Poulan 4400-4900-5400 User Manual - Page 13

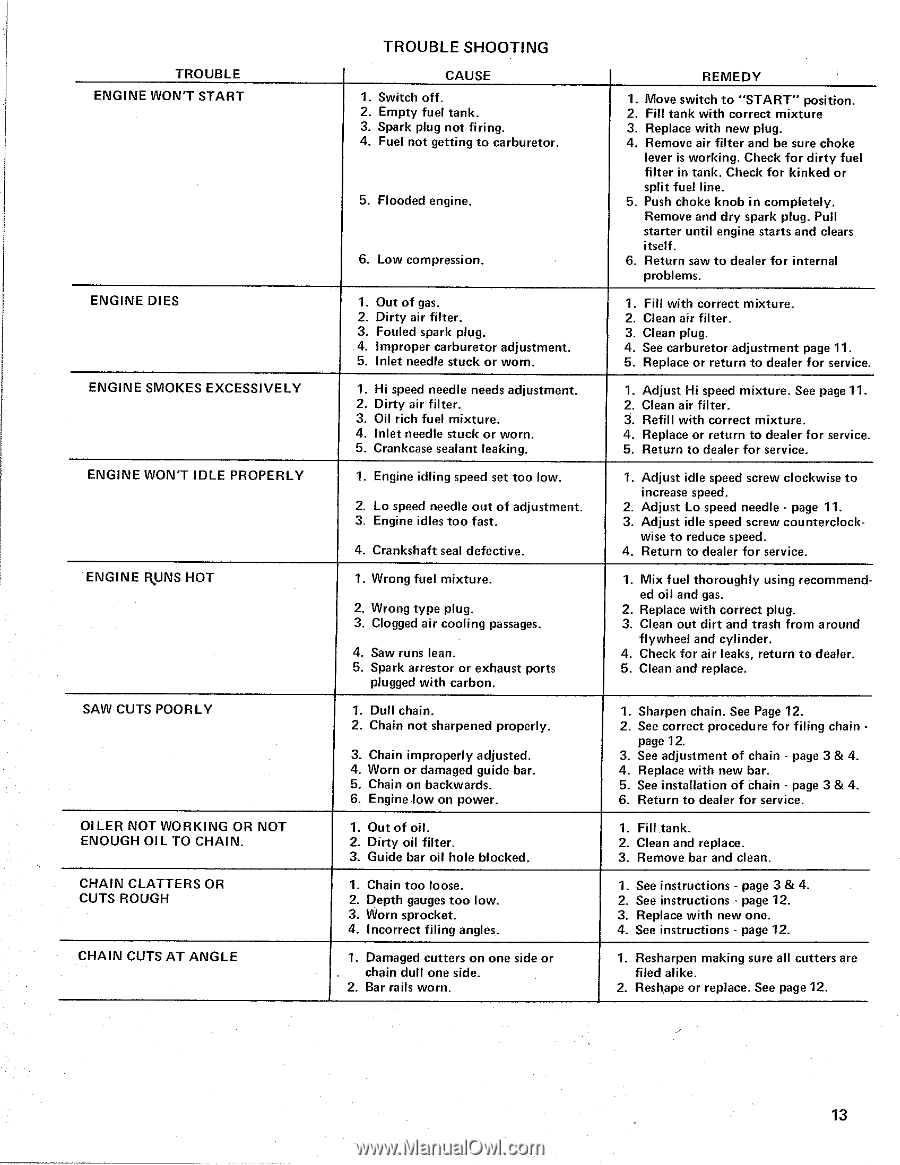

Trouble, Shooting

|

View all Poulan 4400-4900-5400 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

TROUBLE ENGINE WON'T START ENGINE DIES ENGINE SMOKES EXCESSIVELY ENGINE WON'T IDLE PROPERLY ENGINE RUNS HOT SAW CUTS POORLY OILER NOT WORKING OR NOT ENOUGH OIL TO CHAIN. CHAIN CLATTERS OR CUTS ROUGH CHAIN CUTS AT ANGLE TROUBLE SHOOTING CAUSE 1. Switch off. 2. Empty fuel tank. 3. Spark plug not firing. 4. Fuel not getting to carburetor. 5. Flooded engine. 6. Low compression. 1. Out of gas. 2. Dirty air filter. 3. Fouled spark plug. 4. Improper carburetor adjustment. 5. Inlet needle stuck or worn. 1. Hi speed needle needs adjustment. 2. Dirty air filter. 3. Oil rich fuel mixture. 4. Inlet needle stuck or worn. 5. Crankcase sealant leaking. 1. Engine idling speed set too low. 2. Lo speed needle out of adjustment. 3. Engine idles too fast. 4. Crankshaft seal defective. 1. Wrong fuel mixture. 2. Wrong type plug. 3. Clogged air cooling passages. 4. Saw runs lean. 5. Spark arrestor or exhaust ports plugged with carbon. 1. Dull chain. 2. Chain not sharpened properly. 3. Chain improperly adjusted. 4. Worn or damaged guide bar. 5. Chain on backwards. 6. Engine low on power. 1. Out of oil. 2. Dirty oil filter. 3. Guide bar oil hole blocked. 1. Chain too loose. 2. Depth gauges too low. 3. Worn sprocket. 4. Incorrect filing angles. 1. Damaged cutters on one side or . chain dull one side. 2. Bar rails worn. REMEDY 1. Move switch to "START" position. 2. Fill tank with correct mixture 3. Replace with new plug. 4. Remove air filter and be sure choke lever is working. Check for dirty fuel filter in tank. Check for kinked or split fuel line. 5. Push choke knob in completely. Remove and dry spark plug. Pull starter until engine starts and clears itself. 6. Return saw to dealer for internal problems. 1. Fill with correct mixture. 2. Clean air filter. 3. Clean plug. 4. See carburetor adjustment page 11. 5. Replace or return to dealer for service. 1. Adjust Hi speed mixture. See page 11. 2. Clean air filter. 3. Refill with correct mixture. 4. Replace or return to dealer for service. 5. Return to dealer for service. 1. Adjust idle speed screw clockwise to increase speed. 2. Adjust Lo speed needle - page 11. 3. Adjust idle speed screw counterclock- wise to reduce speed. 4. Return to dealer for service. 1. Mix fuel thoroughly using recommended oil and gas. 2. Replace with correct plug. 3. Clean out dirt and trash from around flywheel and cylinder. 4. Check for air leaks, return to dealer. 5. Clean and replace. 1. Sharpen chain. See Page 12. 2. See correct procedure for filing chain - page 12. 3. See adjustment of chain - page 3 & 4. 4. Replace with new bar. 5. See installation of chain - page 3 & 4. 6. Return to dealer for service. 1. Fill tank. 2. Clean and replace. 3. Remove bar and clean. 1. See instructions - page 3 & 4. 2. See instructions - page 12. 3. Replace with new one. 4. See instructions - page 12. 1. Resharpen making sure all cutters are filed alike. 2. Reshape or replace. See page 12. 13