Epson Stylus CX3200 Technical Brief (Ink Jet Printers) - Page 2

Epson MicroPiezo Technology:, High Print Resolution:, Small ink droplet size:, Thermal technologies - printer

|

View all Epson Stylus CX3200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

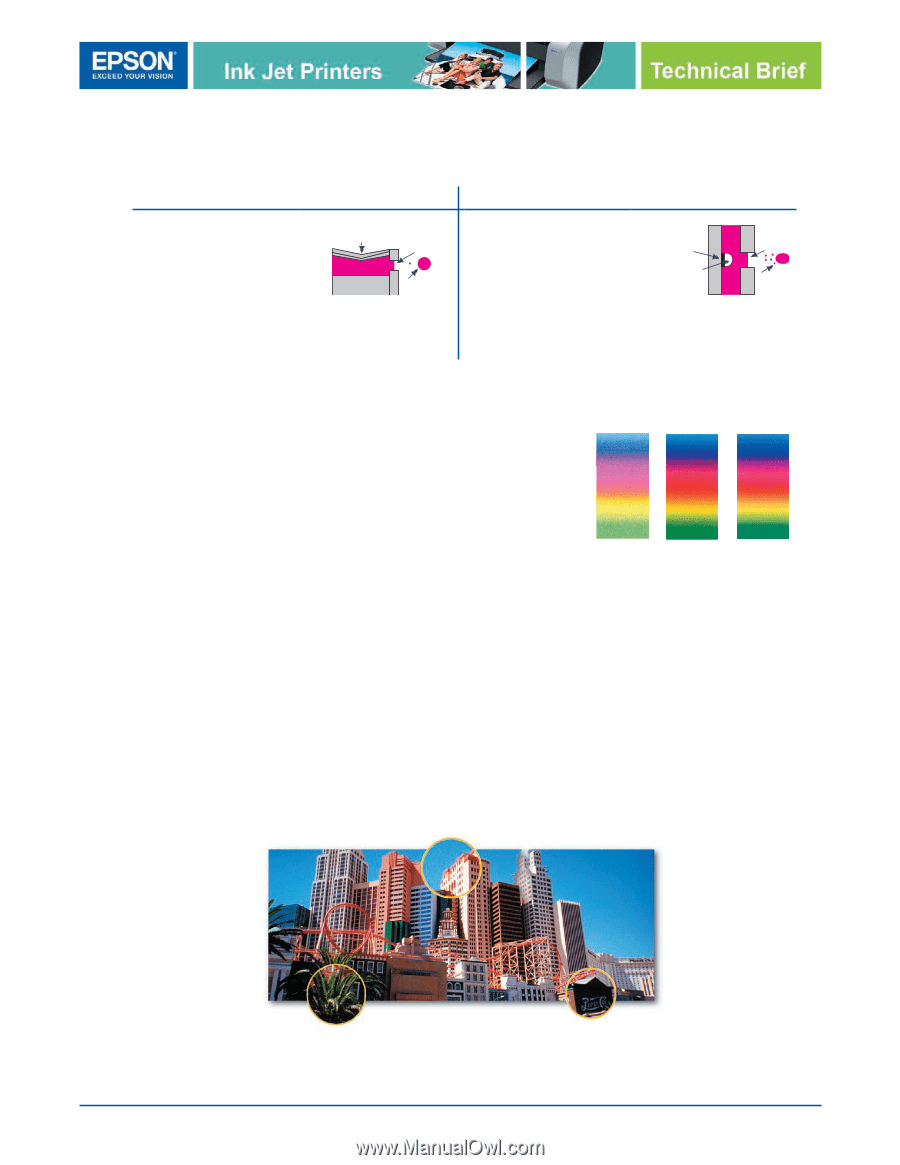

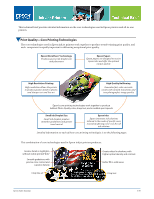

1. Epson MicroPiezo Technology: Epson Micro Piezo print heads use high-precision mechanical pumps to produce ink droplets, and no heat is involved in printing. Here's how it compares to thermal ink jet technology, used in other ink jet printers: Epson MicroPiezo Technology Mechanical method: Precise electrical pulses cause the ink reservoir wall to deflect inward, projecting ink through the nozzle. Piezo Crystal Deformation Nozzle Ink Droplet Epson's MicroPiezo technology results in consistent ink droplets without satellites (unwanted ink spray) or misting. Thermal technologies Heat method: Heat produces a vapor bubble in the ink reservoir which expands and is ejected through the nozzle. Resistor Ink Bubble Nozzle Droplet Some thermal printers produce more inconsistent droplets with satellites and misting. 2. High Print Resolution: Resolution, which is generally measured in dots per inch (DPI) is an important factor in achieving print quality. Epson printers are unique in combining very small, variable-size ink droplet sizes with high resolutions to precisely print crisp details in photos and laser sharp text. Also, Epson's variable ink droplet sizes and high resolutions combine to improve color ranges and accuracy because Epson printers can use halftone algorithms with more color combinations and smoother color gradations. Effect of Print Resolution and Small, Variable-Size Ink Droplets 3. Small ink droplet size: Most Epson printers produce ink droplets so small you cannot see them with the naked eye. A smaller ink droplet allows the printer to produce a greater number of different colored "printed dots" because a wider range of tiny droplets can be combined to create a larger color palette. Additionally, smaller ink droplets produce less visible printed dots, especially apparent in the lightest areas of a photograph. Gradations and blends become smoother as resolution and droplet control are increased Epson printers use Variable Size Droplet Technology, where the printers can produce a number of different ink droplet sizes. The size and number of droplets varies by model, but offers these benefits: • Different ink droplet sizes can be combined to achieve more tone representations • The smallest ink droplets can be used in the low-density or highlight areas, reducing the visibility of printed "dots" • Large ink droplets are used in dense coverage areas to improve print speed With this technique, Epson printers can produce high print quality without sacrificing print speed and without having to increase the number of nozzles on the print head. Smallest ink droplets produce smooth photos, especially beneficial for highlights and detailed areas Variable sizes combine to achieve more tone representations for smoother gradations Ink Jet Printer Technical Brief Large droplets are used in dense coverage areas allowing Epson to have fast print speeds without increasing the number of print head nozzles Page 2