Dewalt DCF899HP2 Instruction Manual - Page 2

Installing and Removing the Battery Pack Fig. 5 - lowes

|

View all Dewalt DCF899HP2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

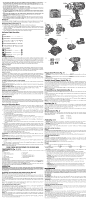

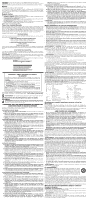

• Do not place any object on top of the charger or place the charger on a soft surface that might block the ventilation slots and result in excessive internal heat. Place the charger in a position away from any heat source. The charger is ventilated through slots in the top and the bottom of the housing. FIG. 1 DCF899 • Do not operate the charger with a damaged cord or plug. • Do not operate the charger if it has received a sharp blow, been dropped or otherwise damaged in any way. Take it to an authorized service center. • Do not disassemble the charger; take it to an authorized service center when service or repair is required. Incorrect reassembly may result in a risk of electric shock, electrocution or fire. • Disconnect the charger from the outlet before attempting any cleaning. This will reduce the risk of electric shock. Removing the battery pack will not reduce this risk. • NEVER attempt to connect two chargers together. C B A D J • The charger is designed to operate on standard 120 volt household electrical power. Do not attempt to use it on any other voltage. This does not apply to the vehicular charger. G Chargers Your tool uses a DEWALT charger. Be sure to read all safety instructions before using your charger. E Consult the chart at the end of this manual for compatibility of chargers and battery packs. Charging Procedure (Fig. 4) 1. Plug the charger into an appropriate outlet before inserting the battery pack. FIG. 2 FIG. 3 C C F 2. Insert the battery pack (F) into the charger, as shown in Figure 4, making sure the pack is fully seated in charger. The red (charging) light will blink continuously, indicating that the charging process has started. 3. The completion of charge will be indicated by the red light remaining ON continuously. The pack is fully charged and may be used at this time or left in the charger. Indicator Light Operation DCB101 PACK CHARGING H DCF899 I DCF899H PACK CHARGED FIG. 4 F FIG. 5 HOT/COLD DELAY F x PROBLEM PACK OR CHARGER E PROBLEM POWERLINE DCB107, DCB112 PACK CHARGING PACK CHARGED HOT/COLD DELAY Charge Indicators This charger is designed to detect certain problems that can arise. Problems are indicated by the red light flashing at a fast rate. If this occurs, re-insert the battery pack into the charger. If the problem persists, try a different battery pack to determine if the charger is working properly. If the new pack charges correctly, then the original pack is defective and should be returned to a service center or other collection site for recycling. If the new battery pack elicits the same trouble indication as the original, have the charger and the battery pack tested at an authorized service center. HOT/COLD DELAY DCB101 This charger has a hot/cold delay feature: when the charger detects a battery that is hot, it automatically starts a delay, suspending charging until the battery has cooled. After the battery has cooled, the charger automatically switches to the pack charging mode. This feature ensures maximum battery life. The red light flashes long, then short while in the hot/cold delay mode. DCB107, DCB112 The DCB107 and DCB112 chargers have a hot/cold delay feature. When the charger detects a battery that is hot, it automatically delays charging until the battery has cooled. When the charger detects a battery that is cold, it automatically delays charging until the battery has warmed. The red light will continue to blink, but a yellow indicator light will be illuminated during this operation. Once the battery has cooled, the yellow light will turn off and the charger will resume the charging procedure. LEAVING THE BATTERY PACK IN THE CHARGER The charger and battery pack can be left connected with the charge indicator showing Pack Charged. WEAK BATTERY PACKS: Weak batteries will continue to function but should not be expected to perform as much work. FAULTY BATTERY PACKS: This charger will not charge a faulty battery pack. The charger will indicate faulty battery pack by refusing to light or by displaying problem pack or charger. NOTE: This could also mean a problem with a charger. PROBLEM POWER LINE (DCB101) Some chargers have a Problem Powerline indicator. When the charger is used with some portable power sources such as generators or sources that convert DC to AC, the charger may temporarily suspend operation, flashing the red light with two fast blinks followed by a pause. This indicates the power source is out of limits. Wall Mounting DCB107, DCB112 These chargers are designed to be wall mountable or to sit upright on a table or work surface. If wall mounting, locate the charger within reach of an electrical outlet. Mount the charger securely using drywall screws at least 1" (25.4 mm) long, screwed into wood to an optimal depth leaving approximately 7/32" (5.5 mm) of the screw exposed. Important Charging Notes 1. Longest life and best performance can be obtained if the battery pack is charged when the air temperature is between 65 ˚F and 75 ˚F (18-24 ˚C). DO NOT charge the battery pack in air temperature below +40 ˚F (+4.5 ˚C), or above +105 ˚F (+40.5 ˚C). This is important and will prevent serious damage to the battery pack. 2. The charger and battery pack may become warm to touch while charging. This is a normal condition, and does not indicate a problem. To facilitate the cooling of the battery pack after use, avoid placing the charger or battery pack in a warm environment such as in a metal shed, or an uninsulated trailer. 