Whirlpool WGD5300VW Dimension Guide - Page 1

Whirlpool WGD5300VW - 7.0 Cu Ft Manual

|

UPC - 883049147673

View all Whirlpool WGD5300VW manuals

Add to My Manuals

Save this manual to your list of manuals |

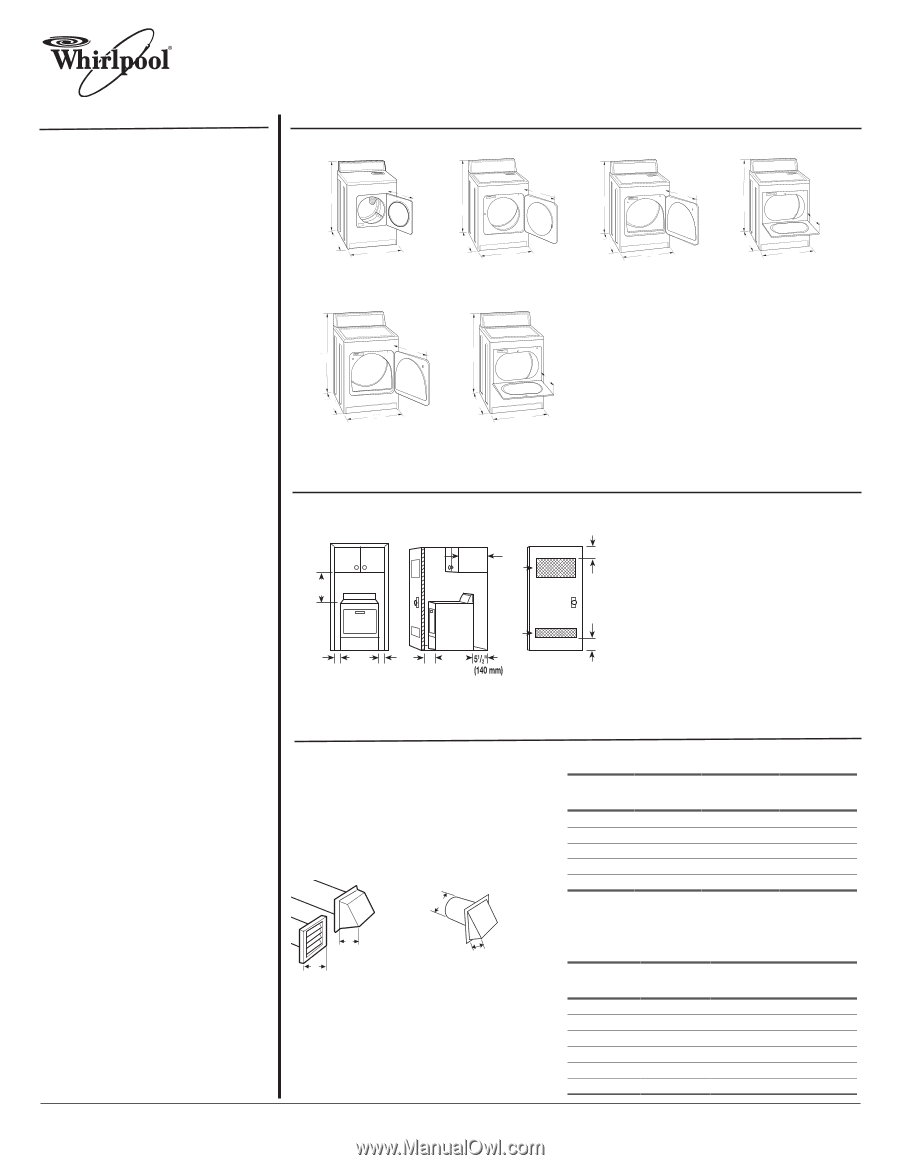

Page 1 highlights

29" and 27" Gas Dryer PRODUCT MODEL NUMBERS WGD5000V WGD5100V WGD5200V WGD5300V WGD5510V WGD5590V WGD5600V WGD5700V Gas supply: This dryer is equipped for use with Natural gas. It is design-certified by CSA International for LP (propane or butane) gases with appropriate conversion. The gas line must include 1/8" NPT minimum plugged tapping accessible for test gauge connection, immediately upstream of the gas connection to the dryer. 1/2" IPS pipe is recommended. 3/8" approved aluminum or copper tubing is acceptable for lengths under 20 ft (6.1 m) if local codes and gas supplier permit. If you are using Natural gas, do not use copper tubing. 3/8" flare x 3/8" NPT adapter fitting between dryer pipe and 3/8" approved tubing. Lengths over 20 ft (6.1 m) should use larger tubing and a different size adapter fitting. If your dryer has been converted to use LP gas, 3/8" LP compatible copper tubing can be used. If the total length of the supply line is more than 20 ft (6.1 m), use larger pipe. NOTE: Pipe-joint compounds that resist the action of LP gas must be used. Do not use TEFLON®† tape. Must include a shutoff valve. In the U.S.A.: An individual manual shutoff valve must be installed within six (6) feet (1.8 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1. In Canada: An individual manual shutoff valve must be installed in accordance with the B149.1, Natural Gas and Propane Installation Code. It is recommended that an individual manual shutoff valve be installed within six (6) feet (1.8 m) of the dryer. The location should be easy to reach for opening and closing. Electrical: 120-volt, 60-Hz, AC-only, 15- or 20-amp fused electrical supply is required. A time-delay fuse or circuit breaker is recommended. It is also recommended that a separate circuit serving only this dryer be provided. Exhaust venting: Exhaust your dryer to the outside. 4" (102 mm) diameter vent is required. Rigid or flexible metal exhaust vent must be used. Do Not use plastic or metal foil vent. Exhaust outlet hood must be at least 12" (305 mm) from the ground or any object that may be in the path of the exhaust. †®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company. PRODUCT DIMENSIONS 29" Model 433/8" (1102 mm) *26" (660 mm) 151/4" (387 mm) 433/8" (1102 mm) 29" (737 mm) A. *273/4" (705 mm) 223/4" (578 mm) 433/8" (1102 mm) 29" (737 mm) B. *273/4" (705 mm) 223/4" (578 mm) 433/8" (1102 mm) 29" (737 mm) C. *273/4" (705 