Lowrance X-4 Pro Operation Manual - Page 21

Bracket Installation - requirements

|

View all Lowrance X-4 Pro manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

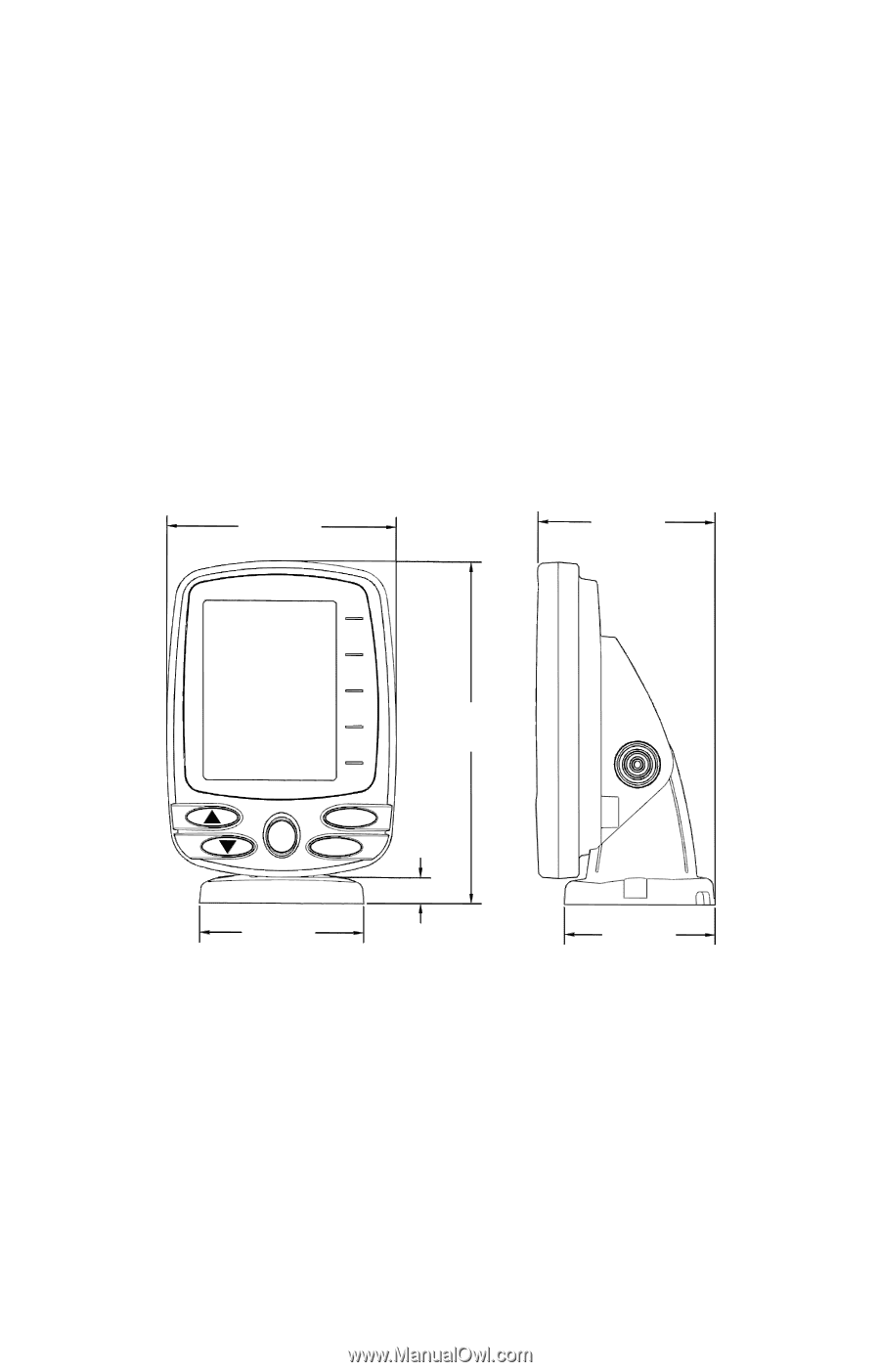

Bracket Installation Recommended tools for this job include: drill, 1" (25.4 mm) drill bit, screwdriver. Required supplies for this job include: high quality, marine grade above- or below-waterline caulking compound, three #10 stainless steel screws. Screw length and type should be suitable for the material on which you intend to mount the bracket. Mount the unit in any convenient location, provided there is clearance when it's tilted for the best viewing angle. You should also make sure there is enough room behind the unit to attach the power/transducer cable. (See the following drawings, which show the dimensions of a gimbal-mounted X-4 Pro sonar unit.) Holes in the bracket's base allow wood screw or through-bolt mounting. You may need to place a piece of plywood on the back side of thin panels to reinforce the panel and secure the mounting hardware. 107.5 [4.23] 82.7 [3.26] 156 [6.26] 76.9 [3.03] 12.09 [0.48] Millimeter [Inch] 70.3 [2.77] Front view (left) and side view (right) showing dimensions of the X-4 Pro when mounted on quick release bracket. Drill a 1" (25.4 mm) hole in the dash for the power/transducer and accessory cables. The best location for this hole is immediately under the gimbal bracket location. This way, the bracket can be installed so that it covers the hole, holds the cables in position and results in a neat installation. Some customers, however, prefer to mount the bracket to the side of the cable hole - it's a matter of personal preference. 17