3. If the battery pack does not charge properly: a. Check operation of receptacle by plugging in a lamp or other appliance; b. Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights; c. Move charger and battery pack to a location where the surrounding air temperature is approximately 65 ˚F-75 ˚F (18-24 ˚C); d. If charging problems persist, take the tool, battery pack and charger to your local service center. 4. The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the charging procedure. You may also charge a partially used pack whenever you desire with no adverse affect on the battery pack. 5. Foreign materials of a conductive nature such as, but not limited to, grinding dust, metal chips, steel wool, aluminum foil, or any buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug charger before attempting to clean. 6. Do not freeze or immerse charger in water or any other liquid. WARNING: Shock hazard. Don't allow any liquid to get inside charger. Electric shock may result. CAUTION: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling. Storage Recommendations 1. The best storage place is one that is cool and dry, away from direct sunlight and excess heat or cold. 2. For long storage, it is recommended to store a fully charged battery pack in a cool dry place out of the charger for optimal results. NOTE: Battery packs should not be stored completely depleted of charge. The battery pack will need to be recharged before use. SAVE THESE INSTRUCTIONS FOR FUTURE USE COMPONENTS (Fig. 1, 2, 3) WARNING: Never modify the power tool or any part of it. Damage or personal injury could result. A. Trigger switch F. Battery pack B. Forward/reverse button G. Worklight C. Anvil H. Detent pin (DCF899, Fig. 2) D. Main handle I. Hog ring (DCF899H, Fig. 3) E. Battery release button J. Speed selector INTENDED USE This impact wrench is designed for professional impact fastening applications. The impact function makes this tool particularly useful for driving fasteners in wood, metal and concrete. DO NOT use under wet conditions or in presence of flammable liquids or gases. This impact wrench is a professional power tool. DO NOT let children come into contact with the tool. Supervision is required when inexperienced operators use this tool. OPERATION WARNING: To reduce the risk of serious personal injury, place the forward/reverse button in the lock-off position or turn tool off and disconnect battery pack before making any adjustments or removing/installing attachments or accessories. An accidental start-up can cause injury. Installing and Removing the Battery Pack (Fig. 5) NOTE: For best results, make sure your battery pack is fully charged. To install the battery pack (F) into the tool handle, align the battery pack with the rails inside the tool's handle and slide it into the handle until the battery pack is firmly seated in the tool and ensure that it does not disengage. To remove the battery pack from the tool, press the release button (E) and firmly pull the battery pack out of the tool handle. Insert it into the charger as described in the charger section of this manual. Squeeze the tool trigger for three seconds to dissipate the slight electric charge that may still be in the tool. The worklight may come on for a brief moment. FUEL GAUGE BATTERY PACKS (FIG. 6) Some DEWALT battery packs include a fuel gauge which consists of three green LED lights that indicate the level of charge remaining in the battery pack. To actuate the fuel gauge, press and hold the fuel gauge button (K). A combination of the three green LED lights will illuminate designating the level of charge left. When the level of charge in the battery is below the usable limit, the fuel gauge will not illuminate and the battery will need to be recharged. NOTE: The fuel gauge is only an indication of the charge left on the battery pack. It does not indicate tool functionality and is subject to variation based on product components, temperature and end-user application. For more information regarding fuel gauge battery packs, please call 1-800-4-DEWALT (1-800-4339258) or visit our website www.dewalt.com. FIG. 6 K FIG. 7 D Proper Hand Position (Fig. 7) WARNING: To reduce the risk of serious personal injury, ALWAYS use proper hand position as shown. WARNING: To reduce the risk of serious personal injury, ALWAYS hold securely in anticipation of a sudden reaction. Proper hand position requires one hand on the main handle (D). Variable Speed Trigger Switch (Fig. 1) To turn the tool on, squeeze the trigger switch (A). To turn the tool off, release the trigger switch. Your tool is equipped with a brake. The anvil will stop when the trigger switch is