Husqvarna HU550FH Operation Manual - Page 12

Lawn Mower - carburetor

|

View all Husqvarna HU550FH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

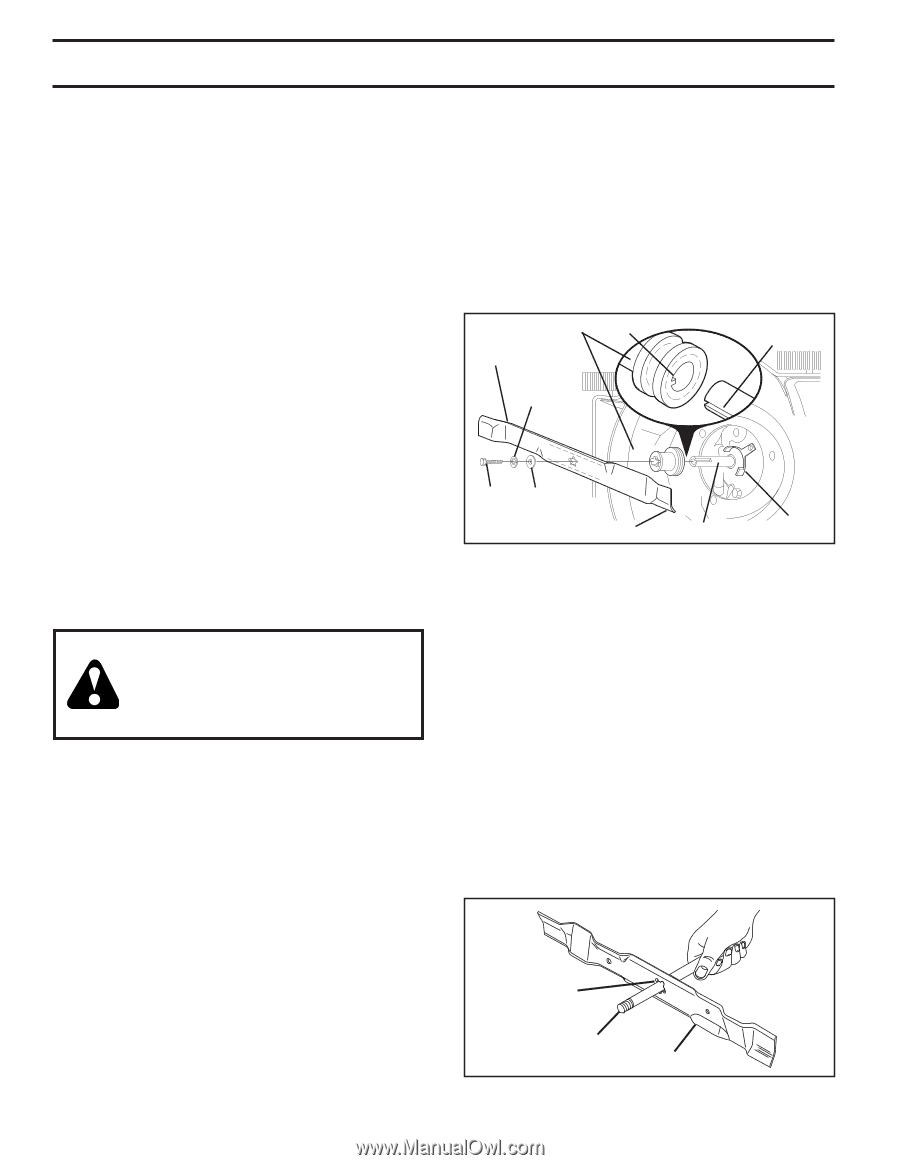

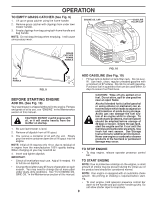

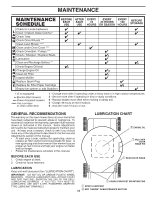

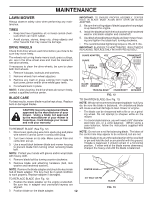

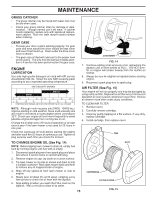

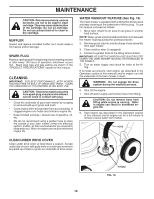

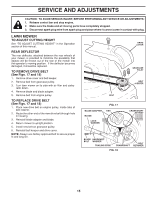

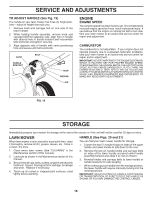

MAINTENANCE LAWN MOWER Always observe safety rules when performing any maintenance. TIRES • Keep tires free of gasoline, oil, or insect control chemicals which can harm rubber. • Avoid stumps, stones, deep ruts, sharp objects and other hazards that may cause tire damage. DRIVE WHEELS Check front drive wheels each time before you mow to be sure they move freely. The wheels not turning freely means trash, grass cuttings, etc. are in the drive wheel area and must be cleaned to free drive wheels. If necessary to clean the drive wheels, be sure to clean both front wheels. IMPORTANT: TO ENSURE PROPER ASSEMBLY, CENTER HOLE IN BLADE MUST ALIGN WITH STAR ON BLADE ADAPTER. 3. Be sure the trailing edge of blade (opposite sharp edge) is up toward the engine. 4. Install the blade bolt with the lock washer and hardened washer into blade adapter and crankshaft. 5. Use block of wood between blade and lawn mower housing and tighten the blade bolt, turning clockwise. • The recommended tightening torque is 35-40 ft. lbs. IMPORTANT: BLADE BOLT IS HEAT TREATED. IF BOLT NEEDS REPLACING, REPLACE ONLY WITH APPROVED BOLT. BLADE ADAPTER BLADE LOCK WASHER KEY CRANKSHAFT KEYWAY 1. Remove hubcaps, locknuts and washers. 2. Remove wheels from wheel adjusters. 3. Remove any trash or grass cuttings from inside the dust cover, pinion and/or drive wheel gear teeth. 