Brother International XR9550 Operation Manual

Brother International XR9550 Manual

|

View all Brother International XR9550 manuals

Add to My Manuals

Save this manual to your list of manuals |

Brother International XR9550 manual content summary:

- Brother International XR9550 | Operation Manual - Page 1

Operation Manual Sewing Machine Product Code: 888-E33/E34/E36/E37 KNOWING YOUR SEWING MACHINE SEWING BASICS UTILITY STITCHES APPENDIX Be sure to read this document before using the machine. We recommend that you keep this document nearby for future reference. - Brother International XR9550 | Operation Manual - Page 2

- Brother International XR9550 | Operation Manual - Page 3

, heat, discoloration or deformation, stop using the machine and immediately unplug the power cord. • When transporting the machine, be sure to carry it by its handle. Lifting the machine by any other part may damage the machine or result in the machine falling, which could cause injuries. • When - Brother International XR9550 | Operation Manual - Page 4

first follow the troubleshooting table in the back of the operation manual to inspect and adjust the machine yourself. If the problem persists, please consult your local authorized Brother dealer. Use this machine only for its intended use as described in this manual. Use accessories recommended by - Brother International XR9550 | Operation Manual - Page 5

IMPORTANT SAFETY INSTRUCTIONS 1 1. KNOWING YOUR SEWING MACHINE 4 ACCESSORIES 4 Included accessories 4 Optional accessories 5 Accessory compartment 5 Flip chart (For models equipped with a flip chart).... 5 NAMES OF MACHINE PARTS AND THEIR FUNCTIONS 6 The main parts 6 Needle and presser - Brother International XR9550 | Operation Manual - Page 6

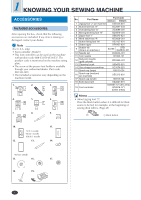

1 KNOWING YOUR SEWING MACHINE ACCESSORIES Included accessories After opening the box, check that the following accessories are included. If any item is missing or damaged, contact your dealer. Note (For U.S.A. only) • Foot controller: Model T • This foot controller can be used on the machine with - Brother International XR9550 | Operation Manual - Page 7

YOUR SEWING MACHINE Optional accessories For models equipped with an open type flat bed attachment The following are available as optional accessories to Open the compartment as illustrated below. be purchased separately. Depending on the model you purchased, the following accessory may - Brother International XR9550 | Operation Manual - Page 8

lever (page 37 and 42) G Presser foot lever (page 16) H Thread guide (page 12 and 17) I Thread guide cover (page 17) J Handle Carry the sewing machine by its handle when transporting the machine. Needle and presser foot section 1 Bobbin winder (page 11) 2 Upper tension-control dial (page 28 - Brother International XR9550 | Operation Manual - Page 9

needle. 4 Sewing speed controller Slide this controller to adjust the sewing speed. Operation panel The operation panel allows you to select a stitch and specify how the stitch will be sewn. The operation panel differs depending on the sewing machine the model. This manual uses the illustrations of - Brother International XR9550 | Operation Manual - Page 10

KNOWING YOUR SEWING MACHINE Spool pin Press down on the spool pin lever to raise the spool pin down until it locks into place. ■■Storing the spool pin When placing the cover on the sewing machine or if the spool pin will not be used, return the spool pin to its storage position. Press until it clicks - Brother International XR9550 | Operation Manual - Page 11

. 3 To turn off the machine, set the main power switch to "". XX The sewing light goes off when the machine is turned off. Note • If a power outage occurs while the sewing machine is being operated, turn off the sewing machine and unplug the power supply cord. (For U.S.A. only) • This appliance - Brother International XR9550 | Operation Manual - Page 12

the pressing force. Changing the needle stop position Normally, the sewing machine is set to leave the needle in the fabric when sewing is stopped. Instead, the machine can be set to leave the needle raised when sewing is stopped. 1 Turn off the sewing machine. 2 Holding the "-" side of (1) pressed - Brother International XR9550 | Operation Manual - Page 13

winding, see page 13. KNOWING YOUR SEWING MACHINE CAUTION • Only use the bobbin that comes with this machine or bobbins of the same type (part code: SA156, SFB: XA5539-151). Using other bobbins may cause damage to the machine. 1 SA156 is Class 15 type bobbin. Actual size 11.5 mm (7/16 inch - Brother International XR9550 | Operation Manual - Page 14

