GE PGP990SENSS Use and Care Manual - Page 22

Gas And Electrical Location, Preparing The Countertop, Provide Adequate, Gas Supply, Pressure - dimensions

|

UPC - 084691171089

View all GE PGP990SENSS manuals

Add to My Manuals

Save this manual to your list of manuals |

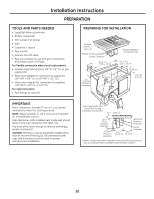

Page 22 highlights

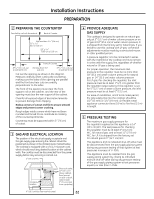

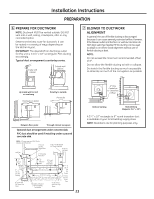

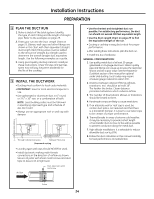

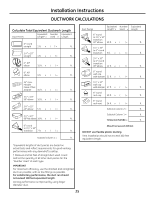

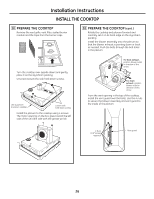

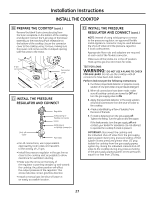

Installation Instructions PREPARATION 2 PREPARING THE COUNTERTOP Countertop cut-out dimensions Back of Counter Not less than 15⁄ 16″ (2.4 cm) 21″ ± 1⁄ 16″ 53.5 ± 0.16 cm 29″ ± 1⁄ 16″ 73.66 cm ± 0.16 cm Front of Counter 813⁄ 16″ min. cut-out to wall (22.2 cm) Not less than 17⁄ 8″ (4.8 cm) 813⁄ 16″ min. cut-out to wall (22.2 cm) Cut out the opening as shown in the diagram. Measure carefully when cutting the countertop, making sure the sides of the opening are parallel and the front and rear cuts are exactly perpendicular to the sides. The front of the opening must clear the front support rail on the cabinet, and the rear of the opening must clear the rear support of the cabinet. Chamfer all exposed edges of decorative laminate to prevent damage from chipping. Radius corners of cutout and file to ensure smooth edges and prevent corner cracking. Rough edges inside corners which have not been rounded and forced fit can contribute to cracking of the countertop laminate. Countertop must be supported within 3″ (7.6 cm) of cutout. 3 GAS AND ELECTRICAL LOCATION The position of the electrical supply receptacle and the gas supply pipe entering the cabinet should be positioned as shown in the shaded areas marked below. The cooktop is equipped with a 4 ft (1.2 m) power cord, which should reach any desired location on the cabinet walls. The cooktop must be disconnected from the power supply before any servicing is carried out. 3″ (7.6 cm) Min. Gas pipe location Electrical outlet 12″ (30.5 cm) above cabinet floor (mount on side or back cabinet wall 3″ [7.6 cm] min. from centerline) 4 PROVIDE ADEQUATE GAS SUPPLY This cooktop is designed to operate on natural gas only at 5″ (12.7 cm) of water column pressure or on LP gas at 10″ (25.4 cm) of water column pressure. It is shipped from the factory set for natural gas. If you decide to use this cooktop with LP gas, conversion adjustments must be made by a service technician or other qualified person. A pressure regulator is to be connected in series with the manifold of the cooktop and must remain in series with the supply line, regardless of whether natural or LP gas is being used. For proper operation, the maximum inlet pressure to the regulator must be no more than 10″ (25.4 cm) water column pressure for natural gas, or 14″ (35.5 cm) water column pressure for LP gas. For checking the regulator, the inlet pressure must be at least 1″ (2.5 cm) greater than the regulator output setting. If the regulator is set for 5″ (12.7 cm) of water column pressure, the inlet pressure must be at least 6″ (15.2 cm). For ease of installation, and if local codes permit, the gas supply line into the cooktop should be 1/2″ (13 mm) or 3/4″ (19 mm) I.D. flexible metal appliance connector three (0.9 m) to five feet (1.5 m) in length. 5 PRESSURE TESTING The maximum gas supply pressure for the regulator supplied on this appliance is 14″ (35.5 cm) W.C. The test pressure for checking this regulator must be at least 6″ (15.2 cm) W.C. for natural gas, and at least 11″ (27.9 cm) W.C. for LP. It is shipped from the factory set for natural gas at 5″ (12.7 cm) W.C. This appliance and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1⁄2 PSIG. This appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1⁄2 PSIG. 4″ (10.2 cm) (to clear toe kick area) 22