4. Put wheels back in place. NOTE: If after cleaning, the drive wheels do not turn freely, contact a qualified service center. BLADE CARE For best results, mower blade must be kept sharp. Replace bent or damaged blades. CAUTION: Use only a replacement blade approved by the manufacturer of your mower. Using a blade not approved by the manufacturer of your mower is hazardous, could damage your mower and void your warranty. TO REMOVE BLADE (See Fig. 12) 1. Disconnect spark plug wire from spark plug and place wire where it cannot come in contact with plug. 2. Turn lawn mower on its side. Make sure air filter and carburetor are up. 3. Use a wood block between blade and mower housing to prevent blade from turning when removing blade bolt. BLADE HARDENED BOLT WASHER TRAILING EDGE BELT CRANKSHAFT RETAINER FIG. 12 TO SHARPEN BLADE (See Fig. 13) NOTE: We do not recommend sharpening blade - but if you do, be sure the blade is balanced. An unbalanced blade will cause eventual damage to lawn mower or engine. • The blade can be sharpened with a file or on a grinding wheel. Do not attempt to sharpen while on the mower. • To check blade balance, you will need a 5/8" diameter steel bolt, pin, or a cone balancer. (When using a cone balancer, follow the instructions supplied with balancer.) NOTE: Do not use a nail for balancing blade. The lobes of the center hole may appear to be centered, but are not. • Slide blade on to an unthreaded portion of the steel bolt or pin and hold the bolt or pin parallel with the ground. If blade is balanced, it should remain in a horizontal position. If either end of the blade moves downward, sharpen the heavy end until the blade is balanced. NOTE: Protect your hands with gloves and/or wrap blade with heavy cloth. 4. Remove blade bolt by turning counter-clockwise. 5. Remove blade and attaching hardware (bolt, lock washer and hardened washer). NOTE: Remove the blade adapter and check the key inside hub of blade adapter. The key must be in good condition to work properly. Replace adapter if damaged. CENTER HOLE TO REPLACE BLADE (See Fig. 12) 1. Position the blade adapter on the engine crankshaft. Be sure key in adapter and crankshaft keyway are aligned. 5/8" BOLT OR PIN BLADE FIG. 13 2. Position blade on the blade adapter. 12