Epson LQ 1050 Product Information Guide - Page 2

LQ - 850/950/1050 DOT - MATRIX PRINTER, Printing on Special Paper, Setting the DIP Switches,

|

View all Epson LQ 1050 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

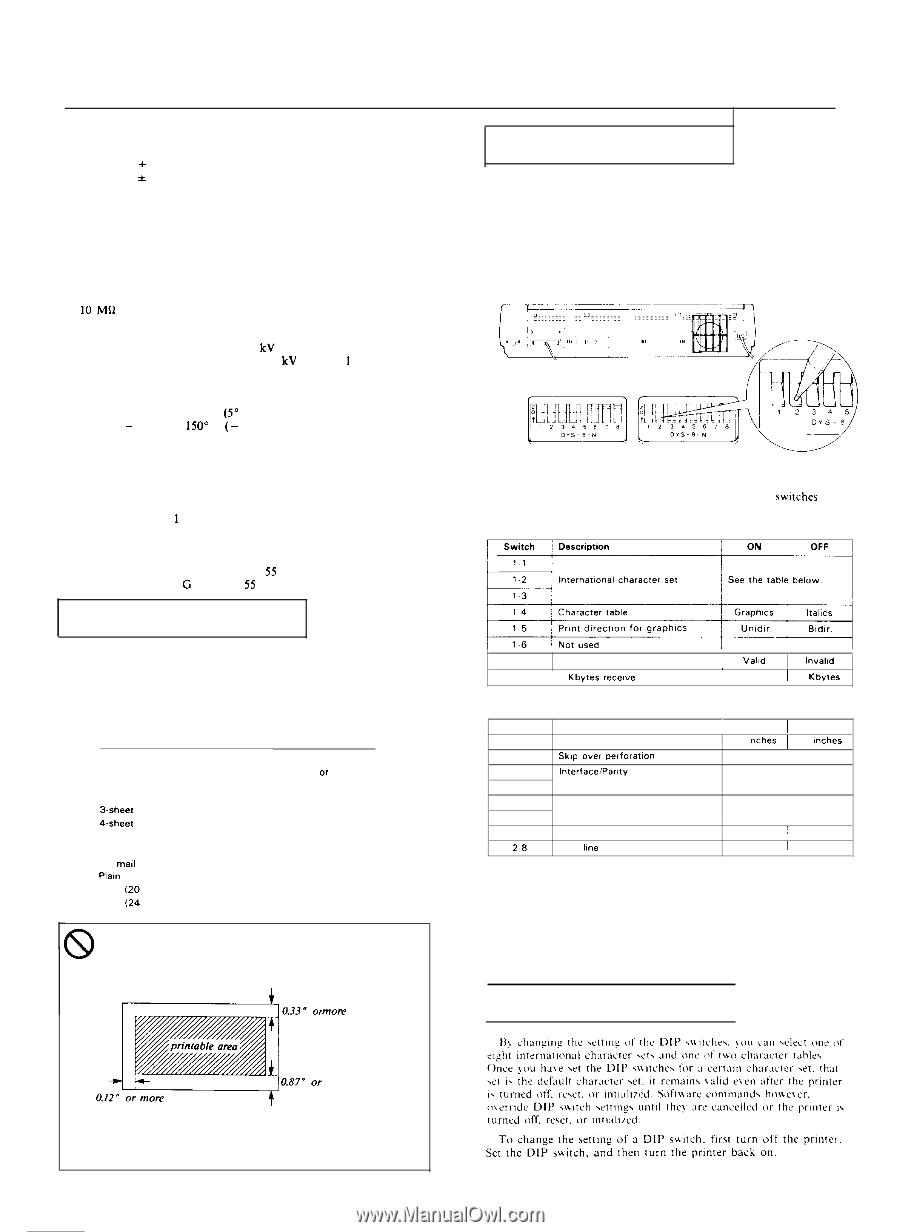

LQ - 850/950/1050 DOT - MATRIX PRINTER Electrical Voltage 120 VAC, + 10% (USA) 220 VAC, f 10% (Europe) Non-switchable Power consumption 120 Watts maximum Frequency 49.5 to 60.5 Hz Insulation resistance 10 MR between AC power line and chassis Dielectric strength 120 V model can withstand 1.25 kV rms applied between AC line and chassis for 1 minute, or 1.5 kV rms for 1 second Environment Temperature Operation: 41" F to 95" F (5" C to 35" C) Storage: - 22" F to 150" F (- 30" C to 65" C) Humidity Operation: 10% to 80% without condensation Storage: 5% to 85% without condensation Shock Operation: Up to 1 G within 1ms Storage: Up to 2 G within 1ms Vibration Operation: Up to 0.25 G at up to 55 Hz Storage: Up to 0.5 Cl at up to 55 Hz Printing on Special Paper For printing on special types of paper, see the table below. When the paper thickness lever is set to position 4 or higher, the MULTIPART light comes on and the printing speed is reduced. The following table gives you general guidelines for selecting the right paper thickness lever position to match your paper: Paper Type Lever Position Paper (single sheets or continuous) Thin paper Multi-part paper P-sheet 3sheet 4-sheet Labels Envelopes Air mall PIaWl Bond I20 lb.1 Bond (24 lb.1 2 2 or 1 3 4 5 4 4 4 or 5 6 6 7 When printing on envelopes, be sure that your application 8 program settings keep the printing entirely within the printable area of the envelopes as shown below. more Setting the DIP Switches By adjusting the settings of the two groups of DIP switches (SW1 and SW2) in the back of the printer, you can control various features such as character set and page length. To change the setting of a DIP switch, first turn off the printer. Using a pencil, pen, or other pointed instrument, change the setting as shown below. Then, turn the printer back on. SW 1 SW 2 The tables below describe the functions of the DIP switches DIP Switch 1 1 7 1.8 Cut sheet feeder mode I 6 Kbytes recenve buffer i Valid lnvalld 1 0 bytes 1 6 Kbytes DIP Switch 2 Switch Description 21 Page length 22 Skip over perforation 23 InterfaCeiParlty 2-4 25 Baud rate 26 27 Short tear-off mode 28 Auto kne feed / ON 1 OFF I 12 Inches 1 11 Inches ON I OFF See the table below See the table below ON : OFF ON 1 OFF represents the DIP switch settings that have been preset at the factory. The factory settings for International character sets (DIP switches 1-1 to 1-3), the Character table (DIP switch 1-4). and Page length (DIP switch 2-1) vary depending on the country, and are not shown in the tables above. Selecting Character Sets more To make sure that the printing fits within this area, always perform a sample printing test using a normal single sheet of paper before printing on envelopes. LQ - 850/950/1050 - 2 12/12/88 24 - Pin Printers