fully released. The variable speed switch enables you to select the best speed for a particular application. The more you squeeze the trigger, the faster the tool will operate. For maximum tool life, use variable speed only for starting holes or fasteners. NOTE: Continuous use in variable speed range is not recommended. It may damage the switch and should be avoided. Forward/Reverse Control Button (Fig. 1) A forward/reverse control button (B) determines the direction of the tool and also serves as a lock-off button. To select forward rotation, release the trigger switch and depress the forward/reverse control button on the right side of the tool. To select reverse, release the trigger switch and depress the forward/reverse control button on the left side of the tool. The center position of the control button locks the tool in the OFF position. When changing the position of the control button, be sure the trigger is released. NOTE: The first time the tool is run after changing the direction of rotation, you may hear a click on start up. This is normal and does not indicate a problem. Worklight (Fig. 1) There is a worklight (G) located on the foot of the tool. The worklight is activated when the trigger switch is depressed, and will automatically turn off 20 seconds after the trigger switch is released. If the trigger switch remains depressed, the worklight will remain on. NOTE: The worklight is for lighting the immediate work surface and is not intended to be used as a flashlight. Speed Selector (Fig. 1) Your tool is equipped with a speed selector (J) which allows you to select one of three speeds. Select the speed based on the application and control the speed of the tool using the variable speed trigger switch (A). Speed 1 0-400 rpm Speed 2 0-1200 rpm Speed 3 0-1900 rpm Anvils (Fig. 2, 3) WARNING: Use only impact accessories. Non-impact accessories may break and cause a hazardous condition. Inspect accessories prior to use to ensure that it contains no cracks. CAUTION: Inspect anvils, detent pins and hog rings prior to use. Missing or damaged items should be replaced before use. Place the switch in the locked off (center) position or remove battery pack before changing accessories. ANVIL WITH DETENT PIN (FIG. 2) DCF899 To install an accessory on the anvil, align the hole in the side of the accessory with the detent pin (H) on the anvil (C). Press the accessory on until the detent pin engages in the hole. Depression of detent pin may be necessary to aid installation of accessory. To remove an accessory, depress the detent pin through the hole and pull the accessory off. ANVIL WITH HOG RING (FIG. 3) DCF899H To install an accessory on the hog ring anvil, firmly push accessory onto the anvil (C). The hog ring (I) compresses to allow the accessory to slide on. After accessory is installed, the hog ring applies pressure to help provide accessory retention. To remove an accessory, grasp the accessory and firmly pull it off. Usage Your impact tool can generate the following maximum torque: Cat # Ft.-Lbs. In.-Lbs. Nm DCF899, DCF899H 700 8400 950 CAUTION: Ensure fastener and/or system will withstand the level of torque generated by the tool. Excessive torque may cause breakage and possible personal injury. 1. Place the accessory on the fastener head. Keep the tool pointed straight at the fastener. 2. Press switch to start operation. Release switch to stop operation. Always check torque with a torque wrench, as the fastening torque is affected by many factors including the following: • Voltage: Low voltage, due to a nearly discharged battery, will reduce fastening torque. • Accessory size: Failure to use the correct accessory size will cause a reduction in fastening torque. • Bolt size: Larger bolt diameters generally require higher fastening torque. Fastening torque will also vary according to length, grade, and torque coefficient. • Bolt: Ensure that all threads are free of rust and other debris to allow proper fastening torque. • Material: The type of material and surface finish of the material will affect fastening torque. • Fastening time: Longer fastening time results in increased fastening torque. Using a longer fastening time than recommended could cause the fasteners to be overstressed, stripped or damaged. MAINTENANCE WARNING: To reduce the risk of serious personal injury, place the forward/reverse button in the lock-off position or turn tool off and disconnect battery pack before making any adjustments or removing/installing attachments or accessories. An accidental start-up can cause injury. Cleaning WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing this. WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid. CHARGER CLEANING INSTRUCTIONS WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft non-metallic brush. Do not use water or any cleaning solutions. Accessories WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT recommended accessories should be used with this product. Recommended accessories for use with your tool are available at extra cost from your local service center. If you need any assistance in locating any accessory, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website: www.dewalt.com.