Poulan PR25PH48STC User Manual - Page 23

To Adjust Steering Wheel Alignment

|

View all Poulan PR25PH48STC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

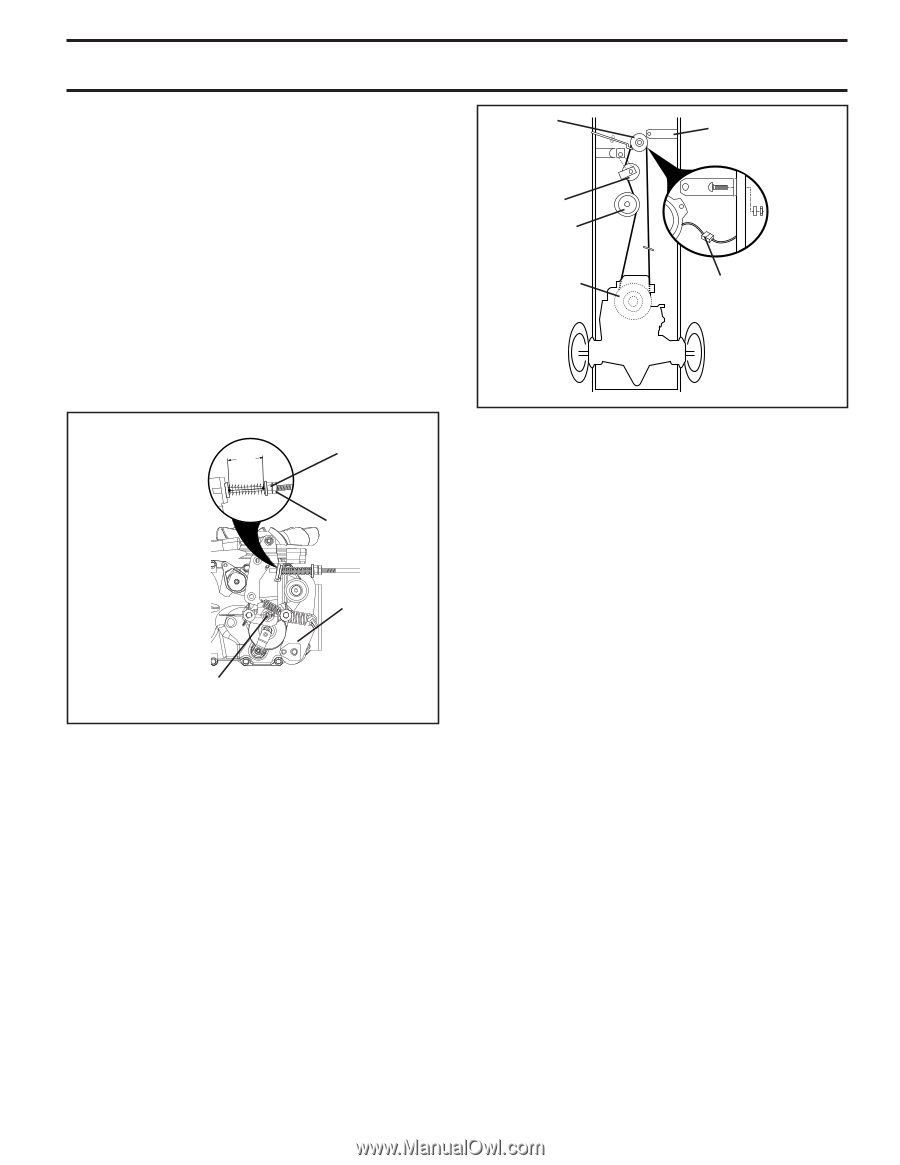

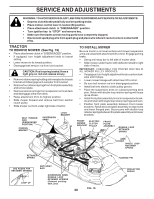

SERVICE AND ADJUSTMENTS The rear wheels must lock and skid when you try to manually push the tractor forward. If the rear wheels rotate, the brake needs to be adjusted or the pads need to be replaced. TO ADJUST BRAKE • Depress clutch/brake pedal all the way down and en- gage parking brake. • Measure distance between brake operating arm and nut "A" on brake rod. • If distance is other than 1-3/4", loosen jam nut and turn nut "A" until distance becomes 1-3/4". Retighten jam nut against nut "A". • Engage transmission by placing freewheel control in "transmission engaged" position. • Road test tractor for proper stopping distance as stated above. Readjust if necessary. If stopping distance is still greater than five (5) feet in highest gear, further maintenance is necessary. Replace brake pads or contact a qualified service center. WITH PARKING BRAKE "ENGAGED" 1-3/4" NUT "A" JAM NUT OPERATING ARM DO NOT TOUCH THIS NUT. IF FURTHER BRAKE ADJUSTMENT IS NECESSARY CONTACT YOUR NEAREST AUTHORIZED SERVICE CENTER/DEPARTMENT FIG. 26 TO REPLACE MOTION DRIVE BELT (See Fig. 27) Park the tractor on level surface. Engage parking brake. For assistance, there is a belt installation guide decal on bottom side of left footrest. • Remove mower (See "TO REMOVE MOWER" in this section of this manual.) • Disconnect clutch wire harness. • Remove clutch locator. • Remove belt from stationary idler and clutching idler. • Pull belt slack toward rear of tractor. Carefully remove belt upwards from transmission input pulley and over cooling fan blades. • Pull belt toward front of tractor and remove downwards from around electric clutch. • Install new belt by reversing above procedure. ELECTRIC CLUTCH CLUTCHING IDLER STATIONARY IDLER TRANSMISSION INPUT PULLEY CLUTCH LOCATOR CLUTCH WIRE HARNESS FIG. 27 TRANSMISSION REMOVAL/REPLACEMENT Should your transmission require removal for service or replacement, it should be purged after reinstallation and before operating the tractor. See "PURGE TRANSMISSION" in the Operation section of this manual. TO ADJUST STEERING WHEEL ALIGNMENT If steering wheel crossbars are not horizontal (left to right) when wheels are positioned straight forward, remove steering wheel and reassemble per instructions in the Assembly section of this manual. FRONT WHEEL TOE-IN/CAMBER The front wheel toe-in and camber are not adjustable on your tractor. If damage has occurred to affect the front wheel toein or camber, contact your nearest authorized service center/department. TO REMOVE WHEEL FOR REPAIRS (See Fig. 28) • Block up axle securely. • Remove axle cover, retaining ring and washers to allow wheel removal (rear wheel contains a square key - Do not lose). • Repair tire and reassemble. • On rear wheels only: align grooves in rear wheel hub and axle. Insert square key. • Replace washers and snap retaining ring securely in axle groove. • Replace axle cover. NOTE: To seal tire punctures and prevent flat tires due to slow leaks, tire sealant may be purchased from your local parts dealer. Tire sealant also prevents tire dry rot and corrosion. 23