Singer 1409 Promise Instruction Manual - Page 29

Checking, Performance, Problems - how to thread a sewing machine

|

View all Singer 1409 Promise manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

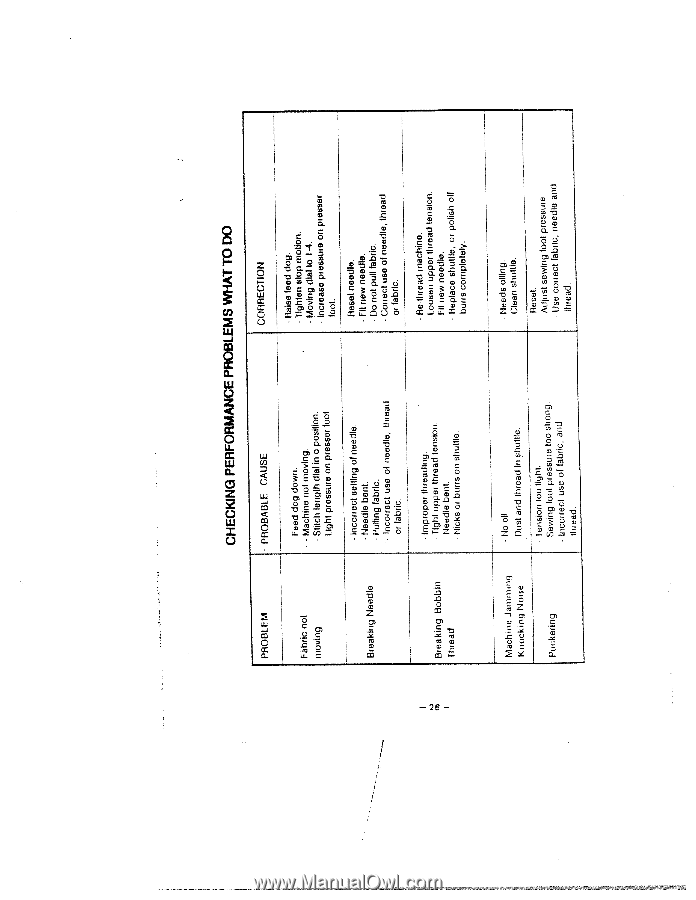

PROBLEM Fabric not moving Breaking Needle Breaking Bobbin Thread CHECKING PERFORMANCE PROBLEMS WHAT TO DO PROBABLE CAUSE Feed dog down. - Machine not moving. - Stitch length dial no positicn. - Light pressure on presser loot. - Incorrect setting of needle. - Needle bent. Pulling fabric. Incorrect use of needle, thread or fabric. - Improper threading. - Tight upper thread tension. . Needle bent. . Nicks or burrs on shuttle. CORRECTION - Raise feed dog. - ghbei etop mollon. * oving dial to 1-4. Increase pressure on presser toot. Reset needle. . Fit new needle. - Do not pull fabric. - Correct use of needle, thread or fabric. - Re-thread machine. . Ioosen upper thread tension. . Fit new needle. - Replace shuttle, or polish oil burrs completely. Machine Jamming Knocking Noise Puckering - No oil. Dust and thread in shuttle. Tension too tight. Sewing toot pressure too strong - Incorrect use of fabric, and thread, - [leeds oiling Glean stmutlle. - -Reset. - Adlust sewing loot pmessure - Use correct fabric, needle and thread.