) Le compresseur est adéquat uniquement quand les outils sont utilisés à des cadences de production lentes (perforation ou utilisation occasionnelle). 7 El compresor sólo será adecuado cuando las herramientas se utilicen en velocidades de trabajo lentas (perforación o uso ocasional). Not Recommended Non recommandé 8+ No recomendado Troubleshooting Guide MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS, CONTACT A DEWALT SERVICE CENTER OR CALL 1-(800)-4-DEWALT. WARNING: TO REDUCE THE RISK OF SERIOUS PERSONAL INJURY, ALWAYS DISCONNECT AIR FROM TOOL BEFORE ALL REPAIRS. D51236 Cat. # Trigger valve housing leaks O-ring or valve stem failure Replace valve using: Trigger Valve Kit D510005 Top cap leaks air Loose cap screws Tighten cap screws using appropriate Allen wrench Damaged or worn gasket or o-ring Replace gasket/o-rings using: O-ring Repair Kit D510001 Exhaust leaks Main seal or o-ring damaged, debris in tool. Replace gasket/o-rings using: O-ring Repair Kit D510001 Air leaks around nose when Damaged or worn o-rings Replace gasket/o-rings using: O-ring Repair Kit D510001 tool is at rest. (Driver blade in up position) Air leaks around nose when tool is in actuated position. (Driver blade in Damaged or worn bumper Replace bumper using: Brad Nailer Bumper Kit D510003 down position) Tool does not cycle in cold weather Tool not receiving air Check air supply Valve may be frozen Warm up tool Damaged or worn o-rings Replace gasket/o-rings using: O-ring Repair Kit D510001 Broken or damaged driver blade Replace Driver Blade Kit for Brad Nailer D512362 Lack of power; sluggish Low air pressure Check air supply Lack of lubrication Lubricate tool using approved pneumatic tool oil. Damaged or worn o-rings Replace gasket/o-rings using: O-ring Repair Kit D510001 Exhaust port blocked or clogged Disconnect air, remove exhaust plate from top of tool, clean port Skipping nails; intermittent feed Air restricted Check air supply and couplers Lack of lubrication Lubricate tool using approved pneumatic tool oil Nose piece screws loose Tighten nosepiece screws using appropriate Allen wrench Wrong size/angle fasteners Use only recommended fasteners Dirty magazine Clean magazine track and nosepiece Worn magazine Replace magazine Broken or damaged driver blade Replace Driver Blade Kit for Brad Nailer D512362 Trigger valve o-ring worn or damaged Replace valve using: Trigger Valve Kit D510005 Worn piston o-ring Replace piston o-ring using: O-Ring Repair Kit D510001 Worn or damaged pusher spring Replace spring Magazine loose Check that magazine latch is holding firmly Fasteners jam in tool Driver channel in nose piece worn Replace nosepiece Wrong size/ angle fasteners Use only recommended fasteners Magazine loose Check that magazine screws are holding firmly Worn driver blade Replace Driver Blade Kit for Brad Nailer D512362 Nose piece screws loose Tighten nosepiece screws using appropriate Allen wrench Nails not feeding properly Ensure nails are feeding properly into nose. D51238 Cat. # D510005 D512381 D512381 D512381 D512383 D512381 D512382 D512381 D512382 D510005 D512381 D512382