mm) 133/4" (349 mm) 29" (737 mm) D. 27" Model 43 " (1092 mm) 23 3/4" (603 mm) 43" (1092 mm) 13 3/4" (349 mm) A. Small Opening Side-Swing Door B. Large Opening Side-Swing Door C. Wide Opening Side-Swing Door D. Wide Opening Hamper Door *29 1/2" (749 mm) 27 " (687 mm) B. *29 1/2" (749 mm) 27 " (687 mm) D. Most installations require a minimum 5 1/2" (140 mm) clearance behind the dryer for the exhaust vent with elbow. RECESSED AREA AND CLOSET INSTALLATION For closet installation with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable. 18"* (457 mm) 14" max.* (356 mm) 48 in.2* (310 cm )2 3"* (76 mm) 1" (25 mm) 29" (737 mm) 27" (686 mm) A. 1" 1"* 27¾" (25 mm) (25 mm) (705 mm) 29¾1/4" (705 mm) B. EXHAUST VENTING 24 in.2* (155 cm )2 3"* (76 mm) C. A. Recessed area B. Side view - closet or confined area C. Closet door with vents *Required spacing Exhaust your dryer to the outside. 4" (102 mm) diameter vent is required. Rigid or flexible metal exhaust vent must be used. Do not use plastic or metal foil vet. Exhaust hood must be at least 12" (305 mm) from the ground or any object that may be in the path of the exhaust. Hood styles: Box and Louvered hoods styles are recommended. (1024m" m) Box hood style 4" (102 mm) 4" Louvered style (102 mm) 2.5" (64 mm) Acceptable hood style The vent system chart provides venting requirments that will help to achieve the best drying performance. Vent system chart: NOTE: Side and bottom exhaust installations have a 90° turn inside the dryer. To determine maximum exhaust length, add one 90° turn to the chart. Vent System Chart Number Type of vent Box/louvered Angled hoods 90° turns or hoods elbows 0 Rigid metal 64 ft. (20 m) 58 ft. (17.7 m) 1 Rigid metal 54 ft. (16.5 m) 48 ft. (14.6 m) 2 Rigid metal 44 ft. (13.4 m) 38 ft. (11.6 m) 3 Rigid metal 35 ft. (10.7 m) 29 ft. (8.8 m) 4 Rigid metal 27 ft. (8.2 m) 21 ft. (6.4 m) NOTE: Side and bottom exhaust installations for 27" wide models have a 90º turn inside the dryer. To determine maximum exhaust length, add one 90º turn to the chart. Vent System Chart (29" Wide Long Vent Models Only) Number 90° turns or elbows 0 1 2 3 4 5 Type of vent Rigid metal Rigid metal Rigid metal Rigid metal Rigid metal Rigid metal Box, louvered, or angled hoods 120 ft. (36.6 m) 110 ft. (33.5 m) 100 ft. (30.5 m) 90 ft. (27.4 m) 80 ft. (24.4 m) 70 ft. (21.3 m) Because Whirlpool Corporation policy includes a continuous commitment to improve Dimensions are for planning purposes only. For complete details, see Installation our products, we reserve the right to change materials and specifications without notice. Instructions packed with product. Specifications subject to change without notice. Ref. W10296135 12/2009