small for the spool, the thread may catch on the slit in the spool or the machine may be damaged. 3 Bobbin-winding thread guide Make sure that the thread passes under the pre-tension disk. 4 Memo • When sewing with fine, cross-wound thread, use the small spool cap, and leave a small space between - Brother International XR9550 | Operation Manual - Page 15

with the start/stop button). KNOWING YOUR SEWING MACHINE Memo • When the sewing machine is started or the handwheel is turned after winding the thread around the bobbin, the machine will make a clicking sound; this is not a malfunction. • The needle bar does not move when you slide the - Brother International XR9550 | Operation Manual - Page 16

poorly • Make sure you turn the power off while threading the machine. If you accidentally step on the foot controller and the machine starts to sew, you could be injured. Memo • The direction for feeding the bobbin thread is indicated by marks on the needle plate cover. Be sure to thread the - Brother International XR9550 | Operation Manual - Page 17

in the direction shown by the arrow. KNOWING YOUR SEWING MACHINE ■■For models equipped with the quick-set bobbin Memo • The direction for feeding the bobbin thread is indicated by marks on the needle plate cover. Be sure to thread the machine as indicated. 1 CAUTION • Make sure you set the - Brother International XR9550 | Operation Manual - Page 18

YOUR SEWING MACHINE 1 Slit 2 Cutter (Cut the thread with the cutter.) Note • If the thread is not correctly inserted through the tension-adjusting spring of the bobbin case, it may cause incorrect thread tension (page 27). CAUTION • When threading the upper thread, carefully follow the instructions - Brother International XR9550 | Operation Manual - Page 19

may become tangled if the bobbin winder is used without raising the spool pin. 5 Fully insert the spool for the upper thread onto the spool pin. Slide the spool cap onto the spool pin. KNOWING YOUR SEWING MACHINE 6 Pass the thread as illustrated below. 1 1 Thread guide • The thread should be - Brother International XR9550 | Operation Manual - Page 20

sure to raise the needle before threading the sewing machine. 9 Put the thread behind the needle bar thread guide. 1 1 Needle bar thread guide 10 Turn off the sewing machine. CAUTION • Make sure you turn the power off while threading the machine without using the needle threader (for models equipped - Brother International XR9550 | Operation Manual - Page 21

foot lever. 1 Presser foot lever 7 Pass the end of the thread as illustrated bellow. KNOWING YOUR SEWING MACHINE or 1 1 Turn the handwheel so that the mark on the wheel points up. 2 Press the Needle position button (for the models equipped with this button). 3 Pull on the upper thread to draw - Brother International XR9550 | Operation Manual - Page 22

dangerous. CAUTION • Only use home sewing machine needles. Use of any other needle may bend the needle or damage the machine. • Never use bent needles. Bent needles can easily break, possibly resulting in injury. Needle types and their uses The sewing machine needle that should be used depends on - Brother International XR9550 | Operation Manual - Page 23

• Do not apply strong force when loosening or tightening the needle clamp screw, otherwise certain parts of the sewing machine may be damaged. 1 1 Turn the handwheel so that the mark on the wheel points up. 2 Press the Needle position button (for the models equipped with this button). 2 Turn - Brother International XR9550 | Operation Manual - Page 24

YOUR SEWING MACHINE CAUTION • Use only twin needles that have been made for this machine (part code: 131096-121). Other needles could break, and damage the machine. • Do not sew with bent needles. The needle could break and injure you. • You cannot use the needle threader to thread the twin needle - Brother International XR9550 | Operation Manual - Page 25

the presser foot, be sure to 1 turn off the sewing machine, otherwise injuries may occur if the foot controller or the start/ Note stop button is accidentally pressed and the machine starts sewing. • When using the twin needle, the stitches may become bunched together, depending on the types - Brother International XR9550 | Operation Manual - Page 26

securely attached. Removing the presser foot holder Remove the presser foot holder when cleaning the sewing machine or when installing a presser foot that does not use the presser foot holder, such foot holder may fall off and the needle may strike it, causing the needle to bend or break. 24 - Brother International XR9550 | Operation Manual - Page 27

type differs depending on the model. This manual uses the illustrations of type A LCD. For models equipped with type A LCD For models equipped with type B LCD Selecting a stitch When the sewing machine is turned on, the straight stitch ( left needle position) is selected. 1 Presser foot type • For - Brother International XR9550 | Operation Manual - Page 28

