Hayward Perflex Perflex EC50 - Page 3

Perflex Specifications, Parts - Model Ec50 Filter - pool filter parts

|

View all Hayward Perflex manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

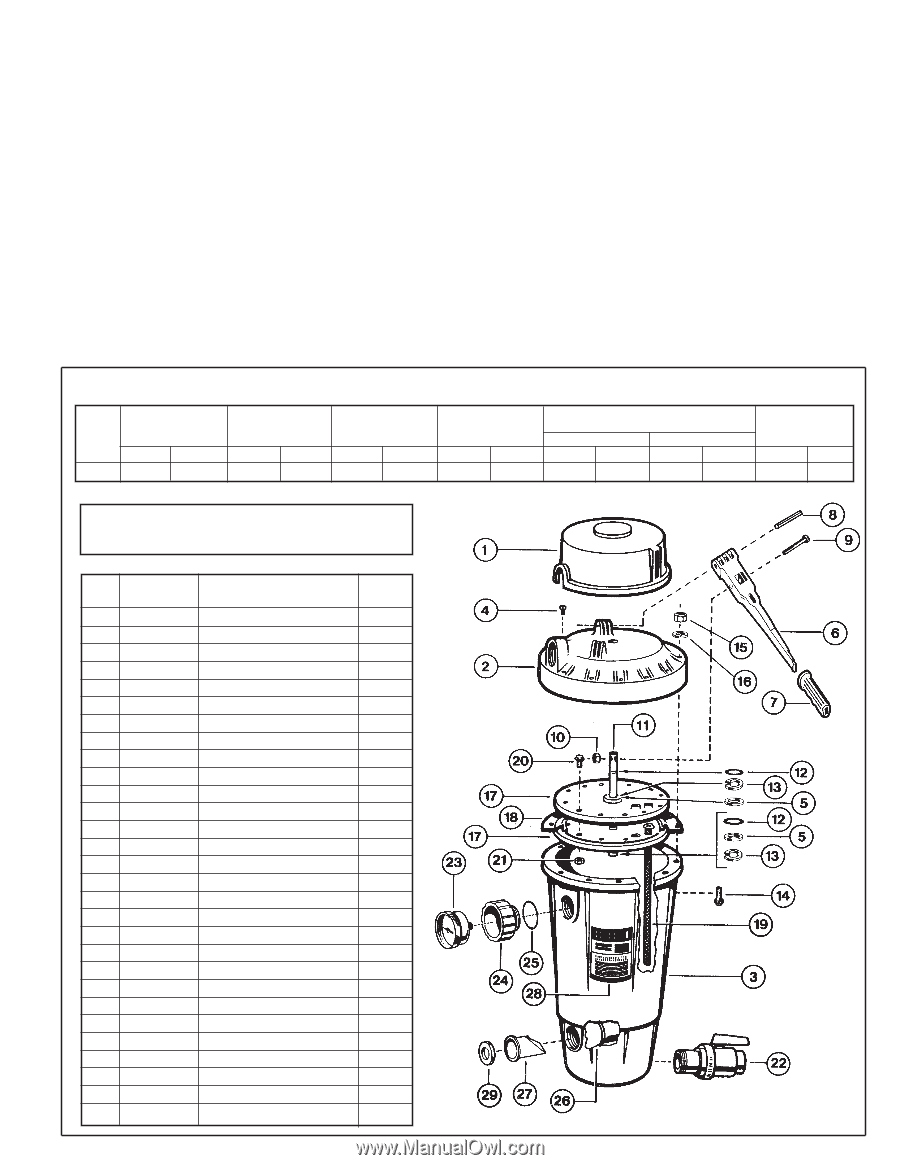

GAUGE/INSPECTION PORT ADAPTER The gauge/inspection port adapter provides an easy way to look into the filter at the "top" area of the tube nest assembly. It gives a quick inspection capability to check tube nest condition (algae, calcium or D.E. build-up, etc.) without requiring removal of the filter head. It also allows you to wash off trapped debris and excess D.E. from between the Flex-Tubes and from under the tube sheet by spraying with a garden hose, or use Hayward's Jet-Action Cleaning Wand (EC2024) which attaches to a garden hose. To remove adapter-shut off pump and valves and drain water in filter to below port. Unscrew adapter, with gauge, counterclockwise. To reinstall-thread adapter, with O-ring in place, securely into filter housing. PREVENTIVE MAINTENANCE While Perflex filters are basically resistant to the difficulties often encountered as a result of chemical build-up in swimming pools, it is important to keep in mind that the mineral content in a pool increases every day as a result of the chemicals added and the normal water evaporation process. If the concentration of minerals is allowed to get too high, the minerals will form deposits on the Flex-Tubes inside the filter, and will eventually result in shortened filter cycles. To guard against this, a yearly chemical cleaning (soaking) of the Flex-Tube assembly is suggested. Use commercially available 20% muriatic acid added to water in 1 to 1 ratio; or use other commercial filter element cleaner mixed according to the package instructions. Use a plastic container and take extreme caution when handling cleaning agents as they can be harmful to the eyes, skin and clothing. After cleaning, thoroughly flush all affected parts with cold water. MODEL NO. EC50 EFFECTIVE FILTRATION RATE FT2 M2 25 2.33 DESIGN FLOW RATE GPM LPM 50 189 PERFLEX SPECIFICATIONS PRESSURE LOSS AT DESIGN FLOW RATE PSI BAR 1 0.07 MAXIMUM WORKING PRESSURE PSI BAR 50 3.45 REQUIRED CLEARANCE SIDE ABOVE IN MM IN MM 6 152 10 254 RECOMMENDED AMOUNT OF D.E. LBS KGS 5 2.3 PARTS - MODEL EC50 FILTER REF. NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 PART NO. ECX11156 ECX10334 ECX11344 ECX1321A ECX1011 ECX1040 ECX1037B ECX100Z9 ECX4236 ECX4249 ECX1009 ECX9611246 ECX1014 ECX10271 ECX176855 ECX1077 ECX1004 ECX1003 ECX1032 SPX1500N1 SPX1500Y1 SP0723 ECX27091 ECX12866 ECX1287 ECX1256 ECX4077B1 ECX1028 ECX1055 DESCRIPTION Bump Mechanism Cover Filter Head w/Vent Valve Filter Body w/Flow Diffuser Vent Valve w/O-Ring Thrust Washer Bump Handle Assembly Bump Handle Grip Pivot Pin Shoulder Screw Locknut Bump Shaft O-Ring Retainer Filter Head Screw Filter Head Nut Washer Tube Sheet (Top or Bottom) Diaphragm Gasket Flex-Tube™ Assembly Tube Sheet Screw Tube Sheet Nut 1-1/2" Ball-Type Drain Valve Pressure Gauge, Back Mount Gauge/Inspection Port Adapter Adapter O-Ring Flow Diffuser w/Check Valve Check Valve Decal - Operation Flow Controller NO. REQ'D. 1 1 1 1 2 1 1 1 1 1 1 2 2 12 12 12 2 1 72 12 12 1 1 1 1 1 1 1 1