Konica Minolta bizhub PRESS C71cf bizhub PRESS C71cf Safety Information Guide - Page 17

Guidelines for Safety Usage Paper Feeding/Winding

|

View all Konica Minolta bizhub PRESS C71cf manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

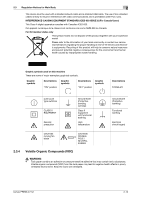

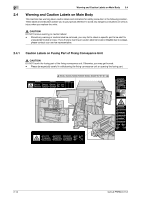

2 2.2.5 Warnings and Precautions for Roll Winder RW-101/Roll Winder RW-201 2.2 Guidelines for Safety Usage (General) If the machine is used in a wrong way, the machine may be damaged or broken, or it may lead to a physical danger to the operator. For the operator's safety, always follow the instructions described below. - Read thoroughly the instructions about safety and warnings. - Check that no one is around in dangerous areas before operating the machine. - Never remove or disable safety covers or safety limit switches. - Do not clean, maintain, or repair the machine while the machine is operating. Always stop the machine and turn off the main power supply before each of the operations. - Do not insert your hands in the machine while the machine is operating. (ex: removing samples) - Always turn off the main power supply before opening the electric control panel. - The edge of a paper is dangerous not only while the machine is operating but also while the machine has stopped. Do not enter the space between the units carelessly. - Never touch the rolling roller. - If you notice any abnormal sound, vibration, or abnormal odor, immediately stop the machine. 2.2.6 Guidelines for Safety Usage (Paper Feeding/Winding) When feeding or replacing a paper roll, always follow the instructions described below. - Always stop the machine before feeding or replacing a paper roll with a new one. - Stop the machine before installing or removing paper holding bars. - Always stop the machine before moving or adjusting each part. - When you open or close a cover, be careful not to get your hand or arm caught in or not to collide with it. Special attention should be paid to the location with a caution label attached in order to avoid unexpected injury. - Be careful not to touch projections such as those of safety limit switches. Failure to do so may cause unexpected injury or malfunction. 2.2.7 Guidelines for Safety Usage (Safety and Maintenance) For safety and maintenance of the machine, always follow the instructions described below. - Do not operate a damaged machine or a machine that does not operate properly. - Always inspect the machine before operating the machine and perform periodic inspections. - Make sure that the power has been shut off before maintenance or repair works. - For the inspections that require disassembly and assembly, always contact our customer engineer or your service representative. - Never reconstruct the machine or accessories. (ex: removing safety limit switches) - When you desire any reconstruction of the machine, contact us or your service representative. We do not take any responsibility for the reconstructions we have no concern with. - Never peel off each label. If any label has been peeled off, ask us or your service representative for a new label. Certainly attach the new label at the original position. - When you open or close a cover, be careful not to get your hand or arm caught in or not to collide with it. Special attention should be paid to the location with a caution label attached in order to avoid unexpected injury. - Be careful not to touch projections such as those of safety limit switches. Failure to do so may cause unexpected injury or malfunction. 2.2.8 Inspections before Power-on Always check the following points before turning on the power of the machine. 1 Check that all the doors and caps or covers of the control panel, operation box, and relay box of the machine are closed. (Rating plates indicating the caution have been attached on them.) A high voltage may be applied to some components and parts, such as power supplies and terminals, in those panels or boxes. If you touch these parts, you may get an electrical shock. Especially, check that the door of the control panel has been closed. 2 Check that the main breaker is [OFF]. 3 Check that connectors have been plugged and inserted in the appropriate positions as well as that any wiring breakage is not present. 2-10 bizhub PRESS C71cf