Dewalt DWE357 Instruction Manual - Page 2

Cutting with Blade in Horizontal Position Fig. 5 - saw

|

View all Dewalt DWE357 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

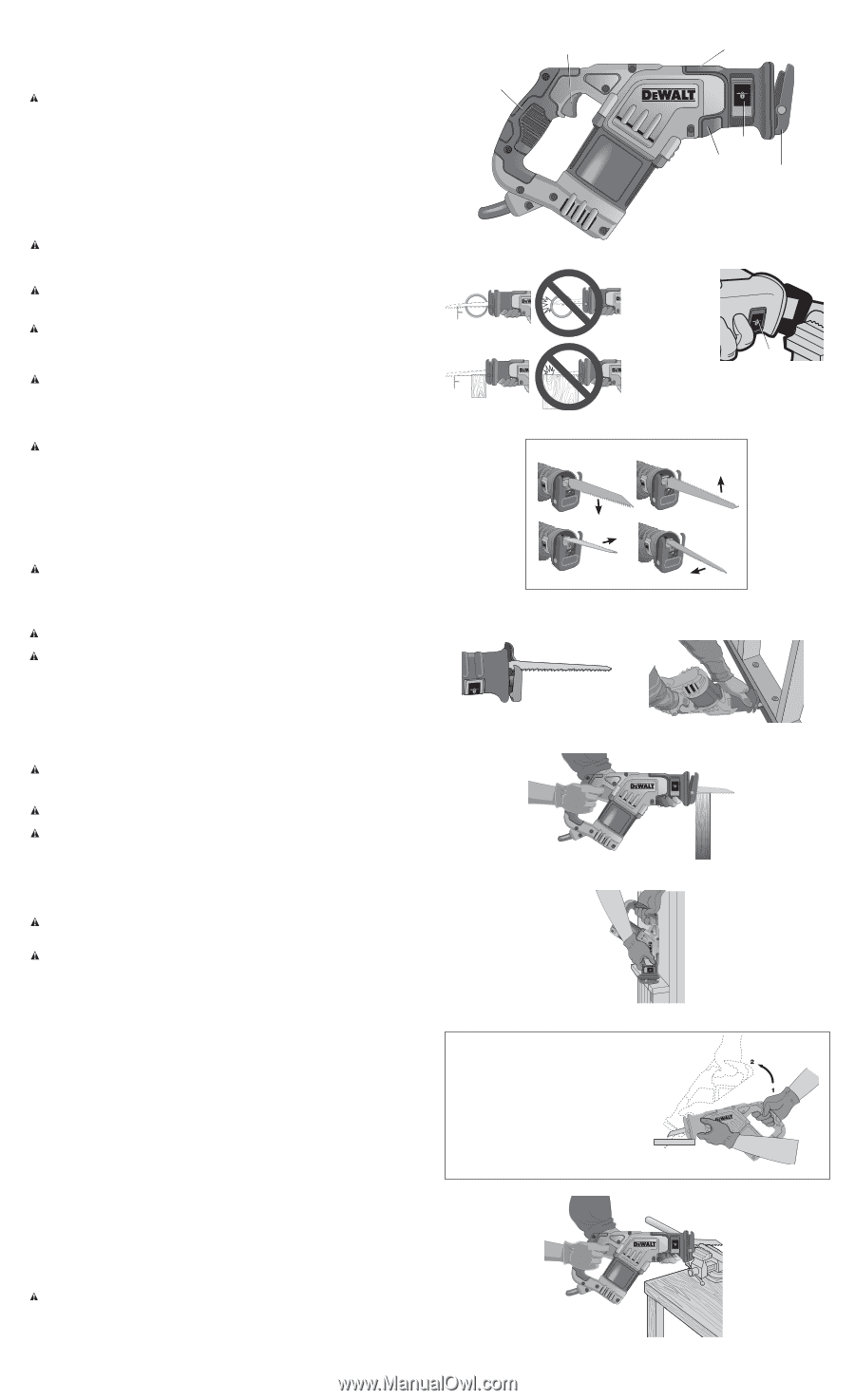

Motor Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than 10% will cause loss of power and overheating. DEWALT tools are factory tested; if this tool does not operate, check power supply. COMPONENTS (Fig. 1) WARNING: Never modify the power tool or any part of it. Damage or personal injury could result. A. Trigger switch D. Shoe B. Main handle E. Hand grip C. Blade clamp release lever INTENDED USE This compact variable speed reciprocating saw is designed for professional cutting of wood, metal, plastic and drywall. DO NOT use under wet conditions or in presence of flammable liquids or gases. This reciprocating saw is a professional power tool. DO NOT let children come into contact with the tool. Supervision is required when inexperienced operators use this tool. Variable Speed Trigger Switch (Fig. 1) WARNING: This tool has no provision to lock the switch in the ON position, and should never be locked ON by any other means. The variable speed trigger switch (A) will give you added versatility. The further the trigger is depressed the higher the speed of the saw. CAUTION: Use of very slow speed is recommended only for beginning a cut. Prolonged use at very slow speed may damage your saw. OPERATION WARNING: To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start-up can cause injury. Blade Installation and Removal (Fig. 2-4, 7) WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories. An accidental start-up can cause injury. Different blade lengths are available. Use the appropriate blade for the application. The blade should be longer than 3-1/2" (89 mm) and should extend past the shoe and the thickness of the workpiece during the cut. Do not use jigsaw blades with this tool. WARNING: Cut hazard. Blade breakage may occur if the blade does not extend past the shoe and the workpiece during the cut (Fig. 2). Increased risk of personal injury, as well as damage to the shoe and workpiece may result. TO INSTALL BLADE INTO SAW 1. Pull blade clamp release lever (C) up (Fig. 3). 2. Insert blade shank from the front. 3. Push blade clamp release lever down. NOTE: The blade can be installed in four positions as shown in Figure 4. The blade can be installed upside-down to assist in flush-to cutting as shown in Figure 7. TO REMOVE BLADE FROM SAW CAUTION: Burn hazard. Do not touch the the blade immediately after use. Contact with the blade may result in personal injury. 1. Open up blade clamp release lever. 2. Remove blade. Proper Hand Position (Fig. 1, 5-9) WARNING: To reduce the risk of serious personal injury, ALWAYS use proper hand position as shown. WARNING: To reduce the risk of serious personal injury, ALWAYS hold securely in anticipation of a sudden reaction. Proper hand position requires one hand on the main handle (B), with the other hand on the hand grip (E). Cutting with Blade in Horizontal Position (Fig. 5) Your DWE357 is equipped with a horizontal blade clamp. Installing a blade in the horizontal orientation allows cutting close to floors, walls or ceilings where limited clearance is available. Ensure that the shoe is pressed against the framing to avoid kickback. Shoe CAUTION: Cut hazard. To prevent loss of control, never use tool without shoe. The DWE357 comes with a fixed shoe that is not adjustable. Cutting (Fig. 5-9) WARNING: Always use eye protection. All users and bystanders must wear eye protection