Dewalt DXGN010WK Instruction Manual - Page 17

Spark Arrester, Dxgn4500, Dxgn6000, And Dxgn7200, Dxgn14000, Fault Finding Guide

|

View all Dewalt DXGN010WK manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

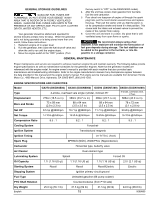

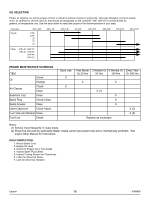

SPARK ARRESTER The spark arrester must be serviced every 100 hours to keep it functioning as designed. If the engine has been running, the muffler will be hot. Allow it to cool before servicing the spark arrester. DXGN4500, DXGN6000, and DXGN7200 Clean and inspect the spark arrester as follows: 1. Remove the four screws (B) and spark arrester screen (A) from the muffler. 2. Use a brush to remove carbon deposits from the spark arrester screen. Be careful to avoid damaging the screen. 3. The spark arrester must be free of breaks and holes. Replace the spark arrester if it is damaged. 4. Attach the spark arresting screen (A) to the muffler by aligning the holes in the screen with the holes pierced in the muffler. Thread the four screws (B) into the holes and tighten securely. DXGN14000 See instructions supplied with Spark Arrestor Kit. FAULT FINDING GUIDE SYMPTOMS ENGINE WILL NOT START NO POWER OUTPUT NOISY MACHINE OVERHEATING CIRCUIT BREAKER TRIPS English PROBABLE CAUSES 1. Oil level too low. 2. No fuel or valve(s) turned off. 3. Start switch turned Off. 4. Blocked or leaking fuel system. 5. Clogged air filter. 6. Genset under load at start-up. 1. Circuit breaker tripped. 2. GFCI receptacle tripped. 3. Faulty circuit breaker. 4. Faulty receptacle. 5. Faulty capacitor in alternator. 6. Faulty diodes in alternator. 7. Failure in alternator windings. 1. Damaged bearing. 2. Damaged exhaust system. 3. Loose or rattling parts. 1. Ventilation openings blocked. 2. Overload. 3. Ambient temperature too high. 1. Overloaded circuit. 2. Faulty equipment or cable. 3. Faulty circuit breaker. 17 CORRECTION 1. Add oil. 2. Add fuel and/or turn valve(s) on. 3. Turn switch On. 4. Repair fuel system. 5. Clean or replace air filter. 6. Disconnect load. 1. Reset circuit breaker. 2. Reset GFCI receptacle. 3. Replace circuit breaker. 4. Replace receptacle. 5. Replace capacitor. 6. Replace diodes. 7. Repair or replace alternator. 1. Replace bearing. 2. Repair or replace. 3. Repair loose or rattling parts. 1. Clear ventilation openings. 2. Verify load levels. 3. Provide better ventilation for cooling. 1. Reduce load. 2. Check, repair or replace. 3. Replace circuit breaker. 0068660