Brother International LS2-F52A Instruction Manual - English - Page 25

Safety, Cluch, Mechanism, Caution

|

View all Brother International LS2-F52A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

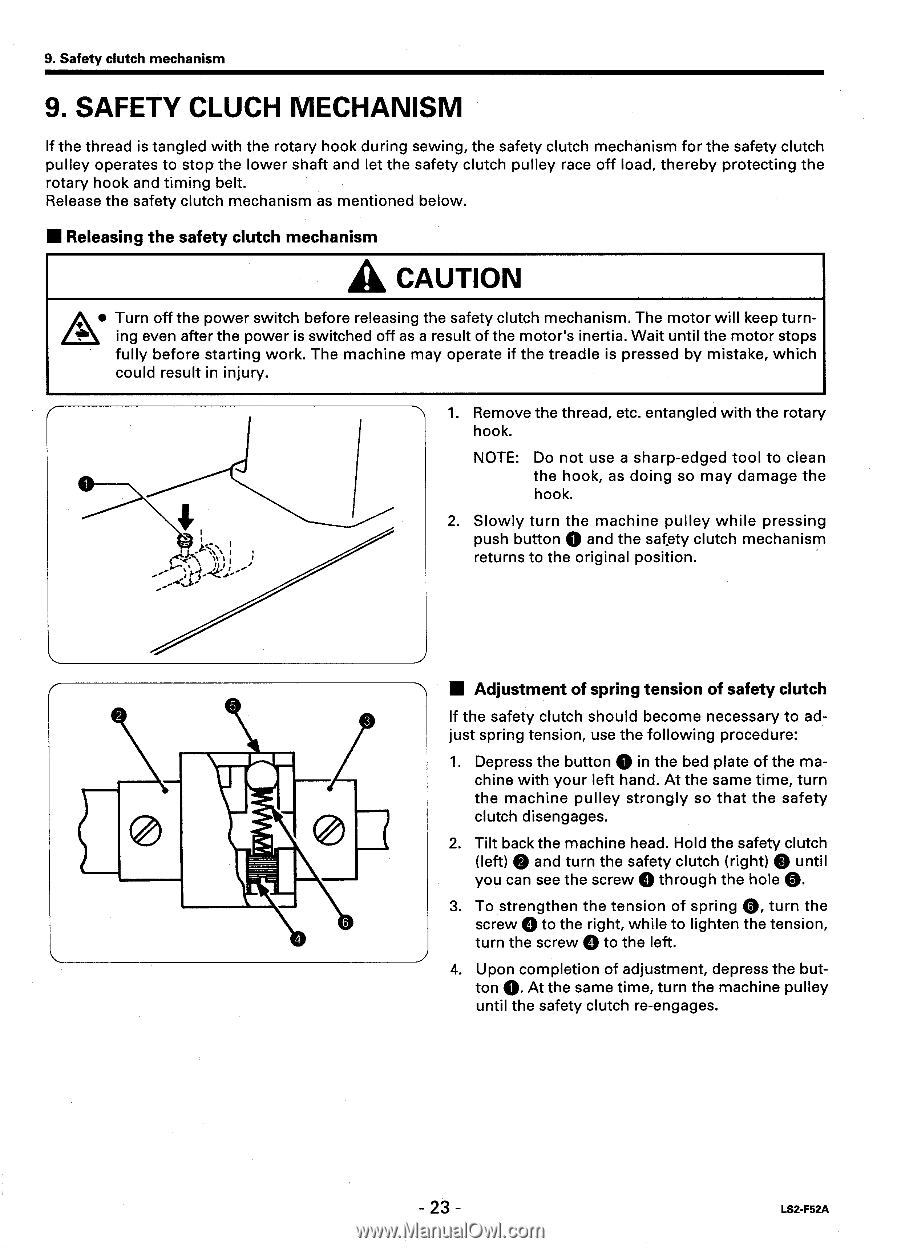

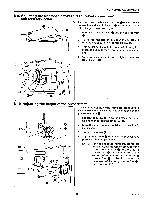

9. Safety clutch mechanism 9. SAFETY CLUCH MECHANISM If the thread is tangled with the rotary hook during sewing, the safety clutch mechanism for the safety clutch pulley operates to stop the lower shaft and let the safety clutch pulley race off load, thereby protecting the rotary hook and timing belt. Release the safety clutch mechanism as mentioned below. • Releasing the safety clutch mechanism A CAUTION • Turn off the power switch before releasing the safety clutch mechanism. The motor will keep turning even after the power is switched off as a result of the motor's inertia. Wait until the motor stops fully before starting work. The machine may operate if the treadle is pressed by mistake, which could result in injury. 1. Remove the thread, etc. entangled with the rotary hook. NOTE: Do not use a sharp-edged tool to clean the hook, as doing so may damage the hook. 2. Slowly turn the machine pulley while pressing push button 0 and the safety clutch mechanism 40, ,,eLs..s returns to the original position. • Adjustment of spring tension of safety clutch If the safety clutch should become necessary to adjust spring tension, use the following procedure: 1. Depress the button 0 in the bed plate of the machine with your left hand. At the same time, turn the machine pulley strongly so that the safety clutch disengages. 2. Tilt back the machine head. Hold the safety clutch (left) Q and turn the safety clutch (right) 0 until you can see the screw 0 through the hole 0. 3. To strengthen the tension of spring 0, turn the screw 0 to the right, while to lighten the tension, turn the screw 0 to the left. 4. Upon completion of adjustment, depress the button 0. At the same time, turn the machine pulley until the safety clutch re-engages. - 23 - LS2-F52A