Brother International BE-1201B-AC Wiper Problems and Solutions - English - Page 5

Thread Presser Base Assembly, Checking the wiper solenoid - used

|

View all Brother International BE-1201B-AC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

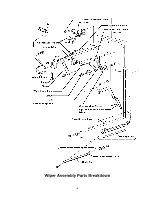

Checking the wiper solenoid Disconnect the wiper solenoid from the machine by following the cable out of the solenoid and unplugging at the connector on the machine. With an ohmmeter measure the resistance across the two pins of the solenoid connector that go to the solenoid. A good solenoid will measure approximately 23 ohms. Checking the voltage to the wiper solenoid Disconnect the wiper solenoid from the machine by following the cable from the solenoid and unplugging at the connector on the machine. Using a voltmeter set up to read a least +60 VDC. Connect it to the two pins of the connector from the machine. Press the trim button on the machine and it will read approximately +60VDC for about a second. Checking solenoid sensor alignment. Looking at the solenoid sensor, orientation will vary from machine type; you should see something that looks like this. If the sensor plate does not line up correctly then either the sensor or solenoid sensor plate needs to be adjusted until the alignment is as illustrated above. Checking upper thread guide hook (wiper) alignment. Color change machine to the highest needle bar number, 9 or 12, and lower presser foot. Manually lower the wiper down by pulling down on the screw that the bottom part of the return spring mounts to. The wiper should look as illustrated below in relation to the hole in the needle plate. If adjustment is required, loosen the two screws on the wiper and move it until it is correct. Recheck after adjustment. Wiper Needle Plate Checking thread presser base and cover alignment. First you want to make to inspect the thread presser cover to make sure it is straight and not bent. You should see an even spacing all the way across where the magic tape strips are. If not loosen the adjustment screw on the right and adjusted the thread presser cover until the spacing is the same all the way across. Thread Presser Base Assembly Spacer Thread Presser Cover Magic Tapes 5 Adjustment Screw Thread Presser Cover