Hayward Power-Flo LX Models: SP1575LXTL SP1580TL and SP1580X15TL - Page 3

Seal Change Instructions - parts

|

View all Hayward Power-Flo LX manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

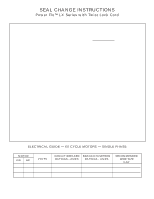

SEAL CHANGE INSTRUCTIONS Power Flo™ LX Series with Twist Lock Cord GENERAL Exercise extreme care in handling and installing the new seal and ceramic seat assembly. The lapped and polished surfaces may easily be damaged by dirt or scratching. For safety, all service must be performed with all power shut off. 1. Remove pump and motor assembly from piping system. 2. Remove pump housing cover (with strainer attached) by removing the eight (8) housing bolts and nuts which fasten housing cover to pump housing. The impeller is now exposed. 3. To remove impeller, insert screwdriver in slot at end of motor.* Hold screwdriver so as to keep shaft from turning, and rotate the impeller in a counterclockwise direction. The spring portion of the seal assembly is now exposed. 4. Note carefully the position of the spring seal and pull it off the impeller. 5. To remove the stationary (ceramic seat) part of the seal assembly: a. Loosen the four (4) motor securing bolts and disengage the motor from the pump housing. b. With motor removed, press the clear plastic and ceramic seat assembly out of the pump housing recess. If tight, tap lightly from the "motor" side. 6. Clean and lubricate the impeller hub shaft and pump housing seal recess with a dilute solution of non-granulated liquid-type soap. The use of petroleum or silicone lubricants can contribute to seal leakage. 7. Press the new spring portion of the assembly onto the impeller, black polished surface facing away from the impeller. 8. Carefully press ceramic seat, with O-ring, into clear plastic seat retainer-polished surface facing out. Be sure O-ring is in place on cut ridge of clear plastic retainer. Press plastic retainer, with ceramic seat inside, into recess of pump housing-O-ring end first. Replace the assembly firmly and evenly. 9. Carefully insert the motor shaft through the seat assembly, and secure motor to pump housing with four (4) motor securing bolts. (Be sure motor base is positioned properly.) 10. Screw the impeller, with spring seal, onto the motor shaft, hand tight, by turning clockwise. 11. Clean fiber gasket (replace if necessary) and fasten housing cover to pump housing with eight (8) bolts and nuts. Tighten bolts and nuts alternately and evenly. 12. Reconnect pump to piping system. Be sure to fill strainer with water before restarting. * For A.O. Smith Canopy Style Motors: Remove motor end cover and carefully apply wrench to flat on motor shaft to hold shaft from turning. ELECTRICAL GUIDE - 60 CYCLE MOTORS - SINGLE PHASE MOTOR KW HP .55 3/4 .75 1 1.1 1-1/2 VOLTS 115 115 115 CIRCUIT BREAKER BRANCH FUSETRON RATINGS - AMPS RATINGS - AMPS 15 15 20 20 20 20 A separate electrical circuit, utilizing a rating as above, is recommended. RECOMMENDED WIRE SIZE 0-50' #14 #12 #12