Seiko 9R65 Manual - Page 5

Spring Drive Mechanism ③, Differences between the Spring, Drive and mechanical watch

|

View all Seiko 9R65 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

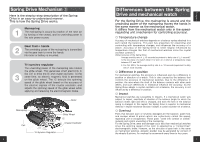

Spring Drive Mechanism ③ Here is the step-by-step description of the Spring Drive in an easy-to-understand manner. This is how the Spring Drive works. Mainspring 1 The mainspring is wound by rotation of the rotor (or by turning of the crown), and its unwinding power is the sole power source. Gear train • hands 2 The unwinding power of the mainspring is transmitted via the gear train to move the hands. No motor or battery is mounted. Tri-synchro regulator The unwinding power of the mainspring also rotates the glide wheel. This generates small electricity in the coil to drive the IC and crystal oscillator. At the 3 same time, an electric magnetic field is generated on the glide wheel. The IC detects the spinning speed of the glide wheel based on the accuracy of the electric signals of the crystal oscillator, and adjusts the spinning speed of the glide wheel while applying and releasing the electromagnetic brake. Rotor Mainspring Coil Glide Wheel IC Crystal Oscillator Tri-Synchro Regulator 6 Differences between the Spring Drive and mechanical watch For the Spring Drive, the mainspring is wound and the unwinding power of the mainspring moves the hands in the same manner as the mechanical watch. It differs from the mechanical watch only in the speedregulating unit (mechanism for controlling accuracy). ◎ Temperature change Accuracy of mechanical watches depends on a balance spring attached to a part called the balance. This part has properties for expanding and contracting with temperature changes, and influences the accuracy of a watch. Accuracy of the Spring Drive is never largely influenced by temperature changes like that of mechanical watches since the crystal oscillator controls it. (Note) Accuracy of the Spring Drive Average monthly rate of ±15 seconds (equivalent to daily rate of ±1 second)※ is the accuracy of a watch when it is worn on a wrist at a temperature range between 5℃ and 35℃. ※ For Cal. 9R15, the average monthly rate is ± 10 seconds (equivalent to daily rate of ±0.5 second). ◎ Difference in position For mechanical watches, the accuracy is influenced even by a difference in position or direction of a watch. This is also caused by the balance that controls the accuracy of mechanical watches. Due to the difference in position, the area where the shaft of the balance contacts with other parts differs, and such differences in resistance influence the accuracy. As the Spring Drive adopts a crystal oscillator not a balance, the accuracy is not influenced by a difference in position. ◎ Impact Mechanical watches are susceptible to impacts. If a mechanical watch was subject to impact, amplitude of vibration of the balance (angle for which the balance rotates right and left) is changed, and even the form of the balance spring is changed. In this regard, the Spring Drive is superior to mechanical watches in impact resistance because it adopts a crystal oscillator not a balance. ◎ Overhaul Parts that become worn or severely damaged are the balance, pallet fork, and escape wheel & pinion which are collectively called the speedregulating unit or escapement. These parts"come into contact or collide" mutually and control unwinding of the mainspring. For the Spring Drive, wear and damage occur less than mechanical watches since the spinning speed of the rotor is adjusted by a"contact-free" electromagnetic brake. However, as the structure of gear train is the same as mechanical watches, abrasion powder may be generated by contact of the wheels & pinions. An overhaul is recommend every three to four years. 7 English