Pentair Pentair Flotec FP5242 1.5 HP Cast Iron Sprinkler Pump Flotec FP5200 Se - Page 9

carefully, NOTICE, INSTALLING NEW SEAL, BE SURE, Be sure you do, not touch capacitor terminals

|

View all Pentair Pentair Flotec FP5242 1.5 HP Cast Iron Sprinkler Pump manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

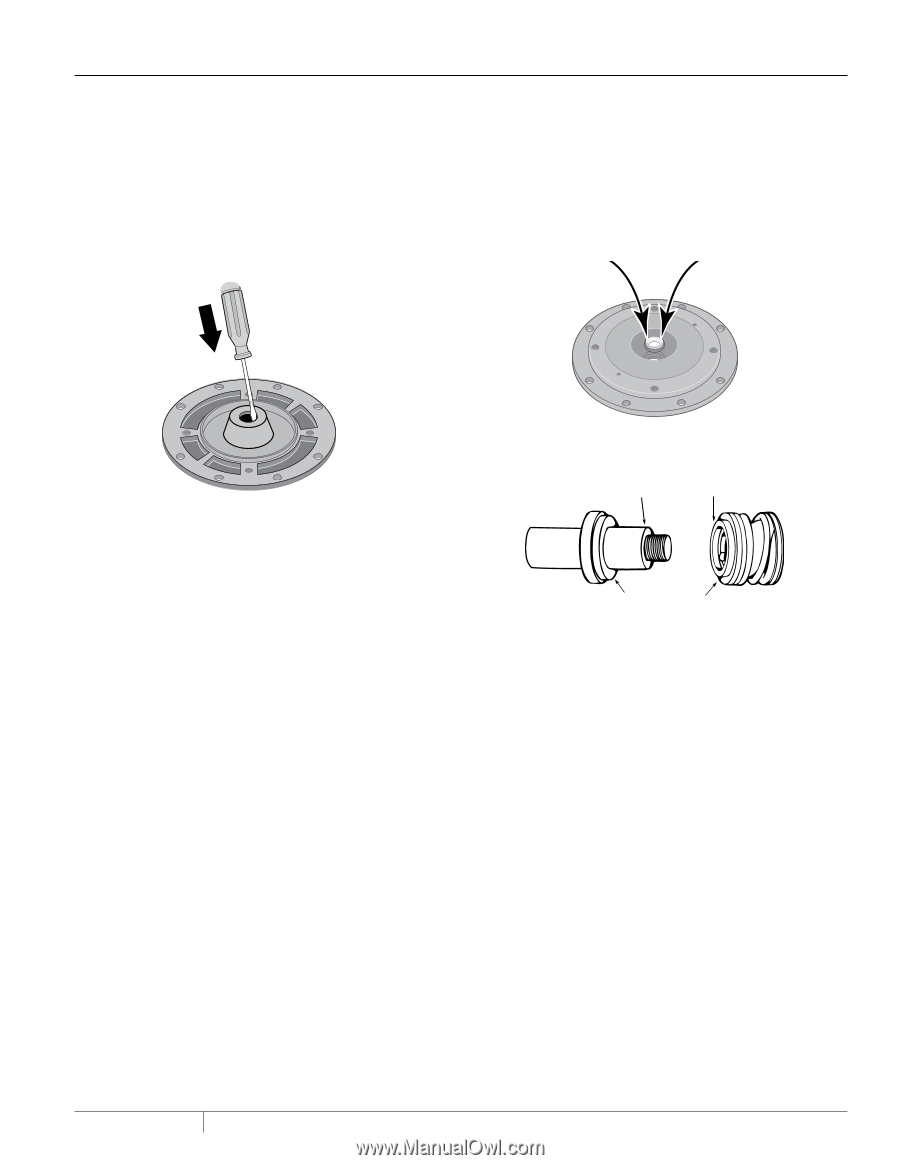

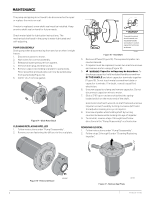

MAINTENANCE 3. Remove rotating half of seal by placing two screwdrivers under seal ring and carefully prying up (Figure 17). 4. Remove nuts from studs holding seal plate to motor. Carefully slide seal plate off of shaft. NOTICE: Be sure you do not scratch or mar shaft. If shaft is marred, it must be dressed smooth with fine emery or crocus cloth before installing new seal. DO NOT reduce shaft diameter! 5. Place seal plate half face down on flat surface and tap out stationary half of seal (Figure 18). NOTICE: Be sure not to nick or scratch carbon face of seal when passing it over threaded shaft end or shaft shoulder. The carbon surface must remain clean or short seal life will result. 10. Hold motor shaft with 7/16" open end wrench on shaft flats and screw impeller onto shaft. Be sure you do not touch capacitor terminals with body or any metal object. Tightening impeller will automatically locate seal in correct position. Figure 18 - Tap Out Se30a30l 0997 INSTALLING NEW SEAL Gaskets and o-rings are not interchangeable per models. Make sure to install the type of gasket or o-ring you removed. 1. Clean seal cavity in seal plate. 2. Sparingly wet outer edge of rubber cup on ceramic seat with liquid soap. 3. Put clean cardboard washer on seal face. The ceramic seal's polished face should be facing up. Firmly and squarely, press ceramic seal into cavity using only hand pressure. 4. If seal will not seat correctly: • Remove seal, placing polished side up on bench. Re- clean cavity and install as outlined in previous step. • If seal still does not seat properly after re-cleaning the cavity, place a cardboard washer over polished seal face and carefully press into place using a piece of standard 3/4 inch pipe as a press being careful not to scratch seal face." 5. Dispose of cardboard washer and recheck seal face to be sure it is free of dirt, foreign particles, scratches and grease. 6. Inspect shaft to be sure it is free of nicks and scratches. 7. Reassemble pump body half to motor flange. BE SURE it is right side up. 8. Apply liquid soap sparingly (one drop is sufficient) to inside diameter of rotating seal member. 9. Slide rotating seal member (carbon face first) onto shaft until rubber drive ring hits shaft shoulder. 3031 0997 Figure 19 - Press in New Seal Be Careful That ...Does Not Damage Motor Shaft Shoulder... Seal Face Ceramic Face Carbon Face Figure 20 - Protect Seal Faces 1072 0697 11. Replace impeller screw (if used) by turning counterclockwise (left-hand thread) into end of shaft. 12. Remount diffuser on seal plate with two screws. 13. Follow instructions under "Pump Reassembly". PUMP REASSEMBLY 1. Install new gasket or O-ring. Note to replace with using the same as the pump was originally manufactured with. 2. Slide motor/seal plate assembly into pump body. Secure with capscrews. 3. Replace base mounting bolts. 4. Replace motor wiring; close draincock. 5. Prime pump according to instructions. See "Operation." 6. Check for leaks. FP30 (11-21-19) 9