Press (stitch selection keys) to select stitch 04. Starting to sew 1 Raise the needle in the following way. or 2 Press the "+" or "-" side then pull out about 5 cm (2 inches) of thread toward the rear of the machine. 1 Stitch width 3 Narrow 2 Stitch width adjustment key 4 Wide Note • When - Brother International XR9550 | Operation Manual - Page 29

the start/stop button). • When sewing is stopped, the needle remains lowered (in the fabric). The machine can be set so that the needle will stay up when sewing is stopped. For details, refer to "Changing the needle stop position" (page 10). Note • If the bobbin thread was incorrectly threaded, the - Brother International XR9550 | Operation Manual - Page 30

to a lower number. 54 3 Memo • When you finish sewing, remove the bobbin cover and then make sure that the thread is shown as below sewing direction 1 When the stitching reaches a corner, stop the sewing machine. Leave the needle lowered (in the fabric). If the needle was raised, lower the needle - Brother International XR9550 | Operation Manual - Page 31

if the fabric is pushed with too much force, the needle may bend or break. Sewing hook-and-loop fastener tape CAUTION • Use only the ungummed hook-and-loop fastener tape which is for sewing. If the glue is attached to the needle or the bobbin hook race, it may cause malfunction. • If the hook - Brother International XR9550 | Operation Manual - Page 32

type flat bed attachment> 1 Edge of the hook-and-loop fastener tape Sewing thin fabrics When sewing thin fabrics, the stitching may become misaligned or the fabric may not feed correctly. Move the needle (be sure to use a fine needle) to the furthest left or right hand position so that the fabric - Brother International XR9550 | Operation Manual - Page 33

the handwheel toward you (counterclockwise) and check that the needle does not touch the presser foot. 3 5 Sew with the edge of the fabric against the presser foot guide. J 09 1 CAUTION • Be sure to turn off the main power before replacing the presser foot. Otherwise, injuries may occur - Brother International XR9550 | Operation Manual - Page 34

the foot controller or (start/ stop button) is accidentally pressed and the machine starts sewing. Basic stitching 1 Baste or pin together the fabric pieces. 2 Attach zigzag foot "J". 3 Select a stitch. (Refer to page 25.) 4 Lower the needle into the fabric at the beginning of the stitching. 5 Start - Brother International XR9550 | Operation Manual - Page 35

with the edge of the folded hem against the guide of the presser foot, and then part that you wish to sew onto the arm, make sure that the fabric feeds correctly, and then start sewing. 1 Thick fabric 2 Normal fabric ■■If the needle catches too much of the hem fold If the needle - Brother International XR9550 | Operation Manual - Page 36

foot guide. 13 Remove the basting stitching and turn the fabric right side up. 1 2 CAUTION • Be sure to turn off the main power before replacing the presser foot. Otherwise, injuries may occur if the foot controller or (start/ stop button) is accidentally pressed and the machine starts sewing - Brother International XR9550 | Operation Manual - Page 37

presser foot lever. 1 1 Marks on fabric 2 Buttonhole sewing 2 Pull out the button guide plate of buttonhole foot "A", and then insert the button that aligning the marks, slowly turn the handwheel toward you to check where the needle will enter the fabric, and then align the mark on the fabric with - Brother International XR9550 | Operation Manual - Page 38

needle to pull the gimp thread to the wrong side of the fabric, and then tie it. 8 With a seam ripper, cut the middle part of the gimp thread remaining at the top end of the buttonhole. Trim off any excess of the gimp thread. Button sewing Buttons can be sewn on with the sewing machine - Brother International XR9550 | Operation Manual - Page 39

scissors to cut the upper thread and the bobbin thread at the beginning of the stitching. • When attaching four-hole buttons, first sew the two holes closest to you. Then, slide the button so that the needle goes into the other two holes, and then sew them in the same way. 11 When you - Brother International XR9550 | Operation Manual - Page 40

