Lexmark E260D Service Manual - Page 62

Messages and error codes, User attendance messages, Paper jam error codes (200-series) - driver

|

UPC - 734646084079

View all Lexmark E260D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 62 highlights

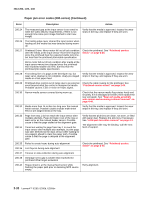

4513-200, -220, -230 Messages and error codes Note: The following message and error codes will be visible only in the print event log in the diagnostic mode for E260, E260d, and E260dn. See "Diagnostics mode selections" on page 3-8. The printer operator panel displays light patterns describing the current state of the printer and indicates possible printer problems that must be resolved. This topic provides a list of all printer messages and explains what they mean. User attendance messages Cartridge error codes Error 30 31 32 Description Invalid refill Missing or defective cartridge Unsupported cartridge Action Replace the cartridge. Paper jam error codes (200-series) Repeating jams or jam messages can be caused by any of the following: • Faulty/contaminated pick solenoids or worn cams of the solenoids. • Faulty/contaminated flags or springs. • Debris in the paper path. • Media not of the specified length. Paper jam error codes (200-series) Error Description Action 200.00 Paper jam around input sensor. Remove the PC kit and paper or debris at the input sensor. 200.01 200.02 Classic input jam. The media is too long over the input sensor. Possible causes include multi-sheet feed, tray size sensing problem, and media slippage. The main input sensor never became uncovered from the sheet ahead. First, remove the PC kit and paper or debric at the input sensor. Then, inspect the flag on the input sensor. It should rotate freely. Replace the sensor if necessary. Finally, check the paper size settings in the printer and the driver. 200.03 The video never started on the page at the input Check the printhead. See "Printhead service sensor within two inches after hitting the input sensor check" on page 2-65. 200.04 The media at the input sensor before interrupt occurred-not enough time elapsed since the printhead started to expect the printhead mirror motor lock. Possible causes include bouncy sensor or exceptionally fast pick- perhaps due to media prestaged in the source tray. Carefully remove the tray and notice if the leading edge of the media is pointed upward and out of the tray. If so, then inspect the tray wear strips and replace if necessary. Inspect the input sensor flag and replace it if it does not rotate freely or is too loose. 200.06 Imaged page not expected page (bouncy passthru sensor) Remove the toner cartridge/PC kit. At the front, remove the upper front guide, and inspect the flag on the manual input sensor. If the flag is loose, then replace it. See "Media manual input sensor removal" on page 4-39. 2-36 Lexmark™ E260, E260d, E260dn