Whirlpool WGD6400SW Use and Care Guide - Page 10

Install Vent System, Install Leveling Legs, Make Gas Connection - parts

|

UPC - 883049025117

View all Whirlpool WGD6400SW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

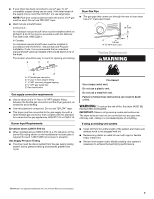

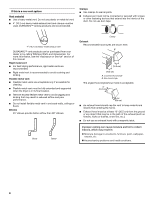

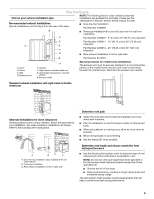

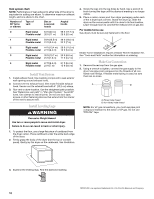

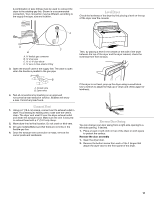

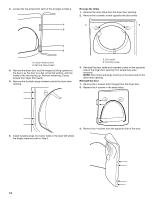

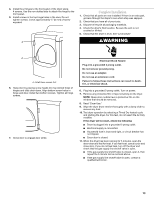

Vent system chart NOTE: Performance of rear exhaust to either side of the dryer is equivalent to adding one elbow. To determine maximum exhaust length, add one elbow to the chart. Number of 90º turns or elbows Type of vent Box or Louvered hoods Angled hoods 0 Rigid metal 64 ft (20 m) 58 ft (17.7 m) Flexible metal 36 ft (11 m) 28 ft (8.5 m) 1 Rigid metal 54 ft (16.5 m) 48 ft (14.6 m) Flexible metal 31 ft (9.4 m) 23 ft (7 m) 2 Rigid metal 44 ft (13.4 m) 38 ft (11.6 m) Flexible metal 27 ft (8.2 m) 19 ft (5.8 m) 3 Rigid metal 35 ft (10.7 m) 29 ft (8.8 m) Flexible metal 25 ft (7.6 m) 17 ft (5.2 m) 4 Rigid metal 27 ft (8.2 m) 21 ft (6.4 m) Flexible metal 23 ft (7 m) 15 ft (4.6 m) Install Vent System 1. Install exhaust hood. Use caulking compound to seal exterior wall opening around exhaust hood. 2. Connect vent to exhaust hood. Vent must fit inside exhaust hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp. 3. Run vent to dryer location. Use the straightest path possible. See "Determine vent path" in "Plan Vent System." Avoid 90º turns. Use clamps to seal all joints. Do not use duct tape, screws or other fastening devices that extend into the interior of the vent to secure vent. Install Leveling Legs WARNING Excessive Weight Hazard Use two or more people to move and install dryer. Failure to do so can result in back or other injury. 1. To protect the floor, use a large flat piece of cardboard from the dryer carton. Place cardboard under the entire back edge of the dryer. 2. Firmly grasp the body of the dryer (not the top or console panel). Gently lay the dryer on the cardboard. See illustration. 4. Screw the legs into the leg holes by hand. Use a wrench to finish turning the legs until the diamond marking is no longer visible. 5. Place a carton corner post from dryer packaging under each of the 2 dryer back corners. Stand the dryer up. Slide the dryer on the corner posts until it is close to its final location. Leave enough room to connect the exhaust vent or gas line. For mobile home use Gas dryers must be securely fastened to the floor. Mobile home installations require a Mobile Home Installation Kit. See "Tools and Parts" section for information on ordering. Make Gas Connection 1. Remove the red cap from the gas pipe. 2. Using a wrench to tighten, connect the gas supply to the dryer. Use pipe-joint compound on the threads of all nonflared male fittings. If flexible metal tubing is used, be sure there are no kinks. A B A. Flared male thread B. Non-flared male thread NOTE: For LP gas connections, you must use pipe-joint compound resistant to the action of LP gas. Do not use TEFLON®† tape. 3. Examine the leveling legs. Find the diamond marking. †®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company. 10