Ryobi D47CK English Manual - Page 12

Adjustable Torque Clutch

|

View all Ryobi D47CK manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

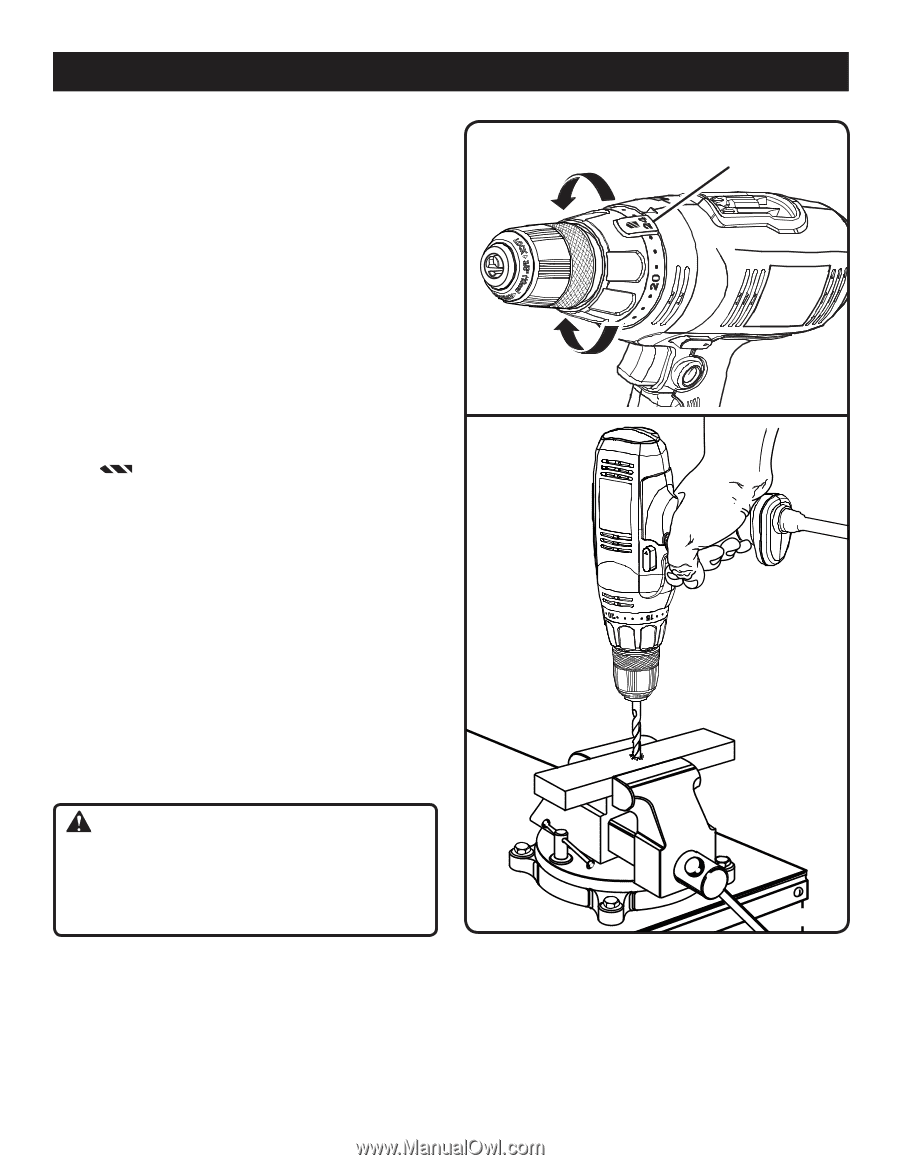

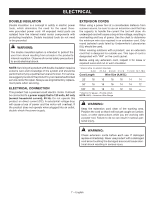

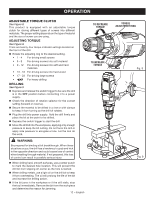

OPERATION adjustable torque clutch See Figure 8. This product is equipped with an adjustable torque clutch for driving different types of screws into different materials. The proper setting depends on the type of material and the size of screw you are using. ADJUSTing TORQUE See Figure 8. There are twenty-four torque indicator settings located on the front of the drill. Rotate the adjusting ring to the desired setting. • 1 - 4 For driving small screws • 5 - 8 For driving screws into soft material • 9 - 12 For driving screws into soft and hard materials • 13 - 16 For driving screws into hard wood • 17 - 23 For driving large screws • For heavy drilling DRILLING See Figure 9. Depress and release the switch trigger to be sure the drill is in the OFF position before connecting it to a power supply. Check the direction of rotation selector for the correct setting (forward or reverse). Secure the material to be drilled in a vise or with clamps to keep it from turning as the drill bit rotates. Plug the drill into power supply. Hold the drill firmly and place the bit at the point to be drilled. Depress the switch trigger to start the drill. Move the drill bit into the workpiece, applying only enough pressure to keep the bit cutting. Do not force the drill or apply side pressure to elongate a hole. Let the tool do the work. WARNING: Be prepared for binding at bit breakthrough. When these situations occur, the drill has a tendency to grab and kick in the opposite direction and could cause loss of control when breaking through material. If not prepared, this loss of control can result in possible serious injury. When drilling hard, smooth surfaces, use a center punch to mark the desired hole location. This will prevent the drill bit from slipping off-center as the hole is started. When drilling metals, use a light oil on the drill bit to keep it from overheating. The oil will prolong the life of the bit and increase the drilling action. If the bit jams in the workpiece or if the drill stalls, stop the tool immediately. Remove the bit from the workpiece and determine the reason for jamming. 12 − English TO DECREASE TORQUE TO INCREASE TORQUE TORQUE ADJUSTMENT RING Fig. 8 Fig. 9