UTILITY STITCHES CAUTION • Be sure to turn off the main power before replacing the presser foot. Otherwise, injuries may occur if the foot controller or (start/ stop button) is accidentally pressed and the machine starts sewing. 1 Attach zigzag foot "J". 2 Place the two pieces of fabric with their - Brother International XR9550 | Operation Manual - Page 41

power before right hand. replacing the presser foot. Otherwise, injuries may occur if the foot controller or (start/ stop button) is accidentally pressed and the machine starts sewing CAUTION • When sewing, be sure that the needle does not touch any pins, otherwise the needle may bend or break - Brother International XR9550 | Operation Manual - Page 42

areas that will be sewn with the machine. If glue is attached to the needle or race, the machine may be damaged. 2 Attach zigzag foot "J". 3 Select stitch . 4 Sew along the edge of the fabric with the needle dropping off the edge at the right. Piecing Sewing together two pieces of fabric is called - Brother International XR9550 | Operation Manual - Page 43

the handwheel toward the front of the machine to check that the needle does not strike the presser foot. If the needle strikes the presser foot, injury may refer to "Changing the needle position" (page 32). foot, and then evenly guide the fabric while sewing. 3 Quilting Sandwiching batting - Brother International XR9550 | Operation Manual - Page 44

needle threader • Thread the needle manually when using the quilting foot, or only attach the quilting foot after threading the needle using the needle foot should be positioned over the needle clamp screw. XX The feed dogs are lowered. 5 Turn on the sewing machine, and then select a stitch. - Brother International XR9550 | Operation Manual - Page 45

needle drops 2 mm (1/16 inch) in front of the pocket opening. CAUTION • Be sure to turn off the main power before replacing the presser foot. Otherwise, injuries may occur if the foot controller or (start/ stop button) is accidentally pressed and the machine starts sewing the button guide plate on - Brother International XR9550 | Operation Manual - Page 46

XX Once sewing is completed, the machine automatically sews reinforcement stitches, then stops. 7 Raise the needle and the power before replacing the presser foot. Otherwise, injuries may occur if the foot controller or (start/ stop button) is accidentally pressed and the machine starts sewing - Brother International XR9550 | Operation Manual - Page 47

parallel stitching at intervals of 10 mm 3 (3/8 inch). 1 1 10 mm (3/8 inch) • Do not sew reverse/reinforcement stitches or cut the thread. 4 Pull the bobbin threads to create gathers. Smooth the gathers by ironing them. 5 Select stitch or . 6 Stitch between the straight stitches. • For better - Brother International XR9550 | Operation Manual - Page 48

thin or medium weight fabrics in addition to plain weave fabrics. CAUTION • The needle threader cannot be used with the wing needle, otherwise the sewing machine may be damaged. Manually pass the thread through the eye of the needle from the front to the back. For details, refer to "Upper threading - Brother International XR9550 | Operation Manual - Page 49

Needles and threads When sewing thin, mediumweight or stretch fabrics, use the ball point needle. When sewing thick fabrics, use a 90/14 home sewing machine needle . Be sure to sew a trial piece of fabric before sewing your project. In addition, while sewing, be sure to guide the fabric with your - Brother International XR9550 | Operation Manual - Page 50

stitches" (page 50). Memo • The combination of characters will be stored in memory even if you turn off the machine. ■■Adding new characters after sewing After sewing a combination of characters, you can add characters to the combination using the following method. Memo • When you have finished - Brother International XR9550 | Operation Manual - Page 51

character. 3 XX New characters are added next to the last character of the combination. ■■Making a new combination of characters after sewing Memo • When you have finished sewing, the pattern No. of the first character in the current combination is shown on the LCD. 1 Stitch length adjustment key - Brother International XR9550 | Operation Manual - Page 52

. 1 Attach monogramming foot "N". XX The stitch is sewn in the direction indicated by the arrow. Memo • When sewing characters, the machine automatically sews reinforcement stitches for each character. • While sewing, the LCD shows the pattern No. currently being sewn. 4 When you have finished - Brother International XR9550 | Operation Manual - Page 53

