Brother International PR-600 Users Manual - English - Page 190

Loosen the thumb screw for the mounting jig

|

View all Brother International PR-600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 190 highlights

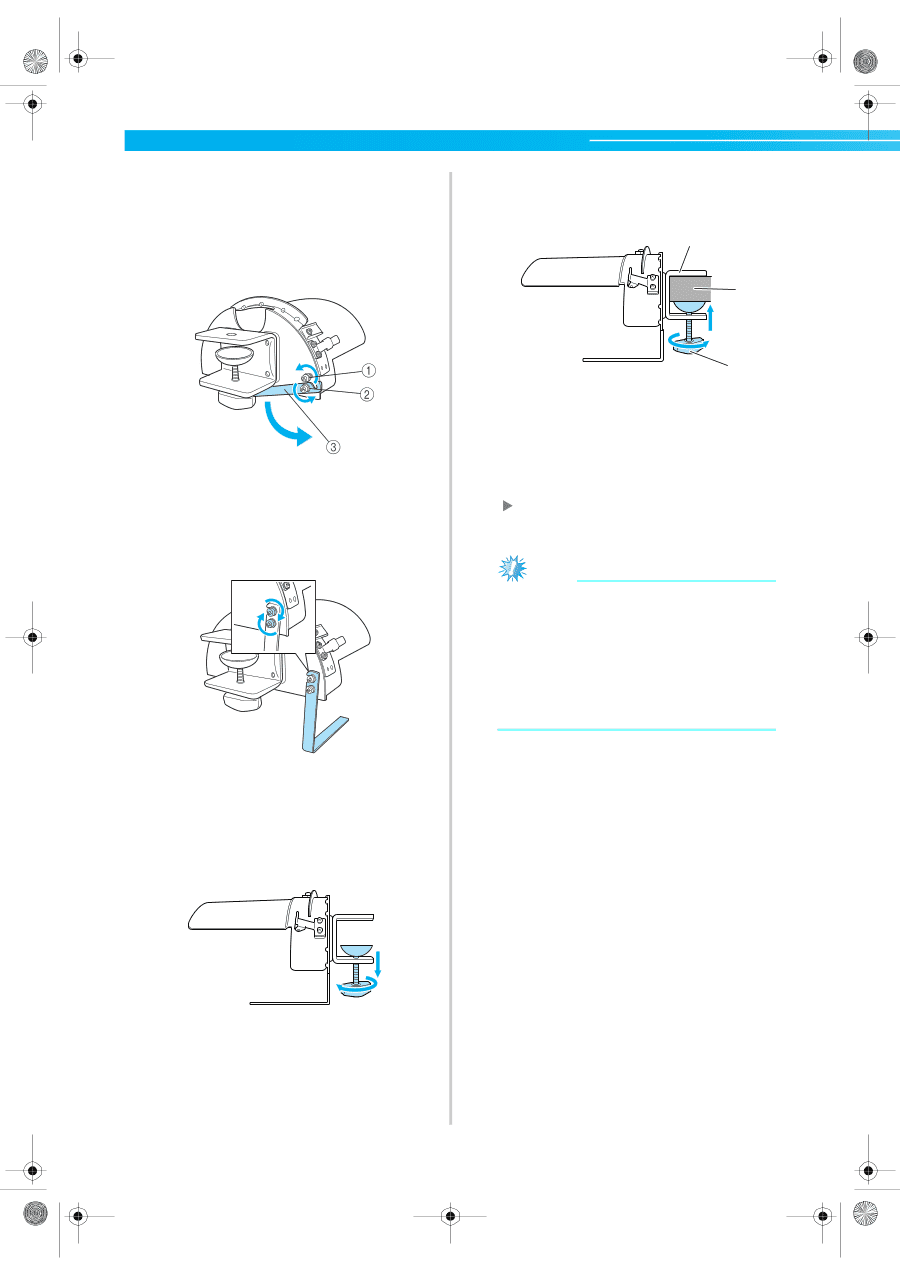

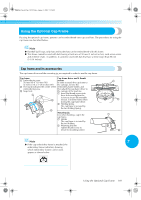

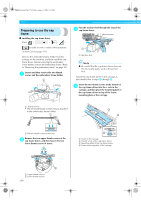

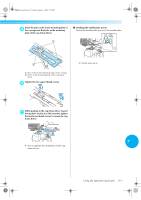

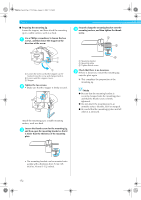

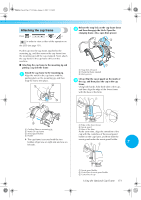

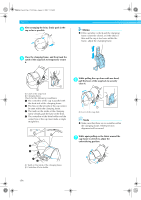

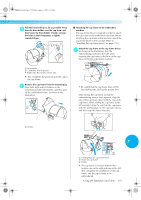

Sapphire.book Page 172 Friday, August 1, 2003 9:12 AM Appendix ■ Preparing the mounting jig Lower the stopper, and then attach the mounting jig to a stable surface, such as a desk. Use a Phillips screwdriver to loosen the two 1 screws, and then lower the stopper in the direction of the arrow. Securely clamp the mounting bracket onto the 4 mounting surface, and then tighten the thumb screw. 1 2 1 Loosen the screw so that the stopper can be hooked onto the screw and clamped with it. 2 Loosen until the stopper moves. 3 Stopper Tighten the two screws. 2 • Make sure that the stopper is firmly secured. 3 1 Mounting bracket 2 Mounting plate 3 Tighten thumb screw Check that there is no looseness. 5 If there is looseness, mount the mounting jig onto the plate again X This completes the preparation of the mounting jig. Note ● Be sure that the mounting bracket is securely clamped onto the mounting place and that the thumb screw is firmly tightened. ● Do not attach the mounting jig to an unstable surface (flexible, bent or warped). ● Be careful that the mounting jig does not fall when it is removed. Attach the mounting jig to a stable mounting surface, such as a desk. Loosen the thumb screw for the mounting jig, 3 and then open the mounting bracket so that it is wider than the thickness of the mounting plate. • The mounting bracket can be mounted onto a plate with a thickness from 9 mm (3/8 inch) to 38 mm (1-1/2 inches). 172