Ricoh Pro 8120s Manuals - Page 8

Resistance to Heat, Moisture Content, If the humidity is high in the place where the paper is stored - toner

|

View all Ricoh Pro 8120s manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

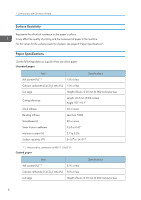

1. Characteristics and Conditions of Paper If an area has solid printing, it may not be uniform when using paper with a rough surface. On the other hand, the toner may not fuse to the paper properly if the surface of the paper is too smooth. In addition, if paper has a smooth surface, each of the sheets is likely to stick together, and therefore the paper may not feed correctly inside the machine. Printing on embossed paper may produce irregularities in print quality or deterioration in the ability to fuse toner. Moreover, the paper may not feed correctly in the machine. For the values for the surface smoothness of paper, see page 8 "Paper Specifications". Resistance to Heat Paper is exposed to high temperatures inside the machine when toner is fused to the paper. Because of this, it is necessary for the paper to maintain the same qualities even when exposed to high temperatures. Use a paper that does not dissolve, vaporize, change color, or cause set-off printing when exposed to high temperatures during the fusing process. Also, do not use paper that peels off in layers. Moisture Content The moisture content of paper affects the condition of the paper and print quality. If the moisture content ratio is too high, the edge of the paper may warp and become wavy. In addition, the paper may wrinkle during printing and reduce print quality, such as decreasing print density. Wavy paper If the humidity is high in the place where the paper is stored, paper that is exposed to air may absorb moisture and the edges may become wavy. The paper may not feed through the machine, or feed at an angle because the heights of the edge and the center part of wavy paper are different. Also, wrinkling, and curling may occur during printing. Use paper that has a difference of 2 mm (0.08 inches) or less between the top sheet's highest and lowest point when the maximum number of sheets of paper is loaded in the paper. 1 CEL001 6