Pfaff 131 Owner's Manual - Page 5

regulate, tension, under, thread - 130

|

View all Pfaff 131 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

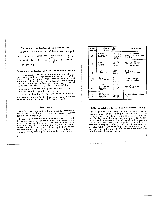

To regulate the tension of the under thread The bobbin case is taken out of the machine then, with the screw-driver, tighten the tension screw Z if the tension is too loose, or , if the tension is too tight (see fig. 3). To regulate the tension of the thread controller spring mtftthhhoeeaurFetnoeatdlrrehdivreaceemlocsarnobdvnoraoeftcrnitoodiitnleghelnthererytrtoetltrelwosenprotserlriionoksnopsngisro.oiernbnnguWwsishshhiosieemnwnnbgeae,dwniwnatthhgroeneadrikta,niddgntBhejguyesitisrttstemeheidmdinacskpyit(loefyinonogsfr.ttioueo4frnnh)n.aitbnhrodgeef a is the position for darning and embroidery work b is the standard position for sewing c is the position for sewing thick or hard materials. The direction for following marks: turning the lever is designated l='loose (light), f=fast (tight). by the The Needle theUstehiPckfanfefssneoefdltehsresaydsteamnd13m0 aintersiiazlesusaepdp,rocpornisauteltintgo table on following page. wiitsutnhhpshseIaneanharltktioosignnrahwdgpngeeiodlsgrlstarstoftiapiobnotkoleveeicienen,hdttoao,tliusnhetlg,etophnetooebhsieettneghitngerincnhoeagtotnerehevednetfeelouedtnlohltweehfet,eeihdttnrhahllaeteeeiefysttdnoe.chlueleePaertmuhdsfcellpehlleaafnttmnsbeechepaseraidreddnlaweleadgen,abodsaiWfanosr.thmhtfhetaaeonert 8 No. of Needles) Sice of Cotton Linen or Silk I Class of Work 70 t7) Cotton Schappe silk Real silk 150-100 150 -1003 150-100/3 (000/001 Very thin fabrics (cambric, tulle, muslin) fine linen Cotton Schappe silk Real silk 100-80 100/3 100'3 (0) Very fine silk goods, fine linen, underwear, fine calicoes etc. Cotton 80-60 )9 Schappe silk Real silk 80/3 80/3 (B) Thick underwear, light knitted goods 100 (10> Cotton Schappe silk Real silk 60-40 70/3 70/3 IC) Ladies' clothings, hems umbrellas Cotton 40-30 110 Schappe silk 60/3 (11) ReaLsilk 60/3. (D) Linen 90-80 Gents' clothings, corsets etc. 120 Cotton Schappe silk 30-24 50/3 I Cloths, winter clothing (121 Real silk 50/3 (E) etc. Linen 80-50 Stitch regulation: Forward and backward sewing The regulation of the length of the stitches is done by means of screw M (fig. 1). M pointing on 0, the feeder does not move at all. Moving screw M upward, the machine is sewing forward, and moving it downward, beyond 0, it is sewing backward. Switching to backward stitches and vice versa, the same length of stitches is retained. Changing the length of the stitches can also be accomplished whilst sewing. When embroidering and darning, choose the 0-position, using the backward stitch only for tying forward seams. 9