Ryobi HP612K English Manual - Page 16

Adjustable Torque Clutch, Adjusting Torque

|

View all Ryobi HP612K manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

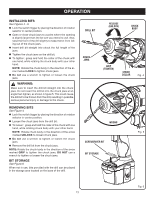

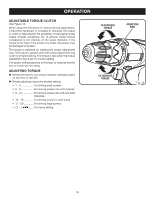

operation ADJUSTABLE TORQUE CLUTCH See Figure 12. When using the drill-driver for various driving applications, it becomes necessary to increase or decrease the torque in order to help prevent the possibility of damaging screw heads, threads, workpiece, etc. In general, torque should correspond to the intensity of the screw diameter. If the torque is too high or the screws too small, the screws may be damaged or broken. The torque is adjusted by rotating the torque adjustment ring. The torque is greater when the torque adjustment ring is set on a higher setting. The torque is less when the torque adjustment ring is set on a lower setting. The proper setting depends on the type of material and the size of screw you are using. ADJUSTing torque Identify the twenty four torque indicator settings located on the front of the drill. Rotate adjusting ring to the desired setting. • 1 - 4 For driving small screws • 5 - 8 For driving screws into soft material • 9 - 12 For driving screws into soft and hard materials • 13 - 16 For driving screws in hard wood • 17 - 20 For driving large screws • 21 - ( )...... For heavy drilling to decrease torque to increase torque adjusting ring Fig. 12 16