Maytag MDG17CSAWW Installation Instructions - Page 10

Installation, Instructions, Gasdryer

|

View all Maytag MDG17CSAWW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

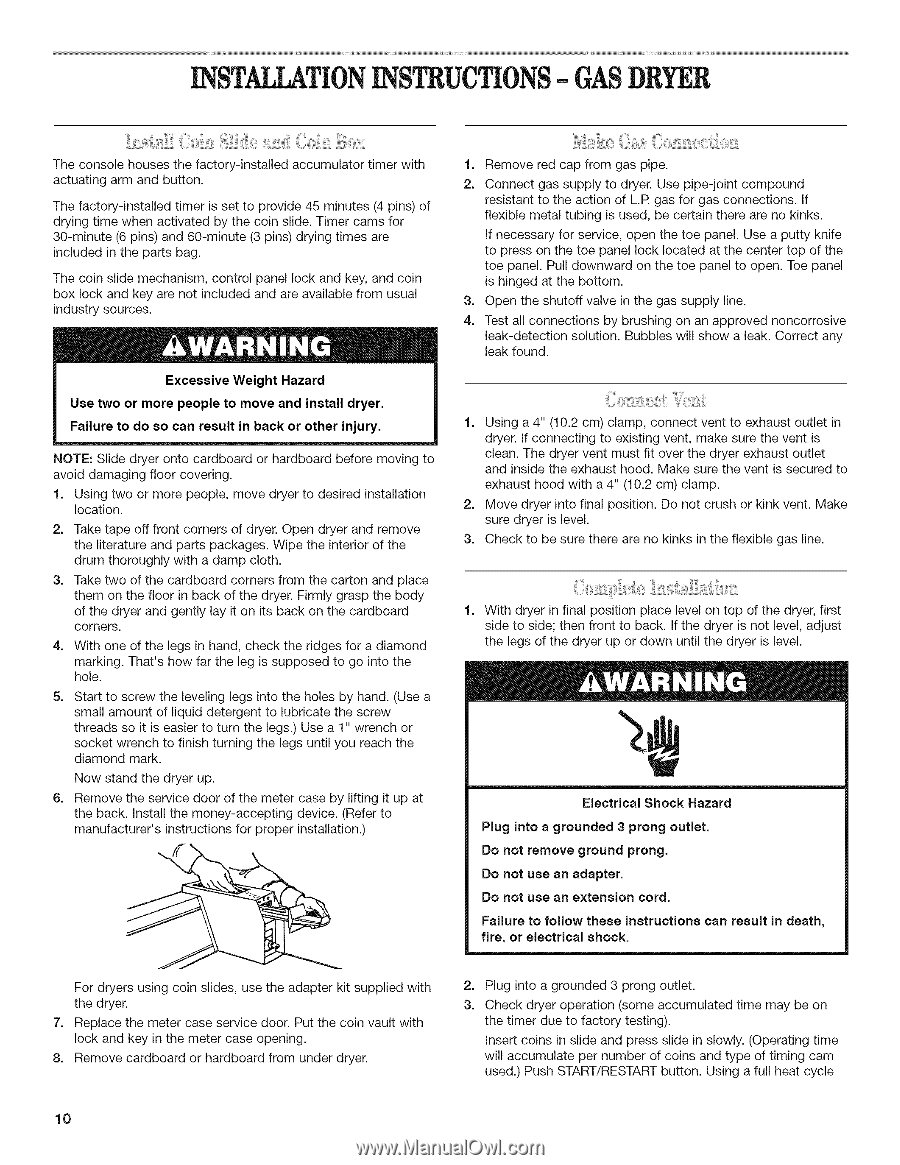

INSTALLATIOINNSTRUCTION-SGASDRYER The console houses the factory-installed accumulator timer with actuating arm and button. The factory-installed timer is set to provide 45 minutes (4 pins) of drying time when activated by the coin slide. Timer cams for 30-minute (6 pins) and 60-minute (3 pins) drying times are included in the parts bag. The coin slide mechanism, control panel lock and key, and coin box lock and key are not included and are available from usual industry sources. Excessive Weight Hazard Use two or more people to move and install dryer. Failure to do so can result in back or other injury. NOTE: Slide dryer onto cardboard or hardboard before moving to avoid damaging floor covering. t. Using two or more people, move dryer to desired installation location. 2. Take tape off front corners of dryer. Open dryer and remove the literature and parts packages. Wipe the interior of the drum thoroughly with a damp cloth. 3. Take two of the cardboard corners from the carton and place them on the floor in back of the dryer. Firmly grasp the body of the dryer and gently lay it on its back on the cardboard corners. 4. With one of the legs in hand, check the ridges for a diamond marking. That's how far the leg is supposed to go into the hole. 5. Start to screw the leveling legs into the holes by hand. (Use a small amount of liquid detergent to lubricate the screw threads so it is easier to turn the legs.) Use a 1" wrench or socket wrench to finish turning the legs until you reach the diamond mark. Now stand the dryer up. 6. Remove the service door of the meter case by lifting it up at the back. Install the money-accepting device. (Refer to manufacturer's instructions for proper installation.) t. Remove red cap from gas pipe. 2. Connect gas supply to dryer. Use pipe-joint compound resistant to the action of L.R gas for gas connections. If flexible metal tubing is used, be certain there are no kinks. If necessary for service, open the toe panel. Use a putty knife to press on the toe panel lock located at the center top of the toe panel. Pull downward on the toe panel to open. Toe panel is hinged at the bottom. 3= Open the shutoff valve in the gas supply line. 4. Test all connections by brushing on an approved noncorrosive leak-detection solution. Bubbles will show a leak. Correct any leak found. t. Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in dryer. If connecting to existing vent, make sure the vent is clean. The dryer vent must fit over the dryer exhaust outlet and inside the exhaust hood. Make sure the vent is secured to exhaust hood with a 4" (10.2 cm) clamp. 2. Move dryer into final position. Do not crush or kink vent. Make sure dryer is level. 3. Check to be sure there are no kinks in the flexible gas line. With dryer in final position place level on top of the dryer, first side to side; then front to back. If the dryer is not level, adjust the legs of the dryer up or down until the dryer is level. Electrical Shock Hazard Plug into a grounded 3 prong outlet. Do not remove ground prong. Do not use an adapter. Do not use an extension cord. Failure to follow these instructions can result in death, fire, or electrical shock. For dryers using coin slides, use the adapter kit supplied with the dryer. 7. Replace the meter case service door. Put the coin vault with lock and key in the meter case opening. 8. Remove cardboard or hardboard from under dryer. 2= Plug into a grounded 3 prong outlet. 3. Check dryer operation (some accumulated time may be on the timer due to factory testing). Insert coins in slide and press slide in slowly. (Operating time will accumulate per number of coins and type of timing cam used.) Push START/RESTART button. Using a full heat cycle 10