Troy-Bilt CSV 206 Operation Manual - Page 15

Troubleshooting - lowe s

|

View all Troy-Bilt CSV 206 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

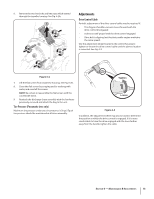

Troubleshooting 8 Problem Cause Remedy Engine Fails to start Engine runs erratic Engine overheats Occasional skips (hesitates) at high speed Excessive Vibration Unit does not discharge Rate of discharge slows considerably or composition of discharged material changes Unit fails to propel itself or slips when drive control is engaged 1. Throttle lever not in correct starting position. 2. Spark plug wire disconnected. 3. Choke not in CHOKE position (if equipped). 4. Fuel tank empty or stale fuel. 5. Engine not primed (if equipped). 6. Faulty spark plug. 7. Engine flooded. 1. Spark plug boot loose. 2. Unit running on CHOKE (if equipped). 3. Blocked fuel line or stale fuel. 4. Low engine RPM. 5. Water or dirt in fuel system. 6. Dirty air cleaner. 7. Carburetor out of adjustment. 1. Engine oil level low. 2. Dirty air cleaner. 1. Spark plug gap too close. 2. Carburetor idle mixture adjustment improperly set. 1. Loose parts or damaged impeller. 1. Discharge area clogged. 2. Foreign object lodged in impeller. 3. Low engine RPM. 4. Vacuum bag is full. 1. Low engine RPM. 2. Chipper blade dull. 1. Drive control cable out of adjustment. 2. Drive belt worn or damaged. 1. Move throttle lever to FAST or START position. 2. Connect wire to spark plug. 3. Move choke lever to CHOKE position. 4. Fill tank with clean, fresh gasoline. 5. Prime engine as instructed in Engine Manual. 6. Clean, adjust gap, or replace. 7. Wait a few minutes to restart, but do not prime. 1. Connect and tighten spark plug boot. 2. Move choke lever to OFF position. 3. Clean fuel line; fill tank with clean, fresh gasoline. 4. Always run engine at full throttle. 5. Drain fuel tank. Refill with fresh fuel. 6. Refer to engine manual. 7. See authorized service dealer. 1. Fill crankcase with proper oil. 2. Refer to engine manual. 1. Remove spark plug and adjust gap to .030". 2. See authorized service dealer. 2. See authorized service dealer. 1. Stop engine immediately and disconnect spark plug wire. Clean flail screen and inside of discharge opening. 2. Stop engine and disconnect spark plug wire. Remove lodged object. 3. Always run engine at full throttle. 4. Empty bag. 1. Always run engine at full throttle. 2. Replace chipper blade or see your authorized service dealer. 1. Follow adjustment procedure in Maintenance & Adjustments section of manual. 2. See authorized service dealer. 15