Poulan 1981-10 User Manual - Page 14

Sharpening, Chain, Guide, Maintenance

|

View all Poulan 1981-10 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

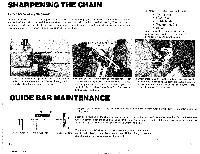

SHARPENING THE CHAIN Remember to wear your gloves! A sharp chain wil l make your cutting chores much easier. The wood chips your saw makes should be about the size of the teeth of the chain. If, instead they are small and powdery, the chain is dull and needs sharpening. When the chain is cutting well, light pressure should be enough. If you have to force the saw through the cut with heavy pressure or if the saw cuts to one side, the chain is dull or the guide bar worn or both. FILE IN ONE DIRECTION ONLY To sharpen your chain you will need: • Your gloves • 5/32" file • 6" file holder • Medium flat file • Gaugit Your Poulan dealer has everything listed. You will also need a vise to hold the guide bar as you sharpen the chain. GAUGIT DEPTH GAUGE 1. Adjust the tension as tightly as you can and still be able to move the chain around the bar. Place guide bar in a vise, clamping the center of the bar. 2. Sharpen all the cutting edges on one side first. Then sharpen the cutting edges on the other side. Mark your starting point so you will know when you have finished. File in 1 direction only - 2 or 3 strokes per cutting edge is sufficient. 3. After sharpening the cutting edges, place the gaugit over the depth gauge. If the depth gauge sticks out, file it off with the flat file. Do this for each depth gauge. Your chain should now be sharp. GUIDE BAR MAINTENANCE VEMENtai itr ^7 Wear your gloves. Work in a lighted area with chain cooled off. A worn guide bar will damage the chain and make cutting harder. Check the underside of the chain for wear which could be causing wear to the guide bar. A lack of OIL in the chain oil tank can damage both the chain and the bar. Make sure there is oil in the tank and that you have proper tension on the chain. Improper tension will also cause excessive wear to guide bar. Correct Groove Worn Grooves File Edges Square The figure on the left shows a cross-section of the guide bar groove. Check the tip and rails of the guide bar often for wear. If the inside groove of the guide bar rail or nose is worn replace the guide bar. 14 - 04007 wren