that conforms to ANSI Z87.1. WARNING: Exercise extra caution when cutting towards operator. Always hold saw firmly with both hands while cutting. Before cutting any type of material, be sure it is firmly anchored or clamped to prevent slipping. Place blade lightly against work to be cut, switch on saw motor and allow it to obtain maximum speed before applying pressure. Whenever possible, the saw shoe must be held firmly against the material being cut (Fig. 6). This will prevent the saw from jumping or vibrating and minimize blade breakage. Any cuts which put pressure on the blade such as angle or scroll cuts increase potential for vibration, kickback, and blade breakage. WARNING: Use extra caution when cutting overhead and pay particular attention to overhead wires which may be hidden from view. Anticipate the path of falling branches and debris ahead of time. WARNING: Inspect work site for hidden gas pipes, water pipes or electrical wires before making blind or plunge cuts. Failure to do so may result in explosion, property damage, electric shock, and/or serious personal injury. FLUSH-TO CUTTING (FIG. 7) The compact design of the saw motor housing and spindle housing permits extremely close cutting to floors, corners and other difficult areas. POCKET/PLUNGE CUTTING - WOOD ONLY (FIG. 8) The initial step in pocket cutting is to measure the surface area to be cut and mark clearly with a pencil, chalk or scriber. Use the appropriate blade for the application. The blade should be longer than 3-1/2" (89 mm) and should extend past the shoe and the thickness of the workpiece during the cut. Insert blade in blade clamp. Next, tip the saw backward until the back edge of the shoe is resting on the work surface and the blade clears the work surface (position 1, Fig. 8). Now switch motor on, and allow saw to come up to speed. Grip saw firmly with both hands and begin a slow, deliberate upward swing with the handle of the saw, keeping the bottom of the shoe firmly in contact with the workpiece (position 2, Fig. 8). Blade will begin to feed into material. Always be sure blade is completely through material before continuing with pocket cut. NOTE: In areas where blade visibility is limited, use the edge of the saw shoe as a guide. Lines for any given cut should be extended beyond edge of cut to be made. METAL CUTTING (FIG. 9) Your saw has different metal cutting capacities depending upon type of blade used and the metal to be cut. Use a finer blade for ferrous metals and a coarse blade for non-ferrous materials. In thin gauge sheet metals it is best to clamp wood to both sides of sheet. This will insure a clean cut without excess vibration or tearing of metal. Always remember not to force cutting blade as this reduces blade life and causes costly blade breakage. NOTE: It is generally recommended that when cutting metals you should spread a thin film of oil or other lubricant along the line ahead of the saw cut for easier operation and longer blade life. MAINTENANCE WARNING: To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start-up can cause injury. FIG. 1 A B FIG. 2 FIG. 4 FIG 5 FIG. 6 FIG. 7 FIG. 8 1. STARTING POSITION FOR POCKET CUTTING 2. ROCK TOOL UP TO NORMAL CUTTING POSITION AFTER BLADE HAS CUT THROUGH MATERIAL. 1. POSITION DE DÉPART POUR COUPE INTERNE 2. PIVOTER L'OUTIL EN POSITION NORMALE DE COUPE UNE FOIS QUE LA LAME A TRAVERSÉ LE MATÉRIAU. 1. POSICIÓN INICIAL PARA CORTES CENTRALES 2. BALANCEE LA HERRAMIENTA HACIA ARRIBA HASTA ALCANZAR LA POSICIÓN NORMAL DE CORTE LUEGO DE QUE LA HOJA ATRAVIESE EL MATERIAL. FIG. 9 E C E D FIG. 3 C