Tecumseh Products HSK600 Operator Manual - Page 14

Adjustments, Muffler and Cylinder Exhaust Ports, Spark Plug, Removing Snow from Engine - recoil starter

|

View all Tecumseh Products HSK600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

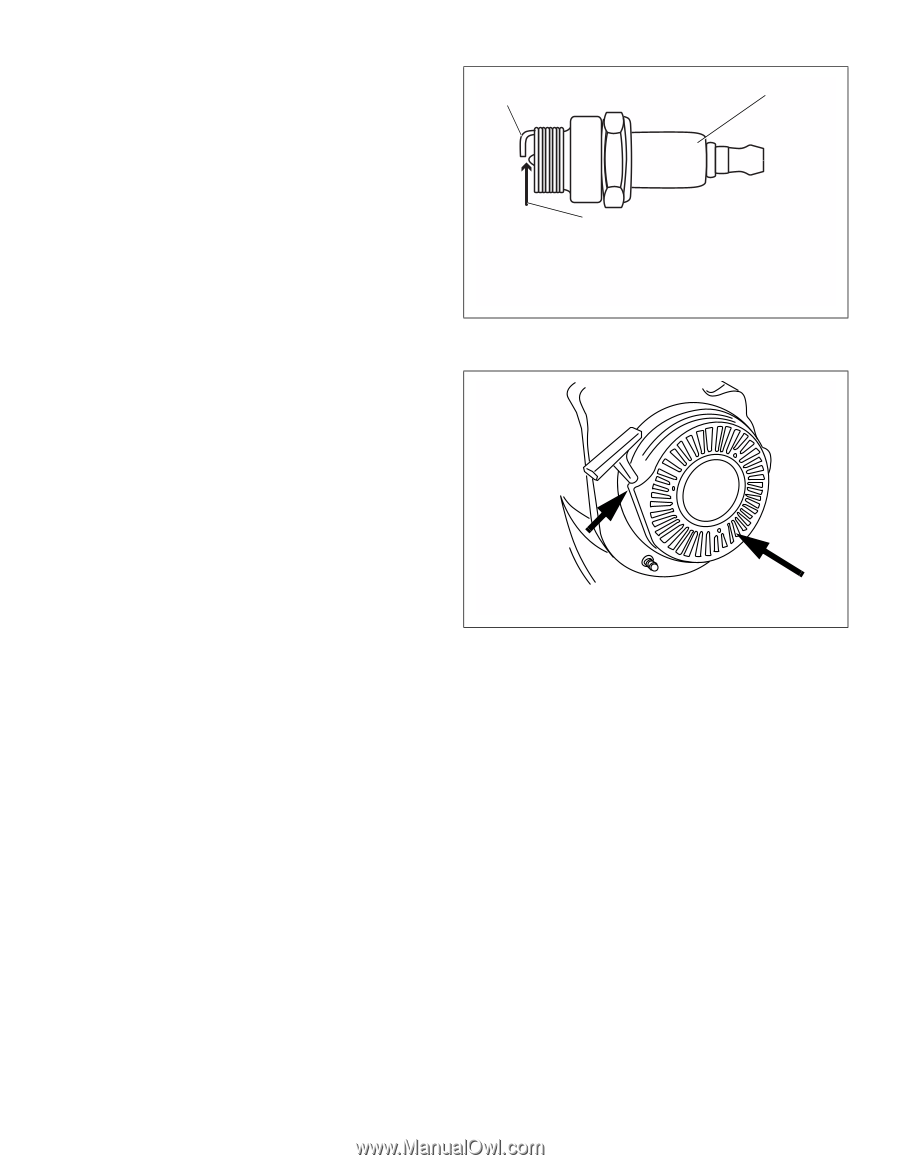

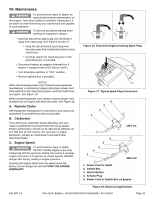

D. Adjustments DO NOT make any engine adjustments. Factory settings are satisfactory for most conditions. If adjustments are needed, contact your Authorized TecumsehPower Servicing Dealer. E. Muffler and Cylinder Exhaust Ports The muffler and cylinder exhaust ports require cleaning after every 75 to 100 hours of operation. NOTE For this maintenance procedure it is recommended that the engine be taken to an Authorized TecumsehPower Servicing Dealer. F. Spark Plug Check spark plug yearly or every 100 operating hours. 1. Clean area around spark plug. 2. Remove and inspect spark plug. 3. Replace spark plug if porcelain is cracked or if electrodes are: • Pitted • Burned • Fouled with Deposits 4. Check electrode gap with wire feeler gauge and set gap to-.030 in. (0.76 mm) if necessary. See Figure 19. 5. Install spark plug and tighten securely. NOTE A resistor spark plug must be used for replacement. Contact your Authorized TecumsehPower Servicing Dealer for a genuine replacement Resistor Spark Plug. G. Removing Snow from Engine After each use remove snow from the following areas: • Fuel Fill Cap • Recoil Starter Screen • Control Lever NOTES See equipment manufacturer's instructions for proper location of fuel fill cap and control lever. Removing snow will ease operation of the recoil starter rope and reduce the risk of water contamination when opening fuel fill cap. See Figure 20. For more information about recoil starters, see "B. Engines with Recoil Starters" instructions on page 8. 2 3 1 1. .030 in. (0.76 mm) Gap 2. Electrodes 3. Porcelain Figure 19. Resistor Spark Plug Figure 20. Recoil Starter Debris Areas Page 12 Two-Cycle Engine • Horizontal/Vertical Crankshaft • Air-Cooled 181-807-14