• The stitch adjustment level can be set between -9 and 9. • The setting is saved in memory even if you turn off the machine. 6 Sew the characters "034" again. Memo • You can sew when you are in the stitch adjustment mode. If the stitch pattern still comes out poorly, adjust the stitch again. Adjust - Brother International XR9550 | Operation Manual - Page 54

needle, be sure to attach zigzag foot "J", otherwise the needle may break or the machine may be damaged. Note • The walking foot can only be used with straight or zigzag stitch patterns. Do not sew Length [mm (inch)] [mm (inch)] Auto Manual 0.0 (0) 0.0-7.0 (0-1/4) 3.5 (1/8) 0.0-7.0 (0-1/4) 0.0 - Brother International XR9550 | Operation Manual - Page 55

Needle Reverse (Rev.)/ Reinforcement (Reinf.) Stitching Stitch Name Pattern No. Application Stitch Width Stitch Length [mm (inch)] [mm (inch)] Auto Manual Auto Manual Patchwork stitching, decorative stitching and 5.0 (3/16) 16 sewing overcasting on both pieces of fabrics, 2.5-7.0 such as - Brother International XR9550 | Operation Manual - Page 56

for the upper thread and a thread color 45 matching the quilt for the bobbin thread. Sew with a tight thread tension so that the bobbin thread is visible from the right side of 0.0 (0) 0.0-7.0 (0-1/4) the fabric. Use a needle between 90/14 and 100/16. 2.5 (3/32) 1.0-4.0 (1/16-3/16) No Reinf - Brother International XR9550 | Operation Manual - Page 57

Pattern Presser Foot Twin Needle Reverse (Rev.)/ Reinforcement (Reinf.) Stitching Stitch Name Pattern No. Application or less. APPENDIX Stitch Width Stitch Length [mm (inch)] [mm (inch)] Auto Manual Auto Manual 7.0 (1/4) 0.0-7.0 (0-1/4) 1.6 (1/16) 0.2-4.0 (1/64-3/16) No Reinf. 7.0 (1/4) - Brother International XR9550 | Operation Manual - Page 58

Pattern Presser Foot Twin Needle Reverse (Rev.)/ Reinforcement (Reinf.) Stitching APPENDIX Stitch Name Pattern 6.0 (15/64) 0.0-7.0 (0-1/4) 6.0 (15/64) 0.0-7.0 (0-1/4) 6.0 (15/64) 0.0-7.0 (0-1/4) Auto Manual 0.4 (1/64) 0.1-1.0 (1/64-1/16) 0.4 (1/64) 0.1-1.0 (1/64-1/16) 0.4 (1/64) 0.1-1.0 (1/64-1/ - Brother International XR9550 | Operation Manual - Page 59

model 11 0 stitches model Twin Needle Reverse (Rev.)/ Reinforcement (Reinf.) Stitching Stitch Name Pattern No. Application Stitch Width Stitch Length [mm (inch)] [mm (inch)] Auto Manual Auto Manual Stretch stitch J 00 00 00 Sewing stretch fabrics and decorative stitching 1.0 (1/16 - Brother International XR9550 | Operation Manual - Page 60

Pattern Presser Foot 13 0 stitches model 12 0 stitches model 11 0 stitches model Twin Needle Reverse (Rev.)/ Reinforcement (Reinf.) Stitching APPENDIX Stitch Name Pattern No. Application N 19 19 mm (3/16 inch) or less. Stitch Width Stitch Length [mm (inch)] [mm (inch)] Auto Manual Auto Manual - Brother International XR9550 | Operation Manual - Page 61

APPENDIX Character stitches (for models equipped with character stitches) Presser Foot Twin Needle Stitch Width/ Stitch Length Stitch Type Pattern No. Character stitches 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 - Brother International XR9550 | Operation Manual - Page 62

it once with a wet cloth, wipe it again with a dry cloth. CAUTION • Unplug the power supply cord before cleaning the machine, otherwise injuries or an electric shock may occur. Cleaning the race Sewing performance will suffer if dust collects in the race therefore, it should be cleaned periodically - Brother International XR9550 | Operation Manual - Page 63

that the needle plate cover is flush with the top surface of the machine. TROUBLESHOOTING If the machine stops operating correctly, check the following possible problems before requesting service. You can solve most problems by yourself. If you need additional help, the Brother Solutions Center - Brother International XR9550 | Operation Manual - Page 64

