JET Tools BDB-1340A User Manual - Page 9

Lubrication, Center Back Gear Shaft

|

View all JET Tools BDB-1340A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

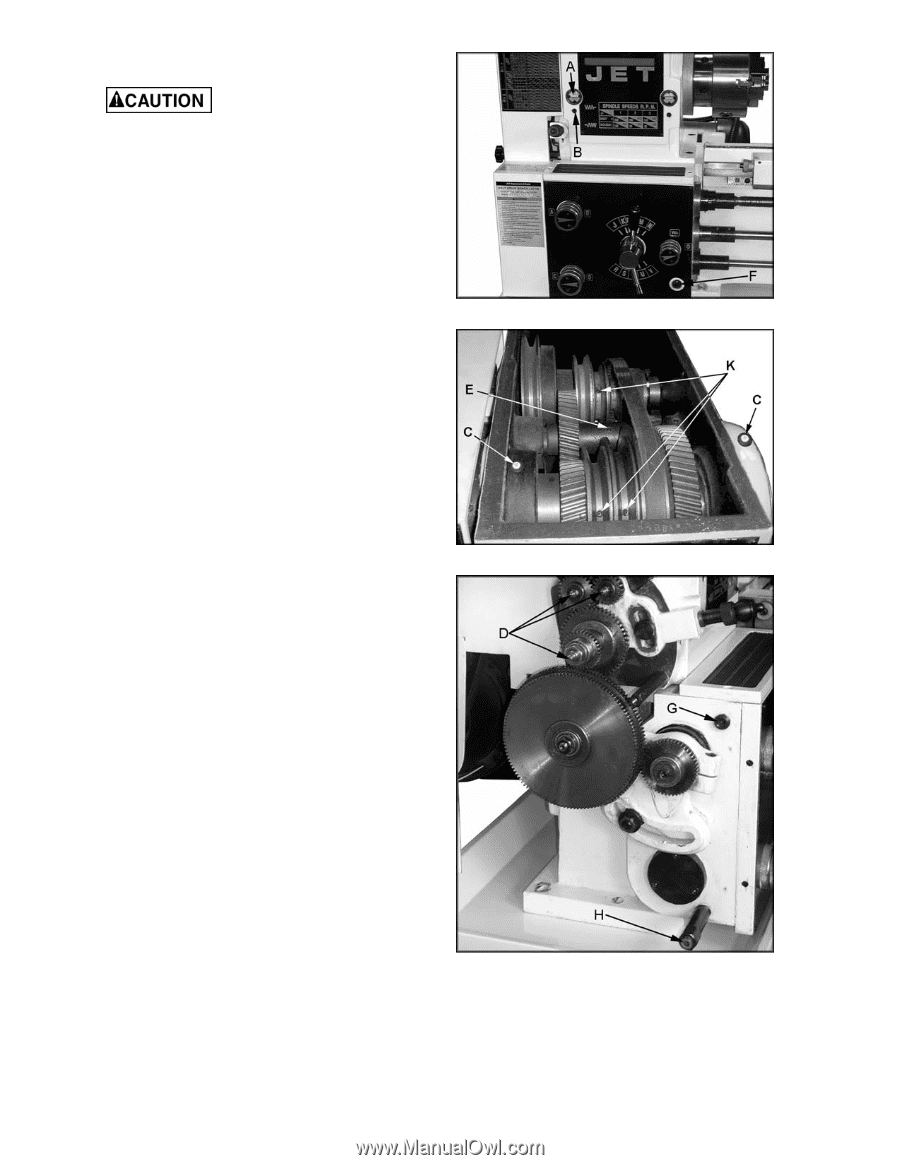

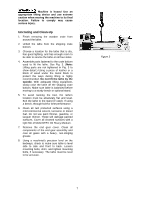

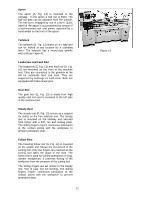

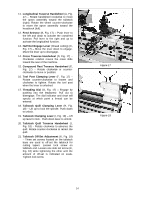

Lubrication Lathe must be serviced at all lubrication points and all reservoirs filled to operating level before the lathe is placed into service. Failure to comply may cause serious damage to the lathe. 1. Headstock - Oil must be up to indicator mark in both oil sight glasses (A, Fig. 5). Top off with Mobil DTE® Oil Heavy Medium. The headstock should be drained and refilled after the first three months of operation. Then, change oil in the headstock annually. Drain oil completely by removing drain plugs (B, Fig. 5). Also loosen the three set screws in the pulleys (K, Fig. 6) and shaft (E, Fig. 6) and drain the oil from these. When done, retighten the set screws (K,E) and re-insert the drain plugs (B). Refill by removing fill plugs (C, Fig. 6). Grease three fittings (D, Fig. 7) with Mobil 1® Synthetic Universal Grease daily. 2. External Gears - Coat all gears with a heavy, non-slinging grease, see Figure 7. 3. Center Back Gear Shaft - Remove the set screw on the shaft (E, Fig. 6) and oil with a couple of drops of Mobil DTE® Oil Heavy Medium once weekly. 4. Quick Change Gearbox - Oil must be up to indicator mark in oil sight glass (F, Fig. 5). Top off with Mobil DTE® Oil Heavy Medium. Fill by removing plug (G, Fig. 7). Drain oil by removing drain plug (H, Fig. 7) and refill after the first month of operation. Then, change oil in the gearbox annually. 9 Figure 5 Figure 6 Figure 7