2 Remove the upper thread from the machine. 3 Correct the upper threading by following the instructions in "Upper threading" (page 16). • If the bobbin was removed from the bobbin case, refer to "Lower threading" fabric is loose or has slack. • After starting sewing, a rattling noise is made and - Brother International XR9550 | Operation Manual - Page 65

sewing machine and cannot be removed, the thread may have become tangled under the needle plate. Follow the procedure described below to remove the fabric from the machine 1 Needle plate cover release 2 Needle plate cover (front part) 7 Cut out the tangled threads, and then remove the bobbin. 54 3 - Brother International XR9550 | Operation Manual - Page 66

dogs 2 Incorrect position of feed dogs Note • Be careful not to drop the removed screws in the machine. 16 Insert the bobbin case by following step 7 in "Cleaning the race" (page 61). 17 Attach the needle plate cover by following steps 8 and 9 in "Cleaning the race" (page 61). 18 Check the condition - Brother International XR9550 | Operation Manual - Page 67

fabric from the machine" (page 64). Error message "E6" appears in the LCD If the error message "E6" appears in the LCD with the occurrence of one of the following symptoms, follow the procedure below to solve the problem. Symptom 1 : The machine rattles and then stops just after sewing is started - Brother International XR9550 | Operation Manual - Page 68

, the upper thread cannot be threaded correctly. Be sure to raise the needle before threading the sewing machine. ■■Remedy Thread the upper thread again correctly by following the procedure below. 1 Turn off the machine. 2 If the thread is tangled, remove the tangled thread. • Refer to "Cleaning - Brother International XR9550 | Operation Manual - Page 69

the needle. page 16 page 21 The sewing light does not come on. The machine is not turned on. Turn on the machine. page 9 The thread is not passed through the Correctly pass the thread through the bobbin-winding thread guide correctly. bobbin-winding thread guide. page 11 Bobbin thread - Brother International XR9550 | Operation Manual - Page 70

. Only use a bobbin that has been designed for this machine. page 11 The upper thread was not threaded correctly. (for example, the spool is not installed correctly, the spool cap is too big for the spool being used, or the thread has come out of the needle bar thread guide.) Correct the upper - Brother International XR9550 | Operation Manual - Page 71

a burr on it. Replace the bobbin case. Contact your retailer or the nearest authorised service center. - You have not used a bobbin that has been designed for this machine. Incorrect bobbins will not work properly. Only use a bobbin that has been designed for this machine. page 11 You have not - Brother International XR9550 | Operation Manual - Page 72

bobbin case. sewing. The bobbin case is scratched. Contact your retailer or the nearest authorized service center. page 16 - You have not used bobbin that has been designed for this machine. Incorrect bobbins to sew. page 60, 62 page 52 The needle is bent or blunt. Replace the needle. page - Brother International XR9550 | Operation Manual - Page 73

thread (page 60). Check the needle. If the needle is bent or broken, replace the needle (page 21). If both of the above fail, refer to "Error message "E6" appears in the LCD" (page 65). The machine may be malfunctioning. Contact your nearest authorized service center. Operation beep Each time - Brother International XR9550 | Operation Manual - Page 74

46 L lower threading 14 M main parts 6 main power switch 9 mirror image stitch indicator 7, 25 N needle 20 needle bar thread guide 6, 18 needle clamp screw 6, 21 needle plate 6 needle plate cover 6, 60 needle position 10 needle position button 7, 26 needle threader 6, 18 72 O operation - Brother International XR9550 | Operation Manual - Page 75

- Brother International XR9550 | Operation Manual - Page 76

Please visit us at http://support.brother.com/ where you can get product support and answers to frequently asked questions (FAQs). English 888-E33/E34/E36/E37 Printed in Vietnam XG7396-001

APPENDIX

UTILITY STITCHES

SEWING BASICS

KNOWING YOUR

SEWING MACHINE

Operation Manual

Product Code: 888-E33/E34/E36/E37

Sewing Machine

Be sure to read this document before using the machine.

We recommend that you keep this document nearby for future reference.